Subcritical hydrothermal treatment-based efficient recycling treatment process for sludge

A subcritical water and treatment process technology, applied in the field of solid waste recycling, can solve the problems of complexity, reduced sludge anaerobic digestion efficiency, low dissolution and hydrolysis rate, etc., and achieves less solid residue, fast reaction rate, and residence time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

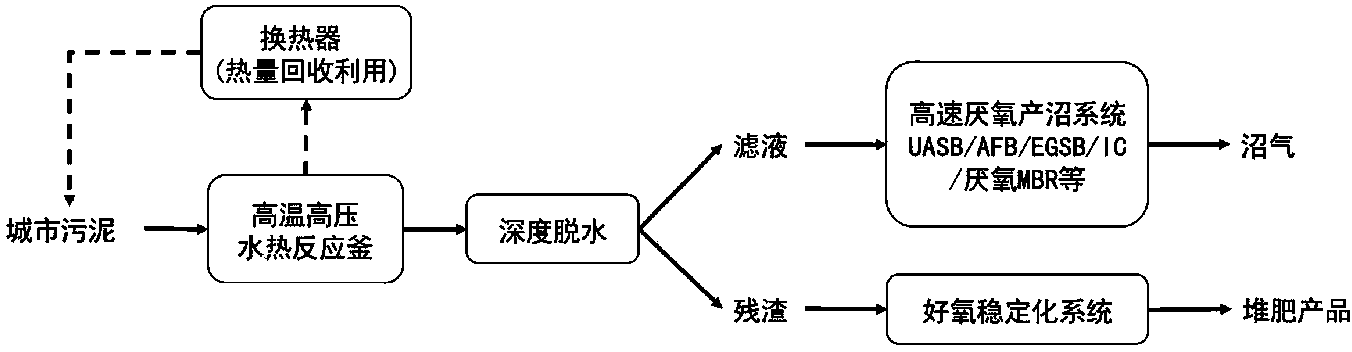

Embodiment 1

[0023] The dewatered sludge of a sewage treatment plant has a measured solid content of 10%. Put 50Kg of the sludge in the sludge storage tank into the inner tank of a hydrothermal reactor with an effective volume of 75L. The set temperature is 200°C and the pressure is 1.6MPa, after reaching the set temperature, maintain it for 30 minutes, recover the water vapor and use it to preheat the sludge in the sludge storage tank. It is measured that the solid content of the sludge after hydrothermal modification is reduced to 8%, and it is obtained after dehydration by plate and frame filtration. The filtrate is 46kg, and the mud cake is 4kg. The filtrate enters the UASB anaerobic digestion water storage tank for subsequent biogas recovery, and the mud cakes produced in multiple batches are jointly treated with aerobic composting.

Embodiment 2

[0025] The dewatered sludge of a sewage treatment plant has a measured solid content of 25%. 50kg of sludge is semi-continuously entered into a subcritical hydrothermal reactor with a temperature of 300°C and a pressure of 8.6MPa through a high-pressure pump to reach the design level. After maintaining the temperature for 10 minutes, the water vapor is recovered and used to preheat the sludge in the mud storage tank. It is measured that the solid content of the sludge after hydrothermal modification is reduced to 15%. 10kg, the reaction material enters the dehydration system after multi-stage decompression cooling, the dehydration filtrate enters the water inlet storage tank of the anaerobic MBR system for subsequent biogas recovery, and the dehydration residue enters aerobic composting treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com