Plasticizer production wastewater treatment method

A technology for the production of wastewater and treatment methods, which is applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of large investment in treatment facilities and unsatisfactory results, and achieve sludge reduction The effect of treatment and disposal costs, less sludge production, and simple operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Aiming at the characteristics of non-continuous and uniform discharge of wastewater and large changes in water quality, an adjustment pool is set up to balance the water quantity and quality, and acid is added here to adjust the pH to 6.0-7.0, and the residence time is 24h; according to the biological nutritional balance BOD5: N: P=100: The ratio of 5:1, potassium dihydrogen phosphate and urea are appropriately added to the wastewater; in order to control the sulfate content of wastewater and meet the basic requirements of subsequent biochemical water treatment, it is necessary to mix domestic sewage and tap water before treatment to make sulfate The concentration is lower than 3000 mg / L, and the COD concentration is lower than 15000 mg / L; the wastewater enters the anaerobic treatment tank with filler from the distribution tank, the residence time is 72h, and the treatment load is 5kgCOD / m 3 .d; The biofilm oxidation tank is divided into a zone and a zone two, the first zo...

Embodiment 2

[0022] Embodiment 2: Treatment effect

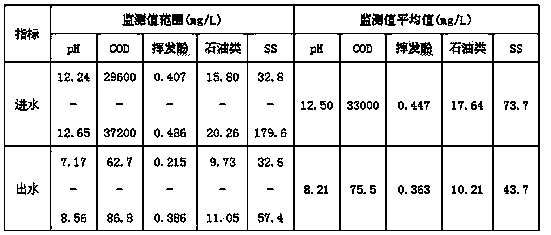

[0023] The plasticizer production wastewater treatment method of the present invention is used to treat plasticizer production wastewater from a plasticizer production plant, and the treatment effect is shown in Table-1.

[0024] Table-1 Treatment effect

[0025]

[0026] It can be seen from Table 1 that in the treatment method of the present invention, the COD removal rate is 97.72%-99.96%, the volatile phenol removal rate is 9.09%-28.89%, and the pollutant emission concentration reaches the first-level emission standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com