Sulfuration modification method of xylene isomerization catalyst

A catalyst and isomerization technology, applied in catalyst activation/preparation, physical/chemical process catalyst, isomerization hydrocarbon production, etc., can solve problems such as sulfur poisoning and achieve high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

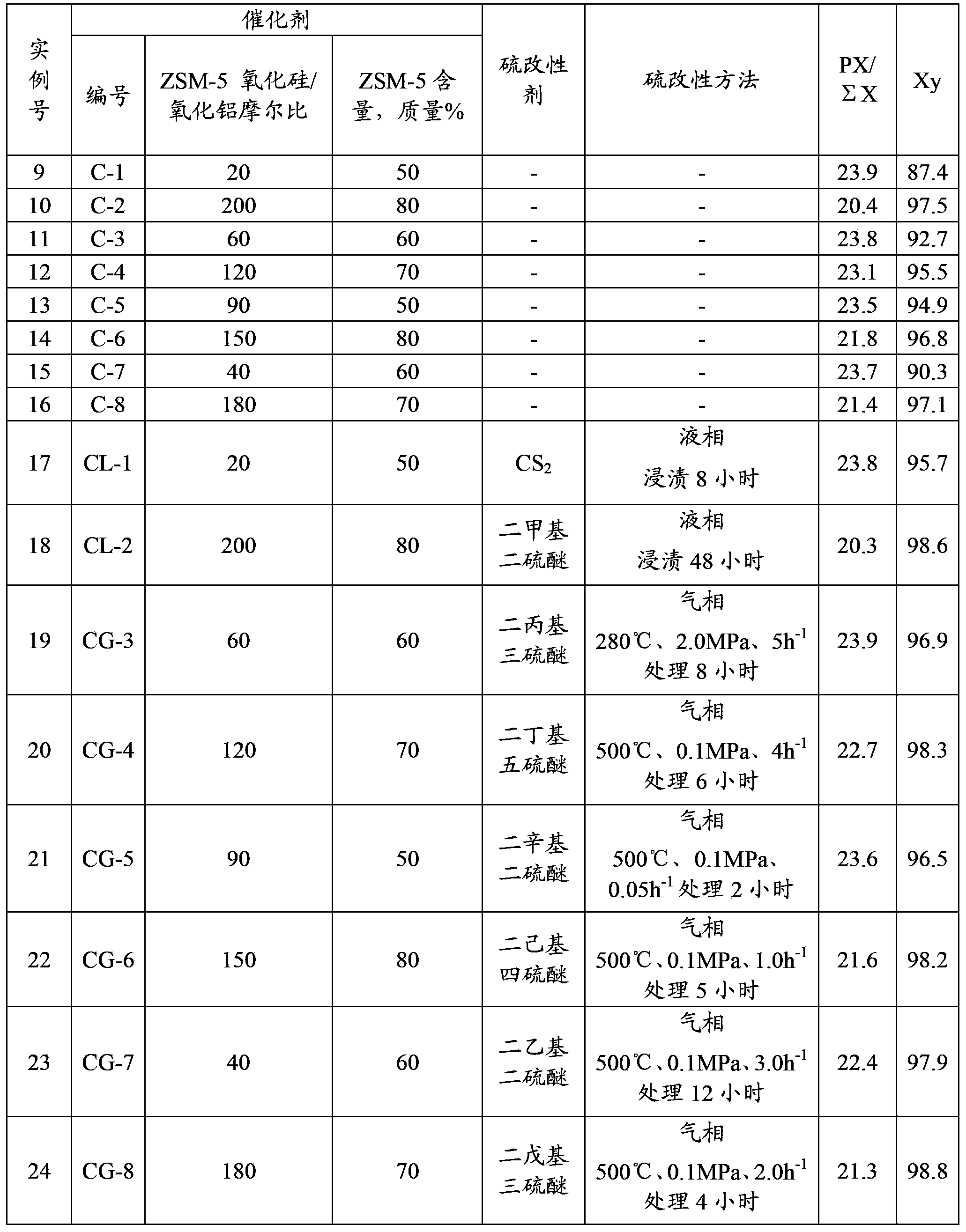

example 1

[0045] The following examples prepare catalysts according to the method of the present invention.

[0046] Take 10 grams of SiO 2 / Al 2 o 3 ZSM-5 molecular sieve powder with a molar ratio of 20 was thoroughly mixed with 10 grams of alumina (Condea company, C1 powder). Add 20 ml of nitric acid aqueous solution with a concentration of 3% by mass, knead, and extrude. Dry the strips at 120°C for 6 hours, cut into pellets, and bake at 550°C for 4 hours. Ion exchange was carried out at 90° C. for 2 hours with 50 ml of aqueous ammonium chloride solution having a concentration of 2% by mass, and the mother liquor was washed until there was no chloride ion in the mother liquor. Immerse in 20 grams of carbon disulfide at 25°C for 8 hours to carry out liquid phase modification. After the impregnation, drain the carbon disulfide, dry at 120°C for 8 hours, and roast in air at 500°C for 2 hours. Then use 20 ml of chloroplatinic acid aqueous solution containing 0.004 g of platinum to im...

example 2

[0048] Prepare catalyst by the method for example 1, difference is to get SiO 2 / Al 2 o 3 16 grams of ZSM-5 molecular sieve with a molar ratio of 200 and 4 grams of alumina were mixed and formed. After ammonium exchange, they were immersed in 40 grams of dimethyl disulfide at 25°C for 48 hours for liquid-phase sulfur modification. After the impregnation, Drain dimethyl disulfide, dry at 120°C for 24 hours, and roast in air at 280°C for 12 hours. Use 20 milliliters of chloroplatinic acid aqueous solution containing 0.1 grams of platinum as the impregnation solution to impregnate the platinum primer, dry, roast and reduce to obtain the catalyst CL-2, which has a platinum content of 0.5% by mass and a sulfur content of 0.5% by mass.

example 3

[0050] Prepare catalyst by the method for example 1, difference is to get SiO 2 / Al 2 o 3 12 grams of ZSM-5 molecular sieves with a molar ratio of 60 and 8 grams of aluminum oxide are mixed and formed, and the catalyst after reduction is carried out gas-phase sulfur modification in hydrogen, and dipropyl trisulfide is passed into hydrogen during gas-phase sulfur modification, so that Hydrogen contains 1 mass% sulfur, at 280°C, 2.0MPa, hydrogen passing through space velocity for 5h -1 Carry out under the condition of 8 hours, obtain catalyst CG-3, and its platinum content is 0.05 mass %, and sulfur content is 0.05 mass %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com