Textured coating

A technology of textured coatings and raw materials, applied in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of narrow application range, low adhesion, and easy seams, etc., and achieve long open time , Complicated operation, and the effect of increasing water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

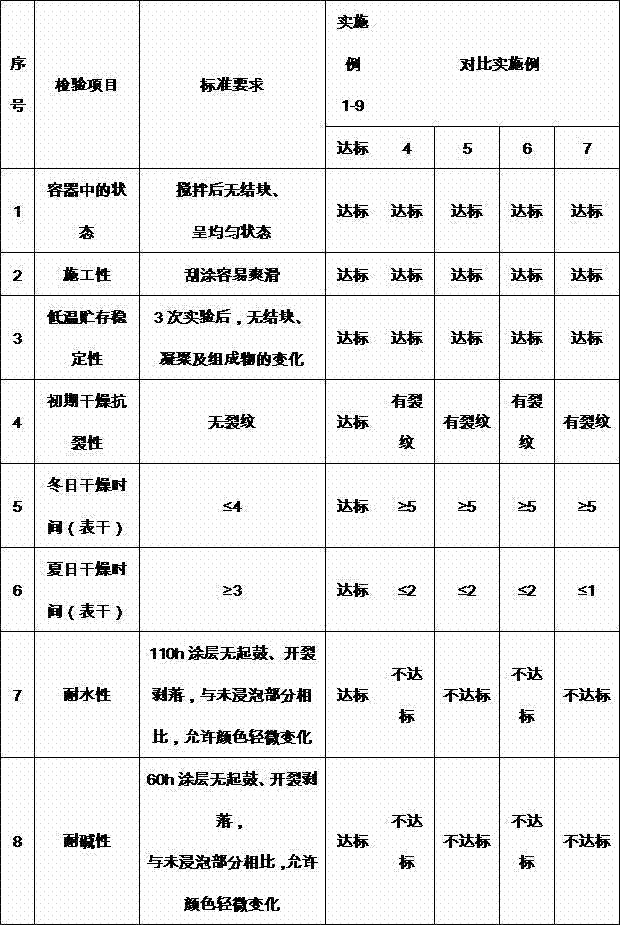

Examples

Embodiment 1

[0072] Texture paint formula: 10 parts of water, 40 parts of composite latex, 15 parts of quartz sand, 8 parts of silicon-based active glue, 6 parts of putty, 12 parts of cellulose ether, 2 parts of anti-mold preservative, 1 part of organic zirconium complex, 3 parts of dimethylaniline, 7 parts of pentaerythritol, 6 parts of lignocellulose airgel liquid;

[0073] Wherein, the composite latex contains 10% polyurethane resin, 50% polyacrylate resin, 20% polyvinyl alcohol resin, 15% epoxy resin, and 5% emulsifier.

[0074] The putty is formulated according to the putty recipe one.

[0075] The preparation method of lignocellulose airgel liquid is:

[0076] a. Pulverization: Lignocellulosic biomass is pulverized and sieved;

[0077] b. Purification: dissolving the crushed and sieved lignocellulosic biomass in an alkaline aqueous solution system composed of polyethylene glycol, sodium hydroxide and water at a mass ratio of 60:1:100 for degradation and purification for 12 hours, s...

Embodiment 2

[0085] The putty is according to the formula of putty formula 2.

[0086]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com