Room-temperature self-curing inorganic phosphate anti-corrosion paint as well as preparing method and use method of paint

A technology of inorganic phosphates and anti-corrosion coatings, applied in anti-corrosion coatings, coatings and other directions, can solve the problem that the application has not been widely promoted, and achieve the effects of delaying curing time, saving costs and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

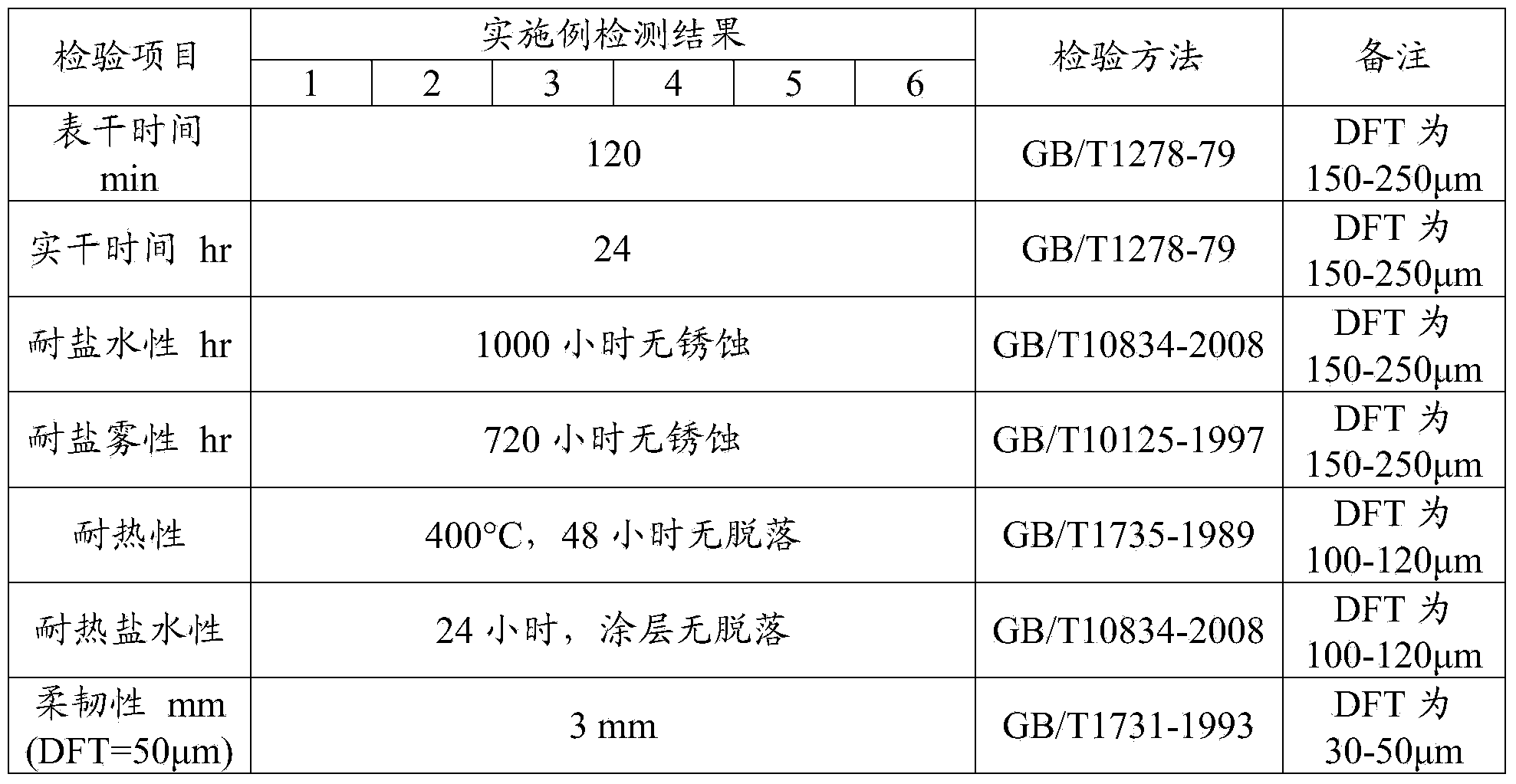

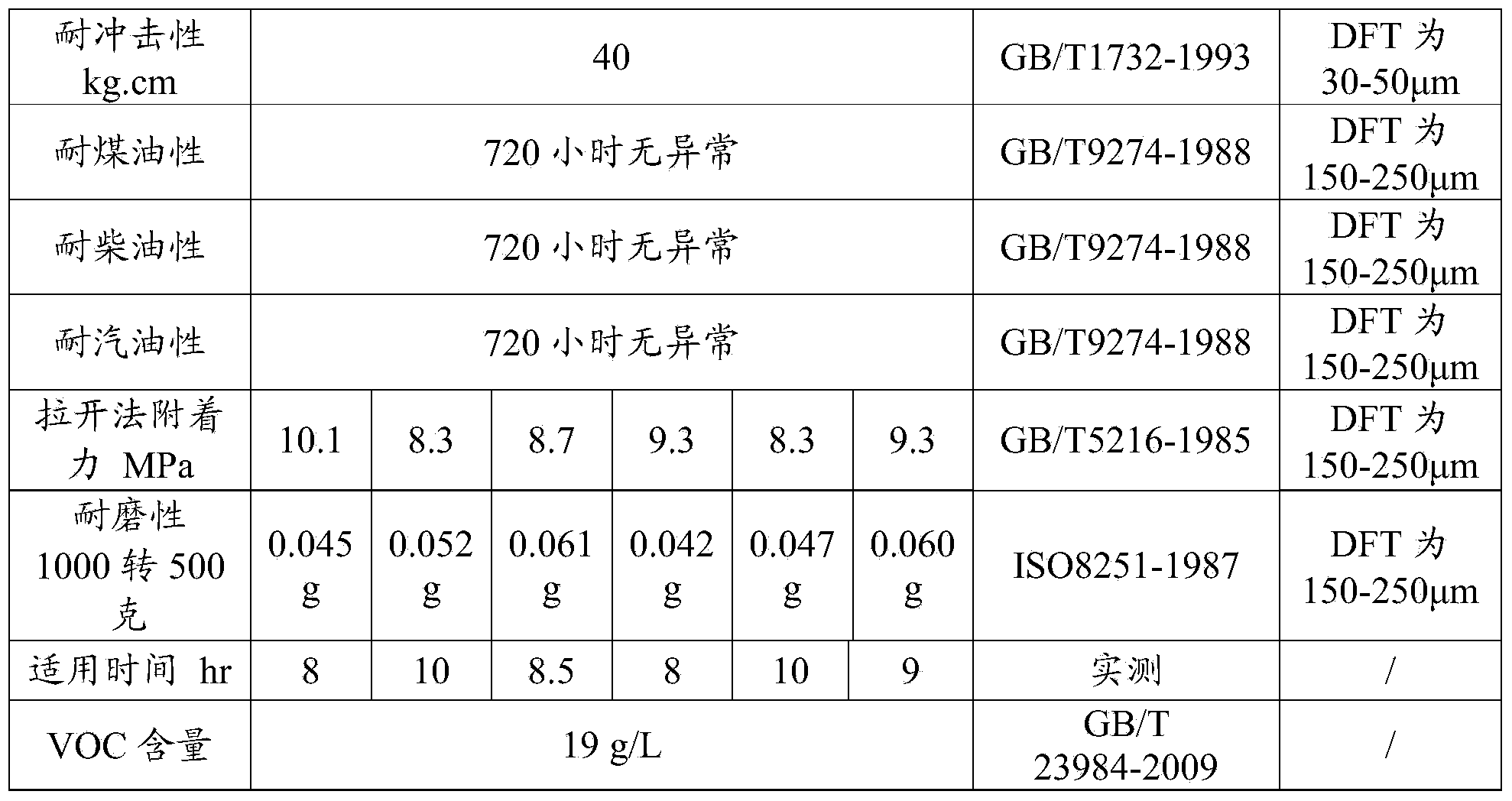

Examples

preparation example Construction

[0097] The present invention also provides the preparation method of above-mentioned normal temperature self-curing inorganic phosphate anticorrosion coating, comprising the following steps:

[0098] mixing a metal compound with a phosphoric acid solution and heating to obtain a phosphate adhesive, the metal compound including metal oxide and / or metal hydroxide;

[0099] Mix the phosphate adhesive, pigments and fillers, functional additives and deionized water to obtain component A;

[0100] The basic metal oxide is coated with inorganic nanoparticles to obtain a curing agent, the curing agent has a core-shell structure, the shell in the core-shell structure is inorganic nanoparticles, and the core in the core-shell structure is alkaline metal oxide thing;

[0101] Mix the curing agent with pigments and fillers, industrial solid waste, functional additives and deionized water to obtain component B;

[0102] The A component and the B component are mixed to obtain a normal tem...

Embodiment 1

[0122] According to the ratio of Al:P molar ratio of 1.4:3, aluminum hydroxide powder was added to a phosphoric acid solution with a mass concentration of 50% and mixed, heated and stirred in an oil bath at 150°C, and reacted for 0.5 hours to obtain an aqueous solution of phosphate adhesive; Add 24 parts of titanium dioxide, 0.5 parts of phosphate chromium-free corrosion inhibitor, 0.5 parts of iron phosphate, and 15 parts of deionized water to 60 parts of phosphate adhesive aqueous solution, mix and stir for 15 minutes to obtain coating A component.

[0123] Magnesium oxide particles are coated with silica nanoparticles by sol-gel method:

[0124] Add 3g of MgO powder into the mixed solvent (100mL of ethanol + 30mL of deionized water + 2mL of ammonia water), and ultrasonically shake for 1h to fully disperse it to obtain the MgO dispersion;

[0125] Slowly add a mixture of 30 mL tetraethyl orthosilicate (TEOS) and 50 mL absolute ethanol dropwise to the MgO dispersion under mag...

Embodiment 2

[0134] According to the ratio of Al:P molar ratio of 1.0:3, aluminum hydroxide powder is added to a phosphoric acid solution with a mass concentration of 50% and mixed, heated and stirred in an oil bath at 180° C., and reacted for 1 hour to obtain an aqueous phosphate adhesive solution; Add 32 parts of iron oxide red, 1.5 parts of polyphosphate chromium-free corrosion inhibitor, 1.5 parts of iron phosphate and 15 parts of deionized water to 50 parts of phosphate adhesive aqueous solution, mix and stir for 15 minutes to obtain coating A component;

[0135] Zinc oxide particles were coated with silica nanoparticles by sol-gel method:

[0136] Take 3g of ZnO powder and add it to the mixed solvent (100mL ethanol + 30mL deionized water + 2mL ammonia water), and ultrasonically oscillate for 1h to fully disperse it to obtain a zinc oxide dispersion;

[0137] Slowly add a mixture of 30mL TEOS and 50mL absolute ethanol dropwise to the obtained zinc oxide dispersion under magnetic stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com