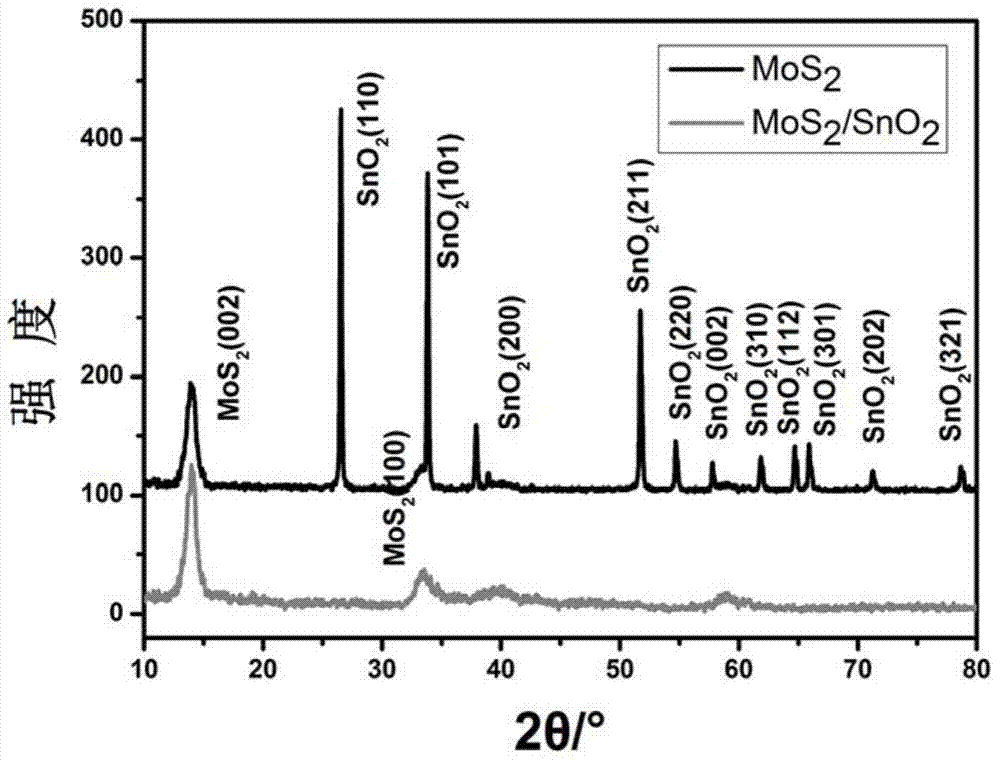

Three-dimensional MoS2 / SnO2 heterogeneous semiconductor nano material and preparation method thereof

A nanomaterial and semiconductor technology, applied in the field of three-dimensional MoS2/SnO2 heterogeneous semiconductor nanomaterials and its preparation, can solve the problems of inapplicability to large-scale industrial production, high production costs, harsh reaction conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

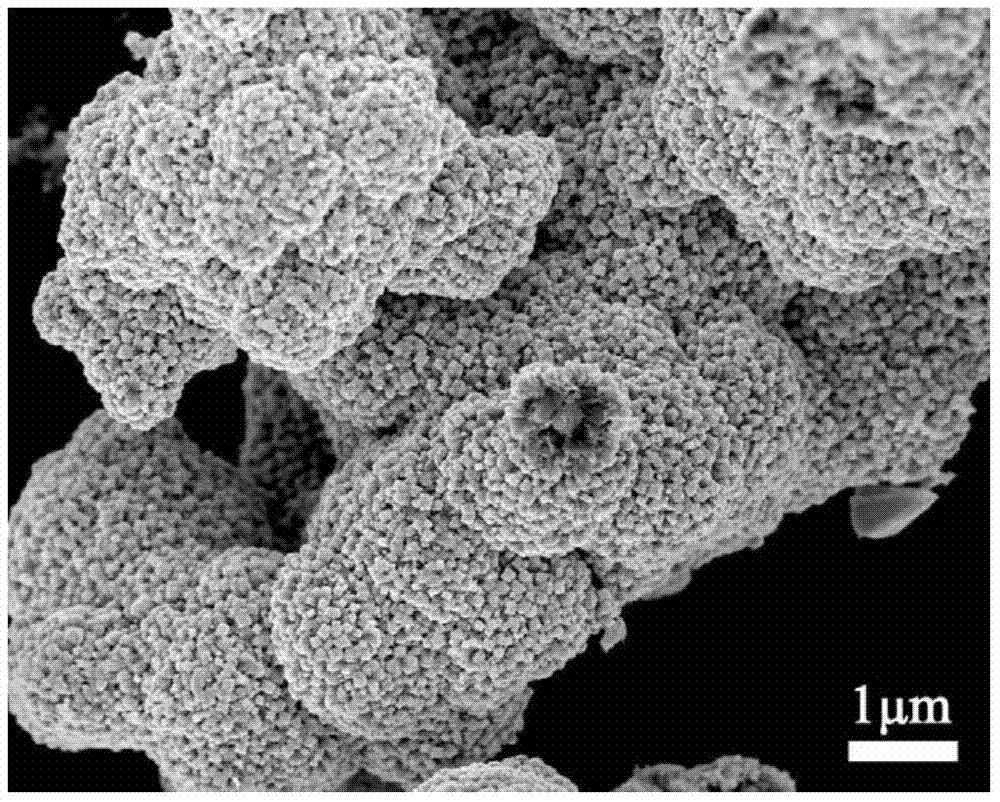

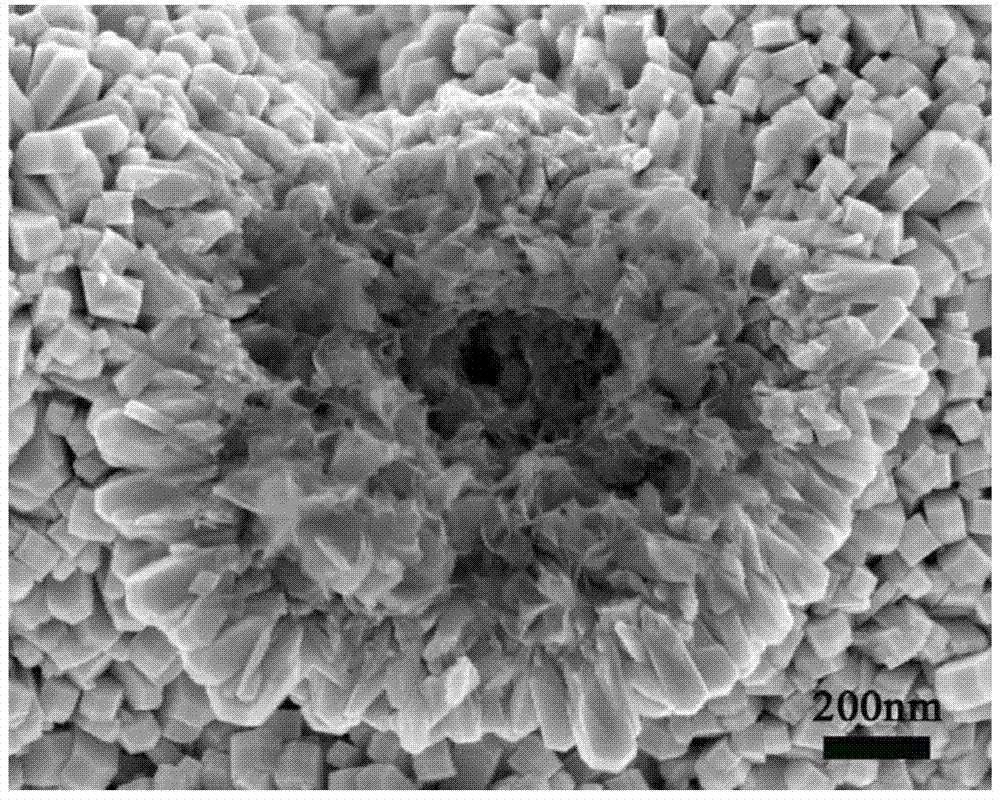

[0031] Example 1 Three-dimensional MoS of the present invention 2 / SnO 2 Fabrication of heterogeneous semiconducting nanostructures

[0032] The concrete steps of preparation method are as follows:

[0033] a. Mix 1.0g of sodium molybdate, 1.2g of thiourea and 0.4g of oxalic acid and dissolve in 80mL of deionized water, and stir thoroughly for 20 minutes.

[0034] b. Then transfer the mixed solution into a 100mL reaction kettle, place the reaction kettle in a vacuum oven and heat it at 200°C for 24 hours. When the reaction is completed and cooled to room temperature, collect the black reaction product and wash it repeatedly with deionized water and absolute ethanol Several times until the supernatant is completely clear.

[0035] c. Pour off the supernatant, dry the pure sample in a vacuum oven at 60° C. for 5 hours, and then take it out to obtain a black powder.

[0036] d. Place the black powder in a vacuum furnace protected by pure argon, burn it at 850°C for 2 hours, a...

Embodiment 2

[0041] Embodiment 2 The three-dimensional M of the present invention o Preparation of S2 / SnO2 Hetero-Semiconductor Nanostructures

[0042] In this example, step a is to mix 1.0g of sodium molybdate, 1.2g of thiourea and 0.25g of oxalic acid, dissolve them in 80mL of deionized water, and stir them thoroughly for 25 minutes. Other implementation steps and conditions of this example and implementation Example 1 is the same. The three-dimensional MoS prepared in this example 2 / SnO 2 The heterogeneous semiconductor nanostructure is similar to the product of Example 1.

Embodiment 3

[0043] Example 3 Three-dimensional MoS of the present invention 2 / SnO 2 Photocatalytic Performance Test of Heterogeneous Semiconductor Nanostructures

[0044] The three-dimensional MoS of the present invention prepared in Example 1 above 2 / SnO 2 Heterogeneous semiconductor nanostructures, due to their large specific surface area and the formation of p-n junctions at the junction, make them comparable to MoS 2 For the nanoflower structure, the photocatalytic performance has been significantly improved. Three-dimensional MoS of the present invention 2 / SnO 2 Heterogeneous semiconductor nanostructures and MoS 2 Photocatalytic performance test of nanoflower structure, including specific steps:

[0045] a. Take two identical brown jars, put 100ml of methylene blue solution in each bottle, the solution concentration is 10mgL -1 .

[0046] b. Take the three-dimensional MoS of the present invention respectively 2 / SnO 2 Heterogeneous semiconductor nanostructures and MoS ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com