Potato slag comprehensive utilization processing method for combined production of starch and meal fiber

A technology of potato residue and dietary fiber, applied in the field of joint production of starch and dietary fiber, can solve problems such as increasing pollution sources, save water consumption, realize microcrystallization, good physical properties and physiological activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

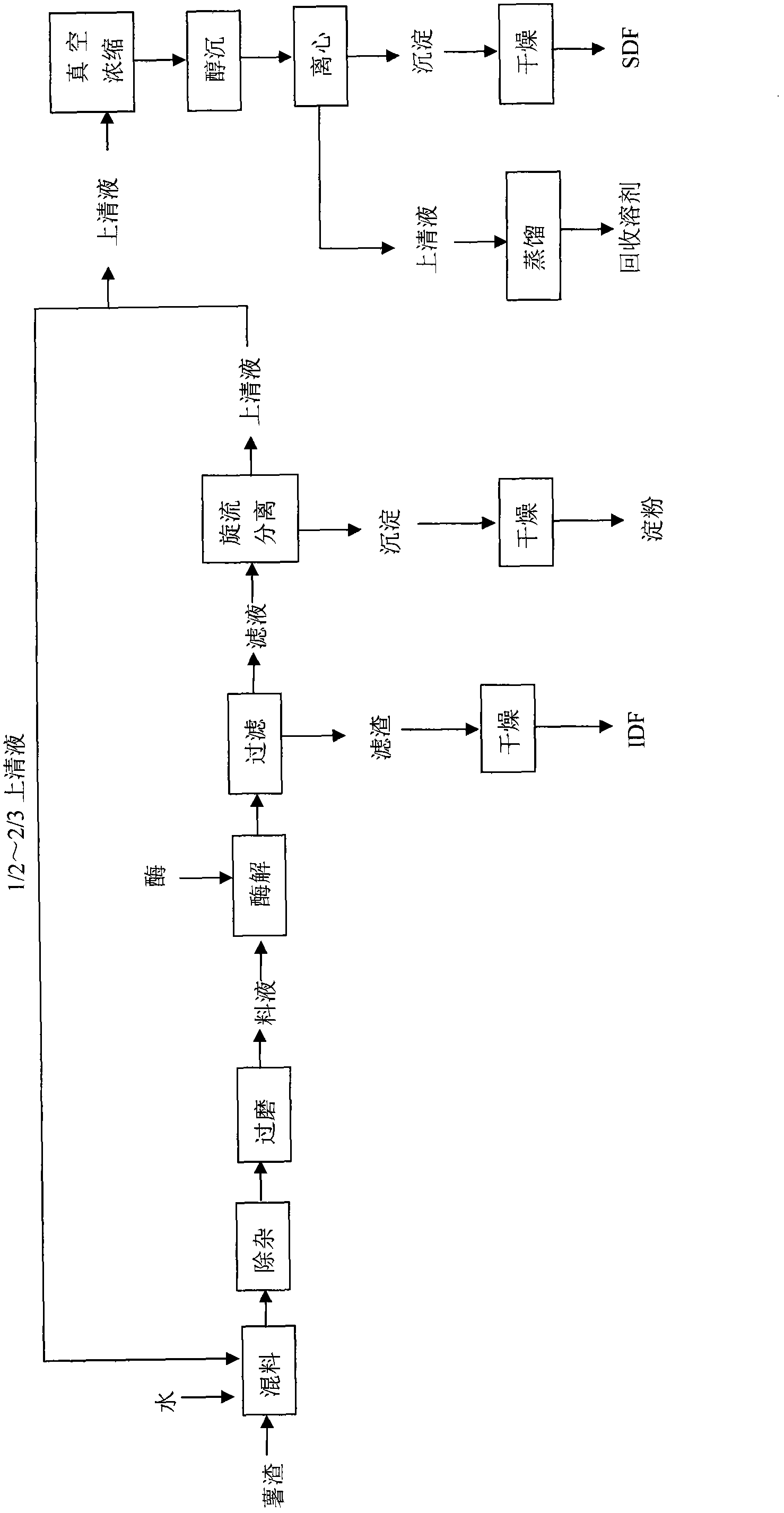

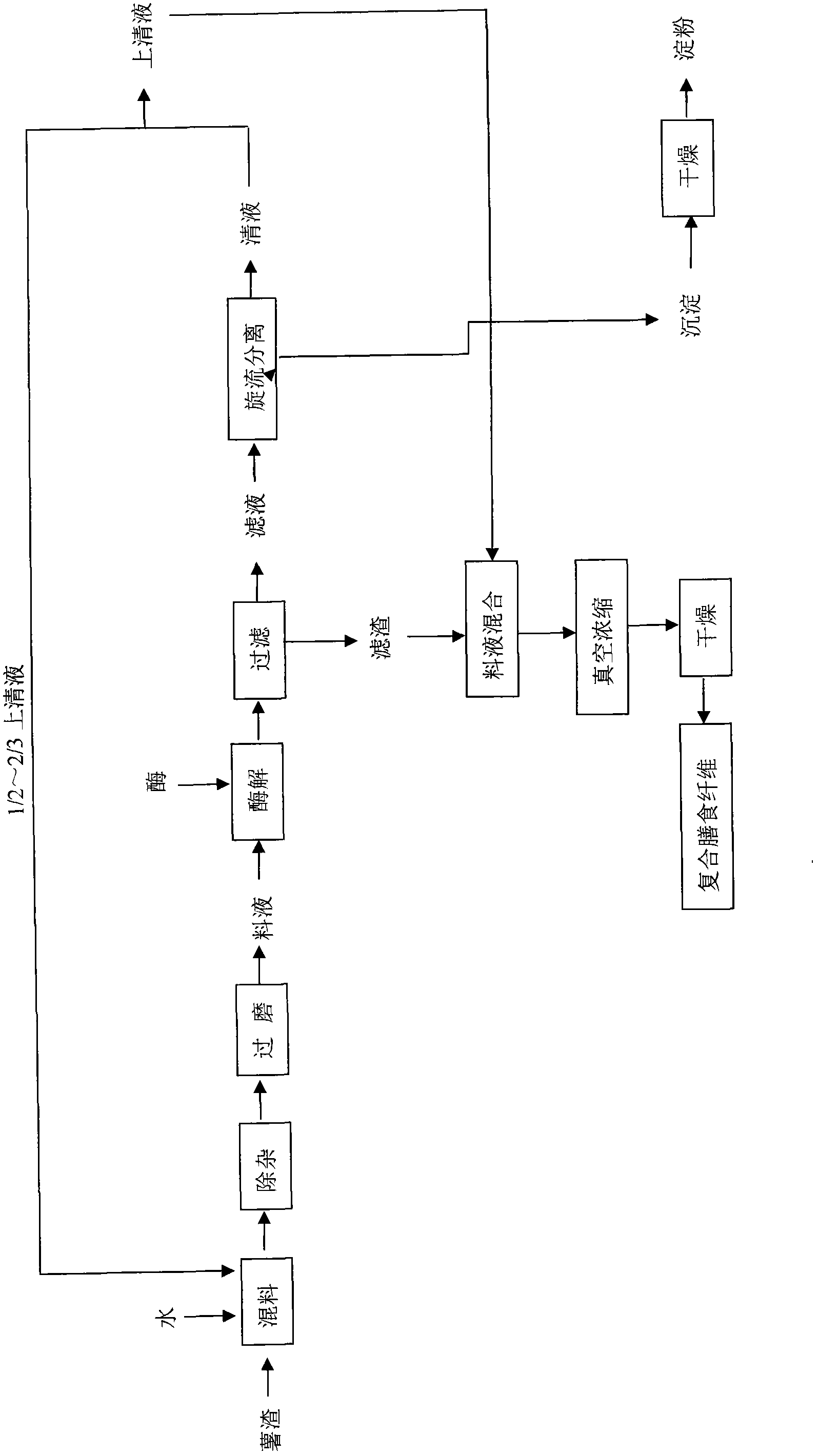

Method used

Image

Examples

Embodiment 1

[0023] (1) In the mixing tank, 50kg of potato residues are mixed with water evenly, the mass ratio of water and raw materials is 3: 1, and the resulting feed liquid is pumped into a filter and a cyclone desander to remove impurities such as sand grains;

[0024] (2) Treat the feed liquid with a colloid mill for 2 minutes after removing impurities to obtain a homogeneous feed liquid;

[0025] (3) Adjusting the pH of the homogeneous feed solution to 4.5, adding a mixture consisting of cellulase, pectinase, acid protease, xylanase, and mannanase in a mass ratio of 5:2:1:1:1 Compound enzyme, the enzyme concentration is 2g / L, carry out enzymatic conversion at 45 ℃ for 1h, filter through a filter press, and obtain the filtrate after enzymolysis and the filter cake after enzymolysis respectively (that is, filter residue, obtained after filtering by a filter press) Filter residue can also be referred to as filter cake, the same below).

[0026] (4) The filtrate after the enzymolysis ...

Embodiment 2

[0030] (1) In the mixing tank, 25kg of potato residues are mixed with water evenly, the mass ratio of water and raw materials is 4: 1, and the resulting feed liquid is pumped into a filter and a cyclone desander to remove impurities such as sand grains;

[0031] (2) Treat the feed liquid with a colloid mill for 2 minutes after removing impurities to obtain a homogeneous feed liquid;

[0032] (3) Adjust the pH of the homogeneous feed solution to 4.5, add cellulase, pectinase, acid protease, xylanase, and mannanase in a mass ratio of 8:3:1:2:2 The complex enzyme, the enzyme concentration is 0.5g / L, the enzymatic conversion is carried out at 50°C for 1h, and the filtrate and filter cake are respectively obtained after being filtered through a filter press;

[0033] (4) separating the filtrate obtained in step (3) through a cyclone to obtain a precipitate and a supernatant;

[0034] (5) Return 1 / 2 of the supernatant obtained in step (4) to the mixing tank of step (1), add 50L of ...

Embodiment 3

[0038] (1) In the mixing tank, 50kg of potato residues are mixed with water evenly, the mass ratio of water and raw materials is 3: 1, and the resulting feed liquid is pumped into a filter and a cyclone desander to remove impurities such as sand grains;

[0039] (2) Treat the feed liquid with a colloid mill for 2 minutes after removing impurities to obtain a homogeneous feed liquid;

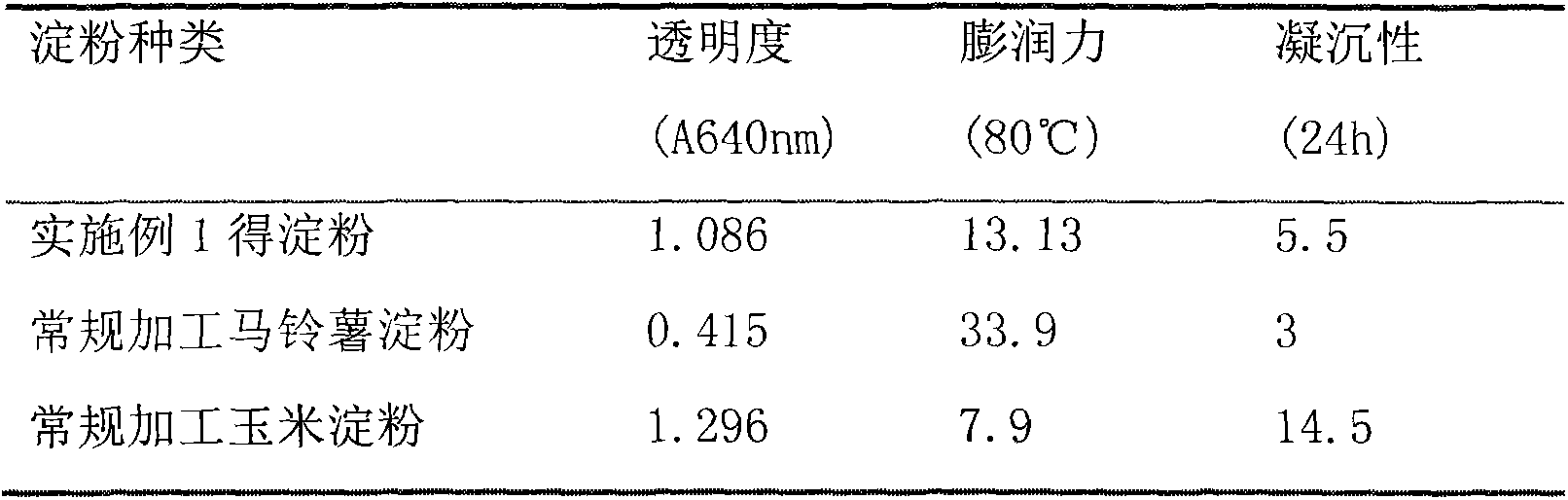

[0040] (3) adjusting the pH of the homogeneous material liquid obtained in step (2) to be 4.5, adding cellulase, pectinase, acid protease, xylanase, mannanase in a mass ratio of 9:3:1:2 : the composite enzyme of 2 compositions, enzyme concentration is 1.5g / L, carries out enzymatic conversion 2h at 45 ℃, obtains filtrate and filter cake respectively after press filtration by filter press; (4) step (3) gained filtrate is passed through Cyclone separation to obtain precipitate and supernatant, the resulting precipitate was dried by a vacuum drum dryer to obtain 1.1kg of starch;

[0041] (5) Concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com