Health supplement food containing pediococcus acidilactici j9, and method for manufacturing same

A health food and food technology, applied in the direction of food preparation, microbe-based methods, biochemical equipment and methods, etc., can solve the problems of not developing health food, etc., and achieve the goals of increasing stability and lifespan, cultivating efficiently, and increasing production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] (Example 1) Utilize Pediococcus lactis J9 bacterial strain (KCCM 11320P) to produce food

[0030] The process of producing grain-fermented enzyme-containing products by inoculating the Pediococcus lactis J9 (KCCM 11320P) strain is as follows: the grains used as the main materials are 60% brown rice and soybeans, and black rice, barley and sorghum are added in order to improve the taste, This makes the total weight of the grain 200kg. Soak the grains in water for 12 hours. After washing the grains are cooked in a steamer for about 40 minutes under steam. Cool the cooked grains. Pediococcus lactis J9, Bacillus subtilis and Bacillus pumilus were cultured in flasks at an amount of 0.1% relative to the total weight of the grain. Adjust the number of each microorganism to 1.0 × 10 9 CFU / g. The microbial culture solution was mixed with 2 L of distilled water, and the cooked grain was inoculated with this mixture. The inoculated grains were stacked in plastic boxes, and t...

example 2

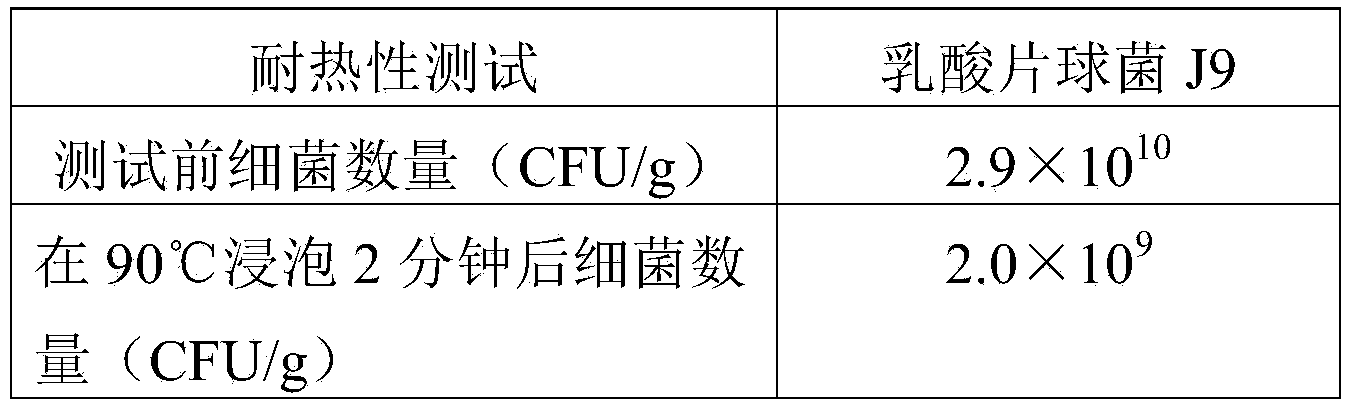

[0031] (Example 2) Measurement of the number of microorganisms of the genus Pediococcus lactis J9 and Bacillus that increased in value

[0032] Add 9ml of sterile saline to every 1mg sample and add 10 -7 Measure the number of Pediococcus lactis J9 by counting the number of yellow colonies after 70 hours of culture on plate count agar with BCP. Bacillus microorganisms were cultured in nutrient broth agar medium, and white colonies were counted in the same manner as above. The number of bacteria is shown in Table 1 below.

[0033] Table 1

[0034]

[0035] As can be seen from the above table 1, the microorganisms in the sample of every 1g can proliferate well to about 10 9 indivual. In addition, the formation of natural antibiotics (bacteriocin, epdiosin) as well as enzymes as secondary metabolites during the proliferation of microorganisms is a well-known technique.

example 3

[0036] (Example 3) Test of the antibacterial activity of Pediococcus lactis

[0037] Pediococcus lactis was cultivated, and then the concentration of the bacteria was measured using the Quick Start Bovine Serum Albumin (BSA) Standard Kit (Bio-Rad, USA). As a result, the concentration of bacteria was found to be 0.465 mg / ml. Spin at 15,000 rpm for 5 minutes to concentrate the culture solution, and collect the supernatant. Then, the residue was filtered with a 0.2 micron filter (Milipore, USA) to remove bacteria, thereby preparing an extract of Pediococcus lactis. Using the standard plate comparison method in CO at 37°C 2 The six standard strains shown in Table 2 below were cultured in a constant temperature incubator for about 24 hours.

[0038] Table 2

[0039]

[0040] 1

[0041] Single colony forming units of each standard strain were inoculated on blood agar plates and inoculated with 5 μl, 10 μl, 20 μl and 100 μl of Pediococcus lactis extract. Pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com