Preparation method for garnet phase nano-powder

A nano-powder and garnet-phase technology is applied in the field of improving the chemical co-precipitation method to synthesize high-sintering activity garnet-phase nano-powder, which can solve the problems of reduced sintering activity and easy agglomeration of garnet-phase nano-powder, and achieves high sintering activity. The effect of sintering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

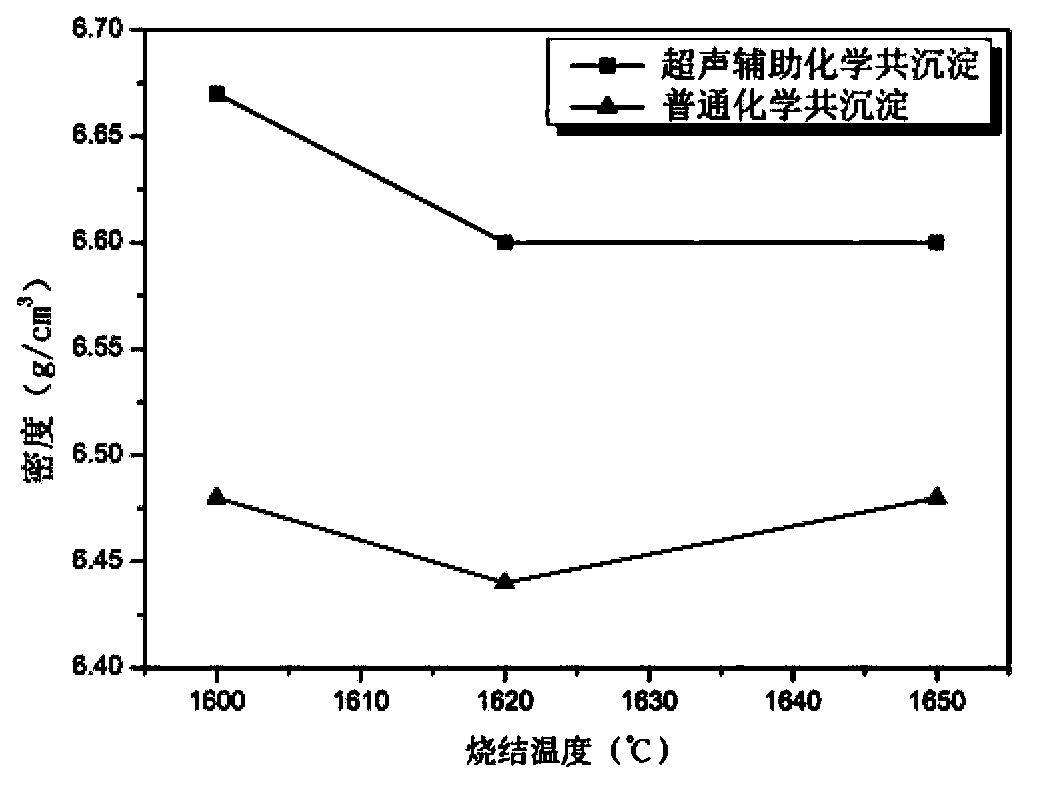

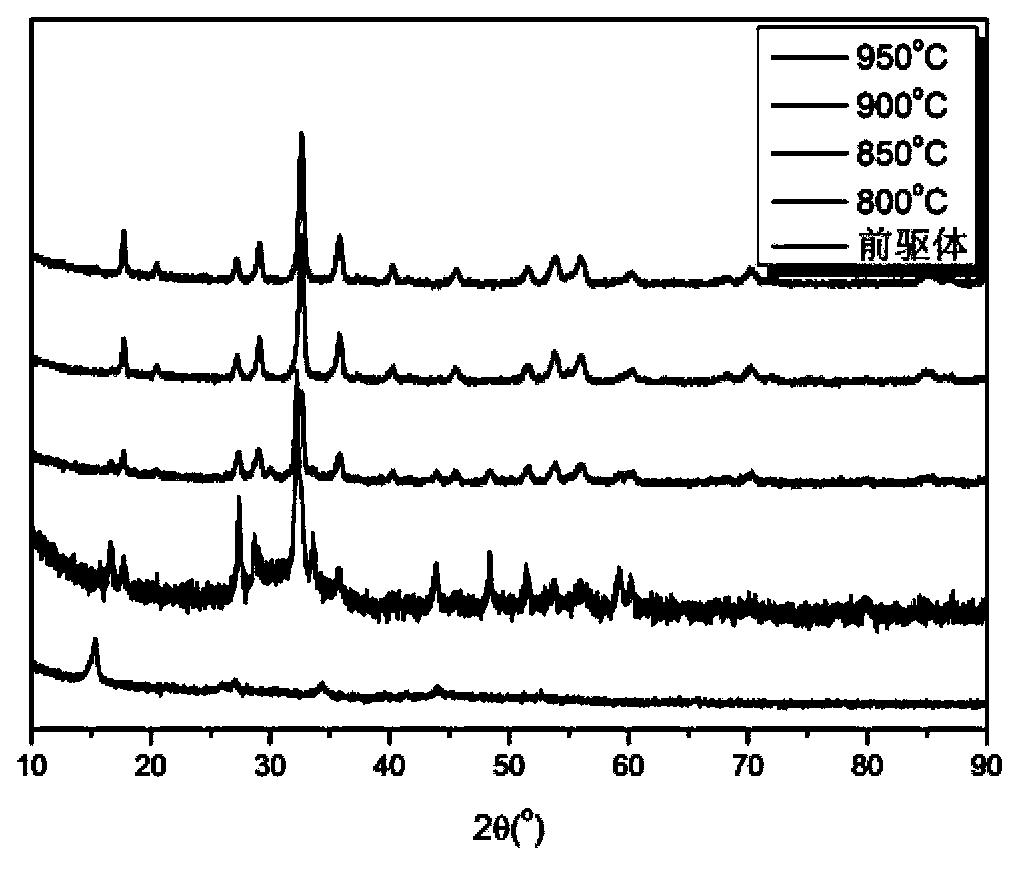

[0038] In this example, the elemental molecular formula of the garnet phase nanopowder is exactly the same as that in Comparative Example 1 above. The preparation method of the powder is basically the same as that in Comparative Example 1 above, the difference is that the chemical co-precipitation process is carried out in a special reaction environment using ultrasonic waves to generate cavitation effects, that is, step (3) is as follows ;

[0039] (3) Place the container holding the precipitant solution B in the ultrasonic pool, and then add the mixed solution A to the precipitant solution B dropwise, so that the dropping process is carried out under ultrasonic vibration conditions, and during the dropping process Accompanied by vigorous mechanical stirring, the droplet velocity of the mixed liquid is 165ml / min, and the ultrasonic power is 200W; after the precipitation is complete, it is suction filtered, washed, dried, ground and sieved to obtain powder C;

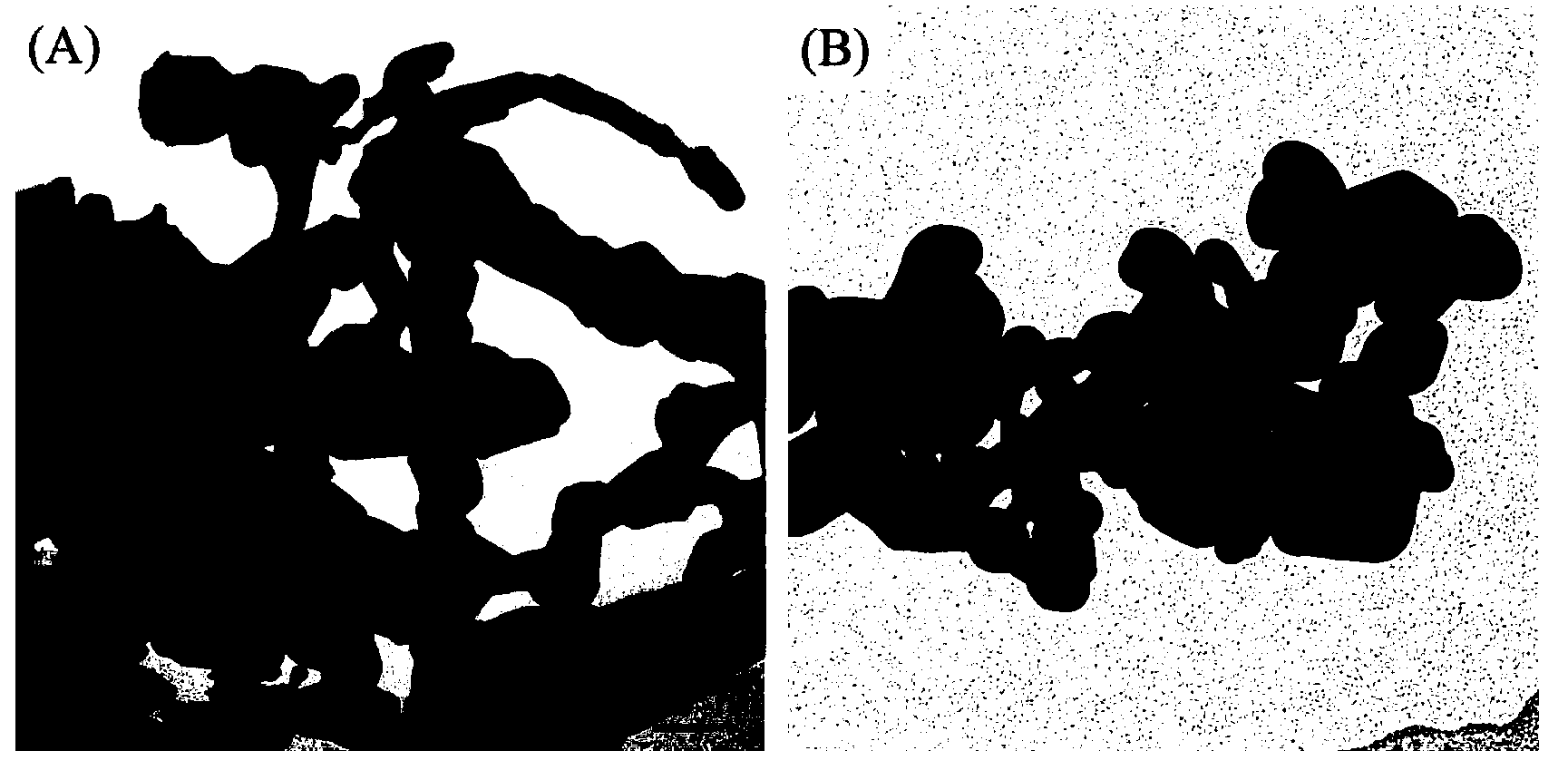

[0040] The mic...

Embodiment 2

[0044] In this example, the elemental molecular formula of the garnet phase nanopowder is Ce 0.015 Gd 2.985 Al 3 Ga 2 o 12 . The preparation method of the powder is as follows:

[0045] (1) Weigh cerium carbonate, gadolinium oxide, gallium oxide, and aluminum sulfate according to the stoichiometric ratio of each element, dissolve them in nitric acid, and make a mixed solution A with a concentration of 1mol / L;

[0046] (2) Select the mixed alkali of ammonia water and ammonium bicarbonate as the precipitant, add deionized water, and make a precipitant solution B with a concentration of 1mol / L, wherein the molar ratio of ammonia water and ammonium bicarbonate is 1:1;

[0047] (3) Place the container holding the precipitant solution B in the ultrasonic pool, and then add the mixed solution A to the precipitant solution B dropwise, so that the dropping process is carried out under ultrasonic vibration conditions, and during the dropping process Accompanied by vigorous mechani...

Embodiment 3

[0050] In this embodiment, the elemental molecular formula of the garnet phase nanopowder is Pr 0.015 Gd 2.985 Al 2 Ga 3 o 12 . The preparation method of the powder is as follows:

[0051] (1) Weigh praseodymium oxide, gadolinium oxide, gallium oxide, and ammonium aluminum sulfate according to the stoichiometric ratio of each element, dissolve them in hydrochloric acid, and make a mixed solution A with a concentration of 0.3mol / L;

[0052] (2) Select the mixed alkali of ammonia water and ammonium bicarbonate as the precipitant, add deionized water, and make a precipitant solution B with a concentration of 2mol / L, wherein the molar ratio of ammonia water and ammonium bicarbonate is 1:4;

[0053] (3) Place the container holding the precipitant solution B in the ultrasonic pool, and then add the mixed solution A to the precipitant solution B dropwise, so that the dropping process is carried out under ultrasonic vibration conditions, and during the dropping process Accompani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com