Surface growth type culture plate, culture unit and culture system and method

A surface growth and culture system technology, applied in the field of surface growth culture plates, can solve the problems of microalgae pollution, poor water absorption and water retention performance, low mechanical strength, etc., and achieve low overall energy consumption, low water consumption, and convenient harvesting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

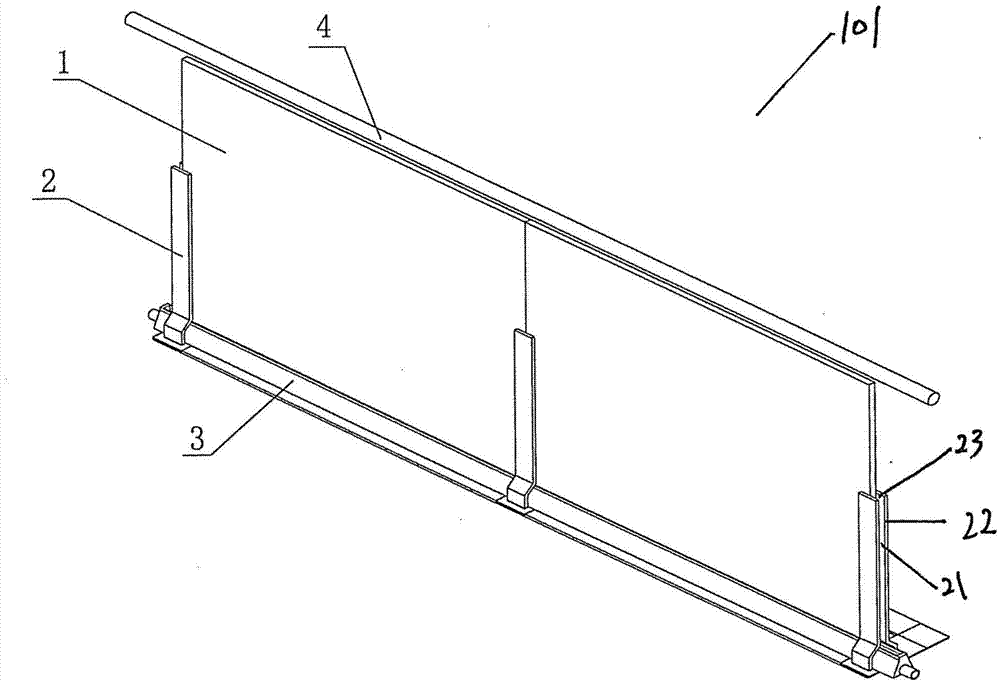

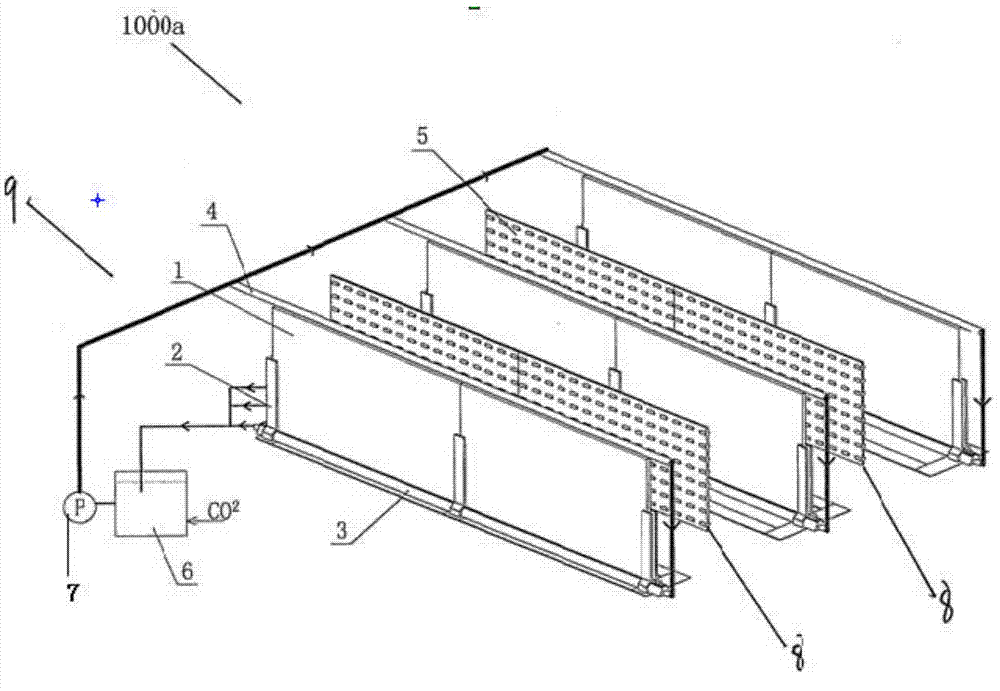

[0081] combine figure 1 and figure 2 Be explained, figure 2 Showing the surface growth type culture system 1000a of the present invention, the surface growth type culture system 1000a may comprise a plurality of such as figure 1 Shown are the culture units 101 , the light source device 8 disposed between the culture units 101 , and the culture solution supply device 9 for supplying the culture solution to the culture units 101 .

[0082] Such as figure 1 and 2 As mentioned above, the fixing device 2 includes opposite fixing components 21 and 22, a hole 23 for fixing the culture plate 1 is formed between the fixing components 21 and 22, and the culture plate 1 can also be taken out from the hole 23 upwards.

[0083] figure 2 A plurality of culture units 101 in the set are arranged parallel to each other and separated by a distance. At least one light source device 8 is arranged between every two culture units 101 . The light source device can be a double-sided light s...

Embodiment 2

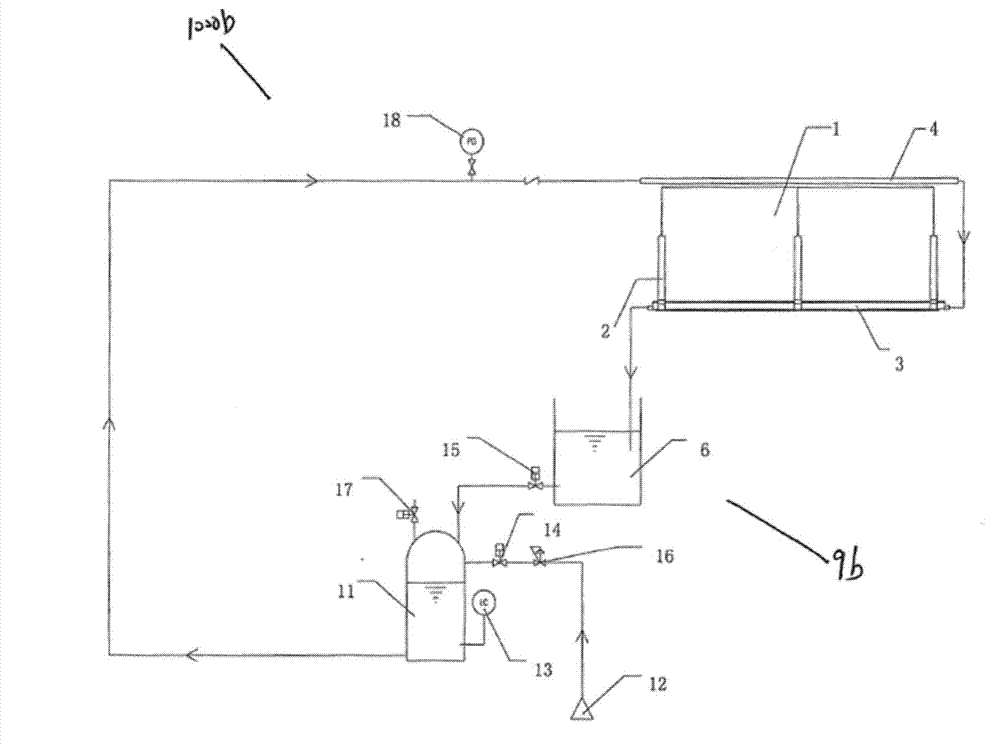

[0088] combine figure 1 and image 3 Another cultivation system 1000b of the present invention is illustrated. image 3 A surface-grown culture system 1000b of the present invention is shown. and figure 2 Similar to the illustrated embodiment, the culture system 1000b may also include one or more figure 1 The culture unit 101. Specifically, the culture system 1000b may include a culture plate 1, a fixing device 2, a culture solution recovery device 3, a liquid supply device 4, a culture solution pool 6, a pressure tank 11, a compressed air source 12, a liquid level gauge 13, and a shut-off valve 14 , Stop valve 15, pressure reducing valve 16, exhaust valve 17, and pressure gauge 18.

[0089] image 3 The surface growth culture system 1000b includes a culture solution circulation device 9b, and the air compression method can be optionally used in the culture solution circulation device 9b. The device used in this air compression method is other optional pressure pump re...

preparation example

[0109] First, material A and material B will be mixed at a mass ratio of A:B of 1:1, said material A being a molecular sieve ZSM-5 with about The mixture is processed at a temperature range of 80 to 100° C. and a normal pressure range, and cooled to form a porous plate. The obtained porous plate has a first pore diameter of about 20 μm.

[0110] Then, to the surface of both sides of the above-mentioned formed perforated plate, apply film-making liquid C (by roller coating, spraying or immersion process), the quality of C is no more than 5% of the above-mentioned formed perforated plate’s total weight, and C is a better choice For the material containing molecular sieve ZSM-5, under the temperature range of 80 to 100°C and normal pressure conditions, C forms an ultra-microporous membrane with a second pore size of 0.9-1.1 μm on the surface of a porous plate. Obtain the culture plate of the present invention ①.

[0111] Alternatively, apply the film-making solution C' to the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com