A kind of amorphous nanometer silica powder and preparation method thereof

A nano-silicon dioxide, amorphous technology, applied in the direction of silicon dioxide, silicon oxide, nanotechnology, etc., can solve the problems of large environmental pollution, many organic waste solvents, etc., to achieve low reaction temperature, high silicon and oxygen content, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare tetramethylammonium hydroxide into a 25% aqueous solution (weight concentration), then mix according to the weight ratio of octamethylcyclotetrasiloxane: tetramethylammonium hydroxide = 100:0.1, and then rapidly heat up to 90°C , heat preservation reaction 1h; then dropwise add 30 parts of vinyltrimethoxysilane, react for 2.5h, then add 5 parts of 50% ethanol aqueous solution, then add 0.1 part of tetramethylammonium hydroxide aqueous solution, and then add 5 Part of distilled water was reacted for 1 hour to start vacuum distillation, and at the same time, the temperature was raised to 130°C, the pressure was -700mmHg, and the solution was turned into a gel after vacuum distillation for 10 minutes;

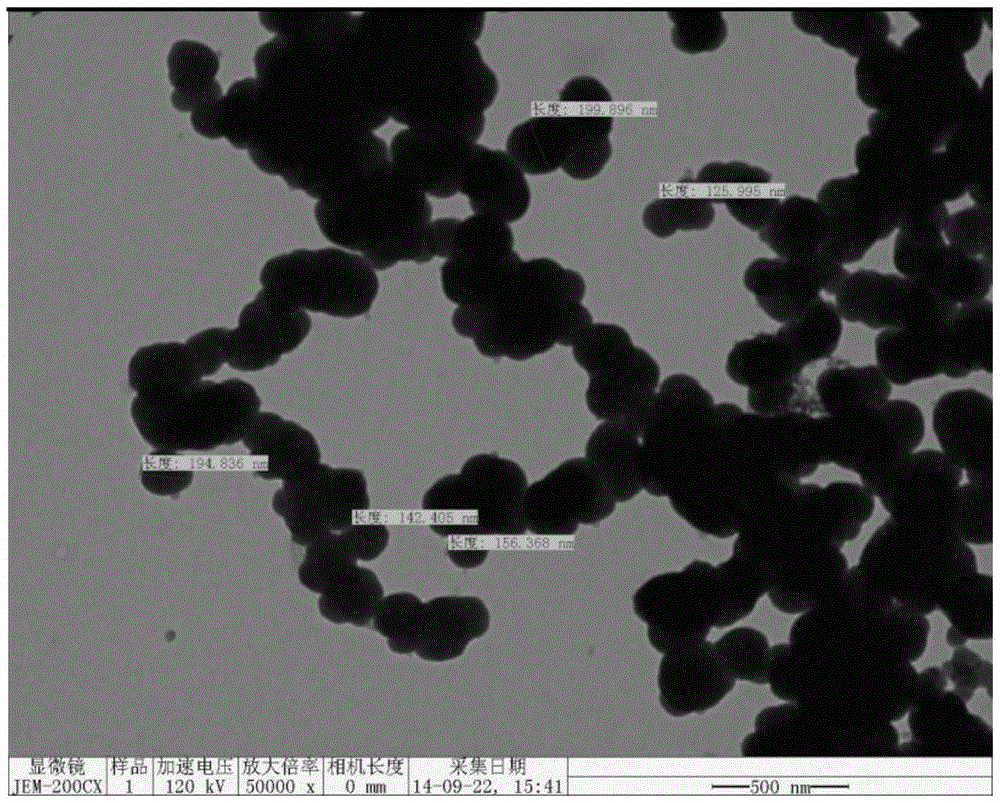

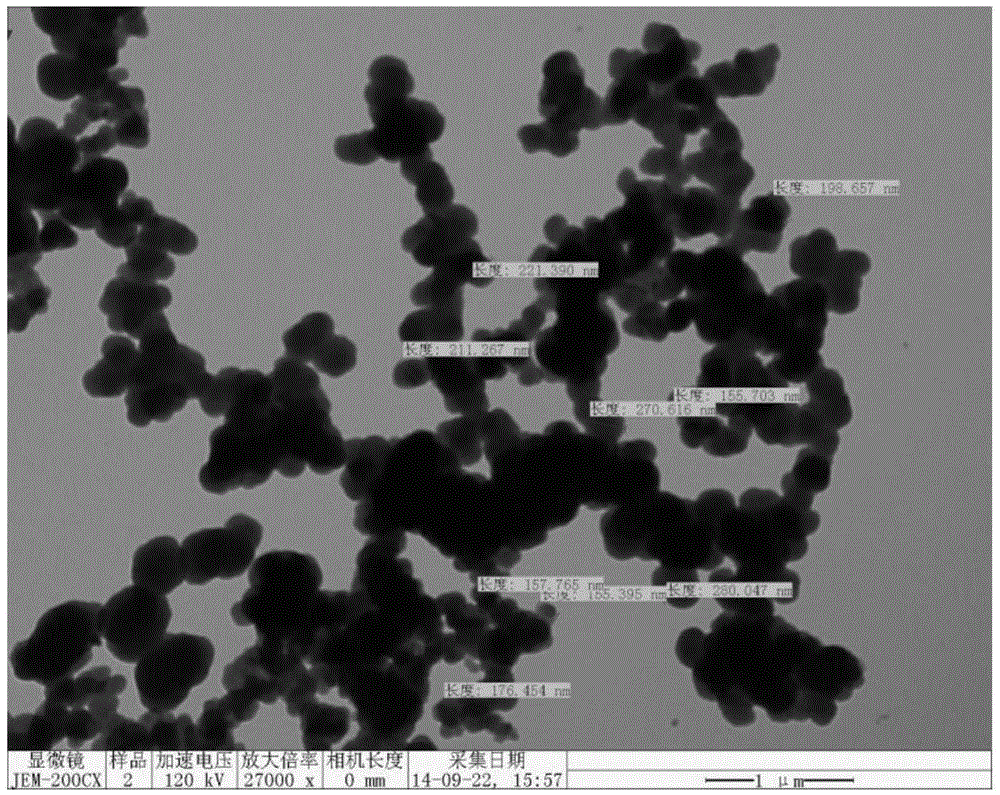

[0032] Dry the wet gel at room temperature for 1 hour to obtain dry xerogel, which can be simply ground into a fine powder; calcinate the xerogel at 350°C for 1.5 hours to obtain white amorphous nano-silica micropowder with a particle size of 70-200nm.

Embodiment 2

[0034] Tetramethylammonium hydroxide was formulated into a 25% aqueous solution (weight concentration), then mixed according to the weight ratio of decamethylcyclopentasiloxane:tetramethylammonium hydroxide=100:0.5, and then rapidly heated to 85°C, Insulation reaction for 1.5h; then 30 parts of vinyltrimethoxysilane was added dropwise, reacted for 2.5h, then 5 parts of 50% ethanol aqueous solution was added, and 0.1 part of tetramethylammonium hydroxide aqueous solution was added, and then 15 parts of Parts of distilled water reacted for 1 hour and began to distill under reduced pressure. At the same time, the temperature was raised to 130°C, the pressure was -700mmHg, and the solution was distilled under reduced pressure for 40 minutes, and the solution became a gel;

[0035] Dry the wet gel at room temperature for 1 hour to obtain dry xerogel, which can be simply ground into a fine powder; calcinate the xerogel at 350°C for 1.5 hours to obtain white amorphous nano-silica micr...

Embodiment 3

[0037]Prepare tetramethylammonium hydroxide into a 25% aqueous solution (weight concentration), then mix according to the weight ratio of dodecamethylcyclohexasiloxane: tetramethylammonium hydroxide = 100:0.8, and then rapidly heat up to 80°C , keep warm for 1 hour; then add 40 parts of vinyltrimethoxysilane dropwise, react for 2 hours, then add 6 parts of 50% ethanol aqueous solution, then add 0.5 parts of tetramethylammonium hydroxide aqueous solution, and then add 8 parts The distilled water was reacted for 1 hour to start vacuum distillation, and at the same time, the temperature was raised to 130°C, the pressure was -700mmHg, and the vacuum distillation was 30 minutes, and the solution became a gel;

[0038] Dry the wet gel at room temperature for 1 hour to obtain dry xerogel, which can be simply ground into a fine powder; calcinate the xerogel at 300°C for 2 hours to obtain white amorphous nano-silica powder with a particle size of 70 ~200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com