Nano-scale catalytic metal-ceramic bonding firing-free bitumen-impregnation-free environment-friendly slide plate and preparation method thereof

An environment-friendly, ceramic-combined technology, applied in the field of high-temperature ceramics and refractory materials in the field of inorganic non-metallic materials, can solve the problem of low temperature strength of non-burning skateboards, reduce sensitivity, clean working environment, and improve thermal shock stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

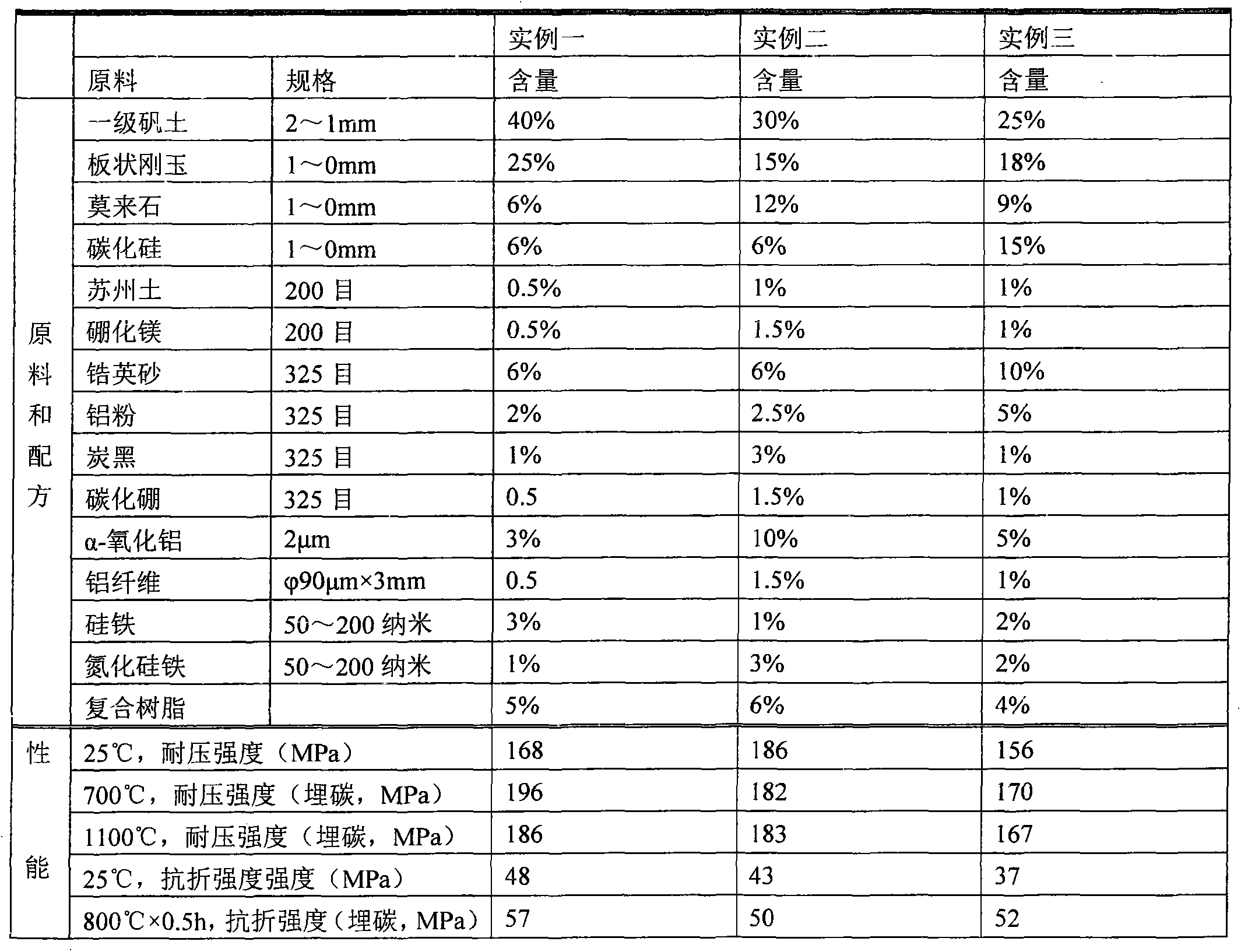

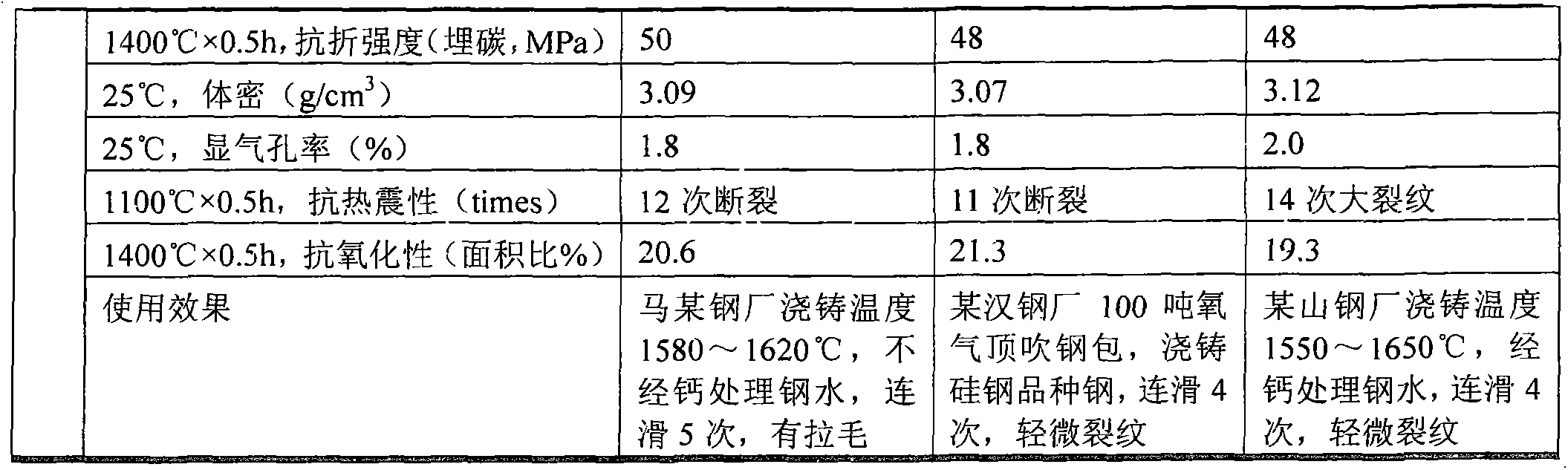

Embodiment 1

[0042] Skateboards are produced according to the following formula and process: (1) 200 mesh Suzhou soil 0.5%, magnesium boride 0.5%, 325 mesh zircon sand 6%, aluminum powder 2%, carbon black 1%, boron carbide 0.5%, 2μm α - The ratio of 3% of alumina micropowder is fine powder and micropowder to be premixed for 20 minutes; (2) Measure the resin according to the ratio of 5% of the composite resin, mix the silicone resin and the phenolic resin in a ratio of 3:1, and Add and account for the mixed solution gross weight 3% polycarboxylate dispersant configuration composite resin binder, then mix in 50 nanometers of catalyzer ferrosilicon nanopowder 3%, silicon nitride nanopowder 1%, and disperse 20 minutes with ultrasonic wave; (3 ) according to the ratio of 40% of first-grade alumina with a particle size of 2-1mm, 25% of platy corundum with a particle size of 1-0mm, 6% of mullite, 6% of silicon carbide, and 0.5% of aluminum fiber, dry-mix for 3 minutes, and add 1 % composite resin...

Embodiment 2

[0048] Skateboards are produced according to the following formula and process: (1) 200 mesh Suzhou soil 1%, magnesium boride 1.5%, 325 mesh zircon sand 6%, aluminum powder 2.5%, carbon black 3%, boron carbide 1.5%, 2μm α - The ratio of 10% of alumina micropowder is fine powder and micropowder to be premixed for 15 minutes; (2) Measure the resin according to the ratio of 6% of the composite resin, mix the silicone resin and the phenolic resin in a ratio of 1:1, and Add and account for the mixed solution gross weight 3% polycarboxylate dispersant configuration composite resin binder, then mix in 200 nanometers of catalyzer ferrosilicon nanopowders, 2% of ferrosilicon nitride nanopowders, and disperse with ultrasonic wave for 40 minutes; (3 ) according to the ratio of 25% of first-grade alumina with a particle size of 2-1mm, 18% of platy corundum with a particle size of 1-0mm, 9% of mullite, 15% of silicon carbide, and 1% of aluminum fiber, dry-mix for 3 minutes, and add 2 % com...

Embodiment 3

[0051] Skateboards are produced according to the following formula and process: (1) 200 mesh Suzhou soil 1%, magnesium boride 1%, 325 mesh zircon sand 10%, aluminum powder 5%, carbon black 1%, boron carbide 1%, 2μm α -Alumina micropowder 5% ratio, fine powder, micropowder are carried out strong premixing for 20 minutes; (2) Measure resin according to the ratio of composite resin 4%, mix organic silicon resin and phenolic resin by the ratio of 2: 1, another Add and account for the mixed solution gross weight 2% polycarboxylate dispersant configuration composite resin binder, then mix in 100 nanometers of catalyzer ferrosilicon nanopowder 1%, silicon nitride nanopowder 3%, and disperse with ultrasonic wave for 30 minutes; (3 ) according to the ratio of 30% of first grade bauxite with a particle size of 2-1mm, 15% of platy corundum with a particle size of 1-0mm, 12% of mullite, 6% of silicon carbide, and 1.5% of aluminum fiber, dry mix for 2 minutes, and add 3 % composite resin b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com