High-purity, high-crystallinity spherical nickel-cobalt-manganese precursor material and preparation method thereof

A nickel-cobalt-manganese and precursor technology, which is applied to structural parts, electrical components, battery electrodes, etc., can solve the problems of poor nickel-cobalt-manganese co-precipitation, affecting the performance of battery materials, and poor product consistency, and achieving low impurity content. , the effect of high crystallinity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

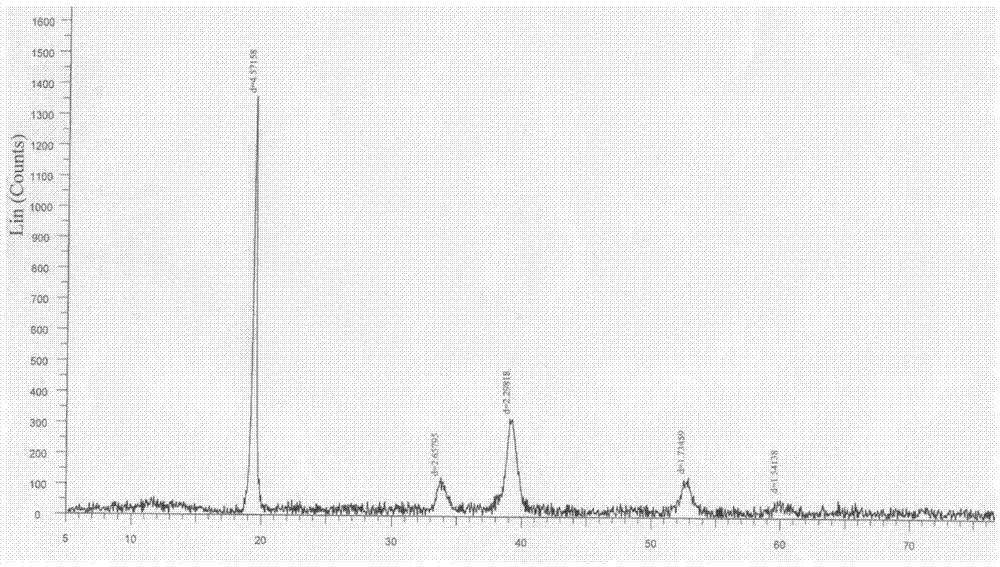

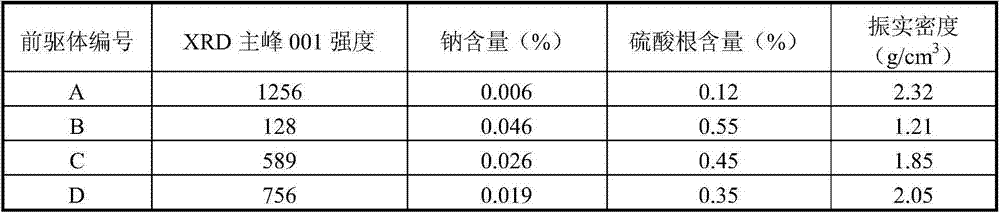

[0031] A high-purity, highly crystalline quasi-spherical nickel-cobalt-manganese precursor material, the chemical molecular formula of the nickel-cobalt-manganese precursor material is Ni 1-x-y co x mn y (OH) 2 , where 0<x<1, 0<y<1; the sodium impurity content in the nickel-cobalt-manganese precursor material is ≤0.012%, the sulfate root impurity content is ≤0.30%, and the nickel-cobalt-manganese precursor material has high crystallinity, XRD characterization Intensity of characteristic peak 001≥1100.

[0032] The preparation method of spherical nickel-cobalt-manganese precursor material of the present invention comprises the following steps:

[0033] (1) Preparation of raw materials: first prepare nickel salt, cobalt salt, and manganese salt to form a mixed salt solution, and the total concentration of the three elements of nickel, cobalt, and manganese in the mixed salt solution is controlled at 80 to 120g / L; Mix uniformly with reducing agent to obtain mixed solution A (...

Embodiment 1

[0041] a kind of like figure 1 , figure 2 The high-purity, highly crystalline quasi-spherical nickel-cobalt-manganese precursor material of the present invention shown in the present invention, the chemical molecular formula of the nickel-cobalt-manganese precursor material is Ni 1-x-y co x mn y (OH) 2 , where 0<x<1, 0<y<1; the sodium impurity content in the nickel-cobalt-manganese precursor material is 0.006%, the sulfate radical content is 0.12%, the nickel-cobalt-manganese precursor material has high crystallinity, and is under XRD characterization The intensity of characteristic peak 001 is 1256.

[0042] The preparation method of the spherical nickel-cobalt-manganese precursor material of this embodiment comprises the following steps:

[0043] (1) Dissolve nickel sulfate, manganese sulfate and cobalt sulfate in water respectively to prepare a mixed salt solution. In the mixed salt solution, the total concentration of the three elements of nickel, cobalt and manganes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com