A kind of preparation method of high-performance composite carbon felt

A composite carbon, high-performance technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of poor performance of a single VRB, poor hydrophilicity of carbon felt, and low electrochemical activity, and achieve improved conductivity and good stability. , the effect of high electrochemical catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

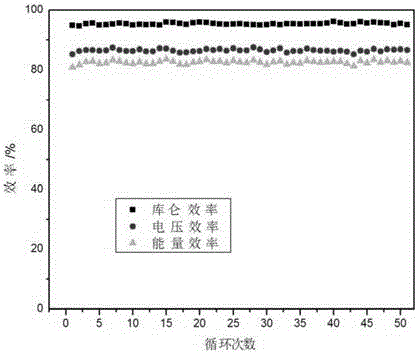

Examples

Embodiment 1

[0034] A kind of preparation method of high-performance composite carbon felt that the present invention proposes, comprises the following steps:

[0035] 1. Preparation of functionalized carbon nanotubes: first put 200mg of dried carbon nanotubes into 500-1000ml of deionized water, stir for 20-30 minutes; then weigh 600mg of p-aminobenzenesulfonic acid, stir for 1h, then add 2ml Hydrochloric acid, heat the above solution in water at 30°C for 3h; weigh 1g of sodium nitrite and add it to the above solution, react in water at 30°C for 3h; Then dry at 50°C to obtain functionalized carbon nanotubes.

[0036] 2. Preparation of functionalized carbon nanotube solution: Weigh 50 mg of functionalized carbon nanotubes, add 150 ml of deionized water, then add 5 ml of Nafion solution with a mass fraction of 5%, ultrasonicate for 30 minutes, then stir for 2 hours before use.

[0037] 3. Preparation of modified carbon felt: 500mg carbon felt was vacuum-dried at 70°C for 6 hours, then soake...

Embodiment 2

[0042] The difference from Example 1 is:

[0043] 1. During the preparation of the functionalized carbon nanotubes, the mass of the carbon nanotubes becomes 400 mg.

[0044] 2. The composite carbon felt was prepared in the same steps as in Example 1.

[0045] The internal resistance of the separator in the all-vanadium redox flow battery measured at room temperature is 0.85Ω / cm 2 , the surface resistance of the composite film prepared at this ratio is higher than that of the original carbon felt (0.68Ω / cm 2 ), the performance of the battery in VRB is similar to that of the original carbon felt, which is suitable for the application requirements of VRB. The carbon nanotubes prepared in this ratio have a low degree of functional grouping, so the proton conductivity and hydrophilic performance are reduced, and the voltage efficiency will be reduced during the charging and discharging process of the battery.

Embodiment 3

[0047] The difference from Example 1 is:

[0048] 1. Add 20 mg of functionalized carbon nanotubes to the preparation of the functionalized carbon nanotube solution.

[0049] 2. The composite carbon felt was prepared in the same steps as in Example 1.

[0050]During the preparation process, due to the reduced addition of functionalized carbon nanotubes, under the same conditions, the loading of functionalized carbon nanotubes on the composite electrode decreases, so the proton conductivity of the composite electrode will decrease, which is lower than that of Example 1. Therefore, the internal resistance of the separator in the all-vanadium redox flow battery measured at room temperature is 0.62Ω / cm 2 , the surface resistance of the composite film prepared at this ratio is lower than that of the original carbon felt (0.68Ω / cm 2 ), the battery voltage efficiency in VRB is higher than that of original carbon felt, which basically meets the application requirements of VRB. Howev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com