A kind of slow and controlled release fertilizer and its production method

A technology of slow and controlled release fertilizers and production methods, which is applied to nitrogen fertilizers, organic fertilizers, matrix fertilizers, etc. It can solve the problems of difficult to achieve harmless products, bottlenecks in product promotion, and nutrient loss, etc., to increase fertilizer and water retention performance , Promote the construction of ecological civilization and increase the content of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

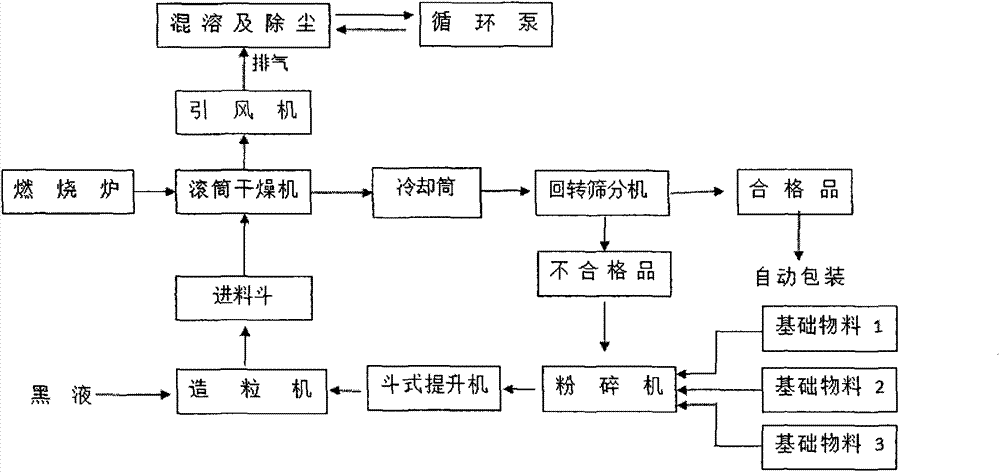

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the production of organic slow and controlled release potassium fertilizer

[0029] 1,200kg of peat is crushed into a powder of 60-200 meshes, the water content is kept at 8-15%, mixed evenly, and put into a disc or drum granulator. Then the pulping raffinate with a Baume degree of 30-32 and a temperature of 60-100°C is controlled by a flowmeter to 0.5-0.6m 3 / h, spray atomization at a pressure of 0.15-0.5MPa, and spray the surface of the humic acid rotating in the disc. The particles are gradually enlarged by rotation. Dry, cool and sieve to obtain particles with diameters of 1mm≤d≤2.5mm and 2.5≤d≤5mm, and pack them as products. According to NY525-2012 Organic Fertilizer Standard, the product has been determined to contain K 2 O ≥ 8%, organic matter ≥ 45%, pH 6.1.

Embodiment 2

[0030] Embodiment 2: the production of high-potassium organic slow-release fertilizer

[0031] 1,000kg of peat is crushed into a powder of 60-200 meshes, the water content is kept at 8-15%, mixed evenly, and put into a disc or drum granulator. Then the pulping raffinate liquid with a Baume degree of 30-32 and a temperature of 80°C is controlled by a flow meter to flow out 1m 3 / h, spray atomization at a pressure of 0.15-0.5MPa, and spray the surface of the humic acid rotating in the disc. The particles are gradually enlarged by rotation. Dry, cool and sieve into particles with diameters of 1mm≤d≤2.5mm and 2.5≤d≤5mm, and pack them as products. According to NY525-2012 Organic Fertilizer Standard, the product has been determined to contain K 2 O ≥ 14%, organic matter ≥ 45%, pH 8.3.

Embodiment 3

[0032] Example 3: Ternary Compound Fertilizer

[0033] 200kg of urea, 100kg of monoammonium phosphate, containing K 2 700kg of O≥8% high-potassium organic fertilizer is crushed and made into a powder of 60-200 mesh, fully mixed, stirred evenly, granulated by common methods, dried, and packaged to obtain an organic-inorganic compound fertilizer. According to GB18877-2002 National Standard for Organic-Inorganic Compound Fertilizer, it has been determined that the product contains N≥10%, P 2 o 5 ≥6%, K 2 O≥6%, organic matter≥25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com