Preparation method of fly ash modified waste plastic composite material

A technology of waste plastics and composite materials, which is applied in the field of preparation of fly ash modified waste plastic composite materials, can solve the problems of increasing the production cost of modified composite materials, physical injury of operators, cumbersome processing process, etc., and achieves a good market Competition and use prospects, simple and easy-to-operate methods, and the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Directly pass the fly ash industrial waste slag of the power plant through a sieve, and collect the fly ash whose particle size is above 200 mesh for subsequent use;

[0029] (2) Mix waste plastics, light stabilizers, lubricants, binders, glass fibers, and fly ash in a weight ratio of 60:0.001:3:10:12:150 to obtain a mixture;

[0030] (3) Adjust the temperature of the mill to 170° C., and melt and blend the mixture in step (2) for 25 minutes to obtain a fly ash-modified waste plastic composite material.

[0031] Among them, high-density polyethylene is selected for waste plastics, bis(2.2.6.6-tetramethyl-4-piperidinyl) sebacate is selected for light stabilizer, polyethylene wax is selected for lubricant, polyamide resin is selected for binder, glass The fiber is alkali-free chopped strand glass fiber.

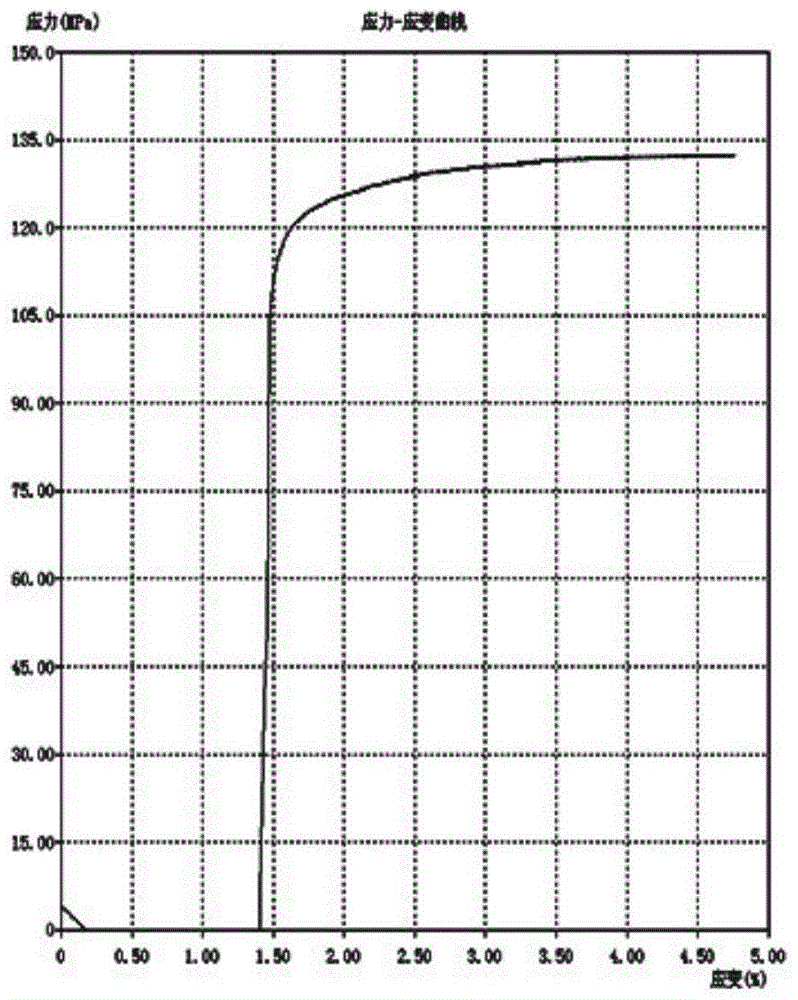

[0032] Adjust the temperature of the flat vulcanizer to 200°C, and press the produced fly ash modified waste plastic composite material into tablets for 5 minutes t...

Embodiment 2

[0035] (1) Directly pass the fly ash industrial waste slag of the power plant through a sieve, and collect the fly ash whose particle size is above 200 mesh for subsequent use;

[0036] (2) Mix waste plastics, light stabilizers, lubricants, binders, glass fibers, and fly ash in a weight ratio of 60:0.002:5:12:15:160 to obtain a mixture;

[0037] (3) Adjust the temperature of the mill to 190° C., and melt and blend the mixture in step (2) for 35 minutes to obtain a fly ash-modified waste plastic composite material.

[0038] Among them, waste plastics should be mixed with low-density polyethylene and polypropylene at a mass ratio of 1:1, bis(1.2.2.6.6-pentamethyl-4-piperidinyl) sebacate should be selected as light stabilizer, and polystyrene should be selected as lubricant. Ethylene wax, stearic acid and butyl stearate are mixed in a mass ratio of 1:2:5, the binder is polyamide resin, and the glass fiber is alkali-free chopped glass fiber.

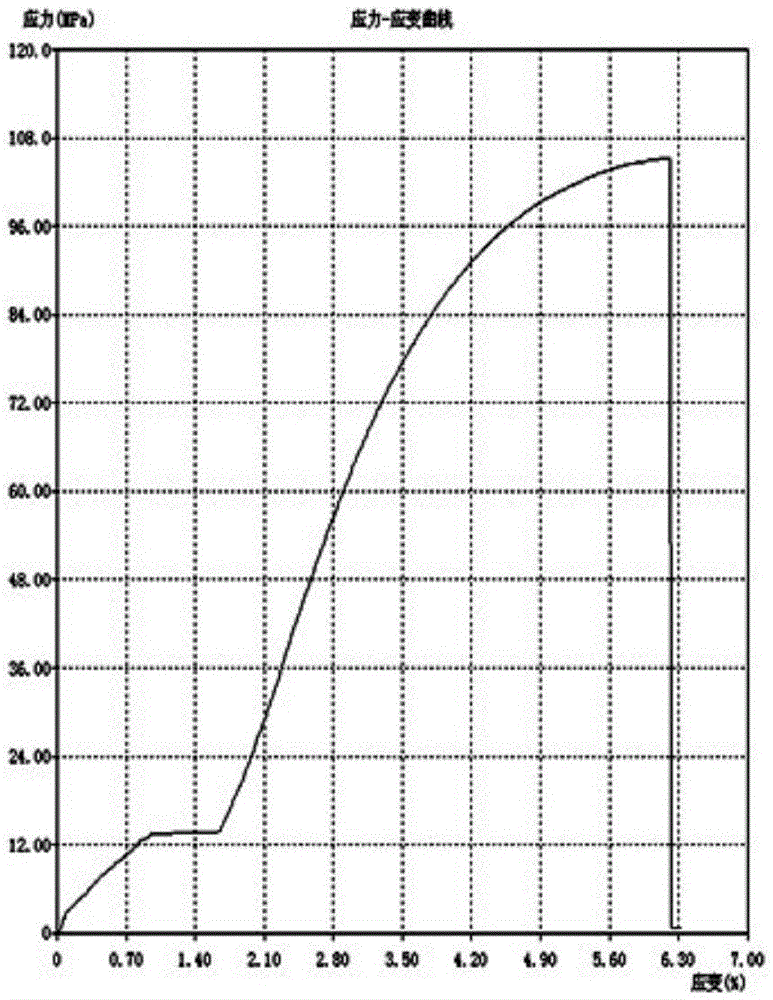

[0039] Using the method of Example 1...

Embodiment 3

[0041] (1) Directly pass the fly ash industrial waste slag of the power plant through a sieve, and collect the fly ash whose particle size is above 200 mesh for subsequent use;

[0042] (2) Mix waste plastics, light stabilizers, lubricants, binders, glass fibers, and fly ash in a weight ratio of 60:0.001:8:10:13:160 to obtain a mixture;

[0043] (3) Adjust the temperature of the mill to 210° C., and melt and blend the mixture in step (2) for 40 minutes to obtain a fly ash-modified waste plastic composite material.

[0044] Among them, waste plastics are mixed with high-density polyethylene and low-density polyethylene at a mass ratio of 3:5, and the light stabilizer is 1-methyl-8-(1.2.2.6.6-pentamethyl-4-piperidinyl)decane The diacid ester, the lubricant selection butyl stearate and ethylene bis stearamide are mixed in a mass ratio of 5:3, the binder is a polyamide resin, and the glass fiber is an alkali-free chopped glass fiber.

[0045] Using the method of Example 1 to meas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com