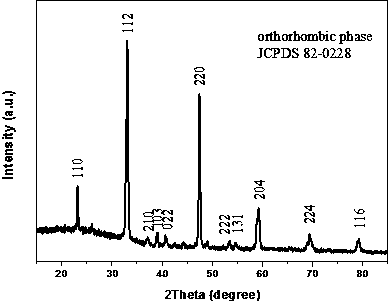

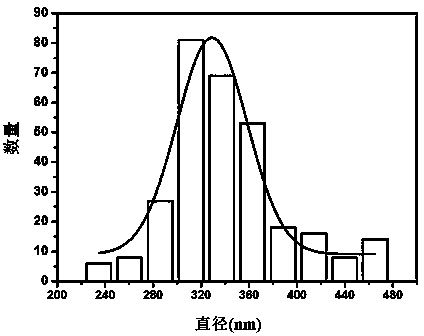

Preparation method of one-dimensional hollow porous structure calcium titanate nanofiber

A technology of nanofibers and porous structures, applied in the manufacture of hollow filaments, preparation of spinning solutions, artificial filaments made of inorganic materials, etc., to achieve good biocompatibility, easy control, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The method of the present invention will be described in further detail below in conjunction with the examples.

[0025] 1) Weigh 0.8169g of butyl titanate and 1.0087g of citric acid and dissolve them in 9ml of ethanol;

[0026] 2) After stirring and dissolving, add 0.5668g of calcium nitrate to the mixed solution of butyl titanate and citric acid prepared in step 1);

[0027] 3) Under slow stirring, add 3ml of dimethylformamide solution dropwise to the mixed solution of butyl titanate, citric acid and calcium nitrate prepared in step 2);

[0028] 4) Under slow stirring, add 0.1512g of F127 nonionic surfactant to the mixed solution prepared in step 3);

[0029] 5) In the state of slow stirring, add 0.39g of polyvinylpyrrolidone to the mixed solution prepared in step 4), and stir for 4 hours to obtain a stable light yellow transparent sol;

[0030] 6) Put the sol prepared in step 5) into the syringe of the electrospinning device, and collect one-dimensional calcium tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com