A kind of high-purity battery grade manganese source and preparation method thereof

A technology of battery grade and manganese source, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor operating environment, long cycle, low cost, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

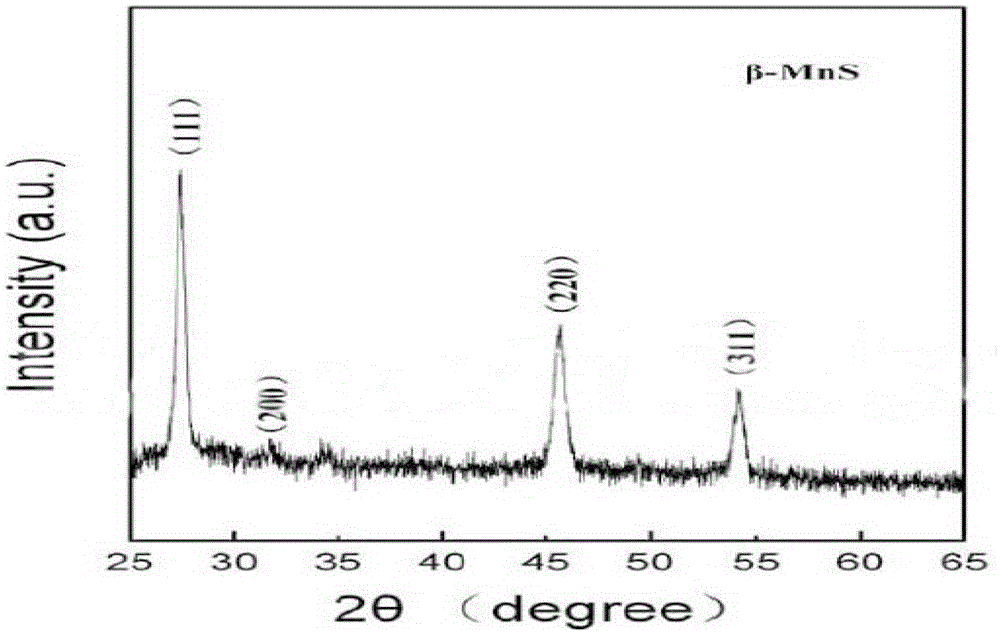

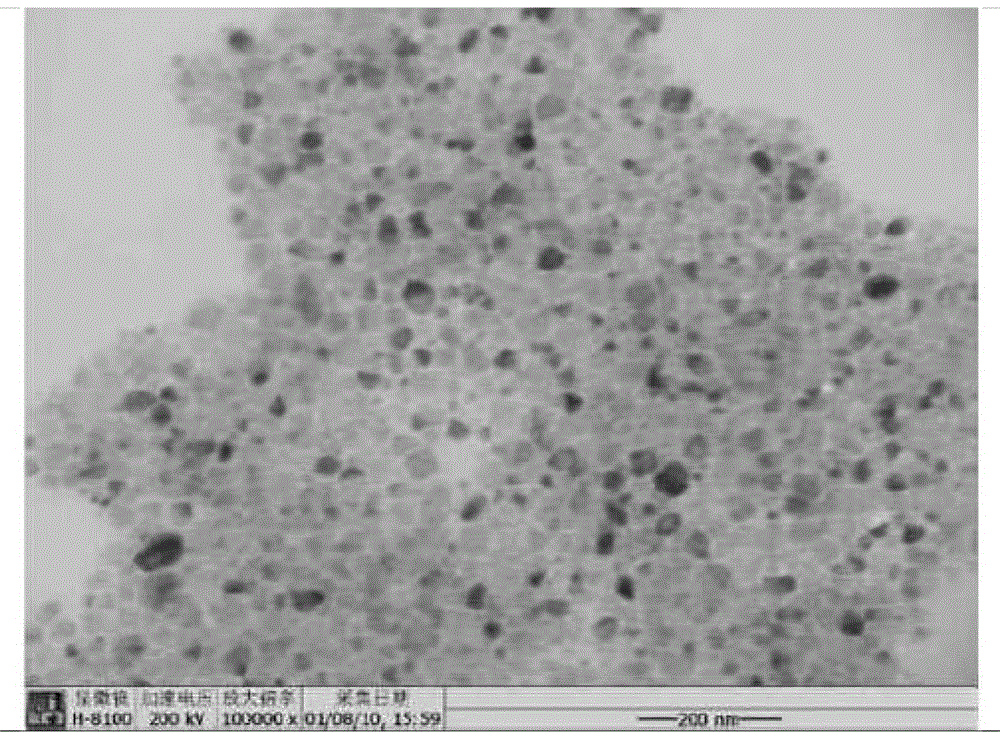

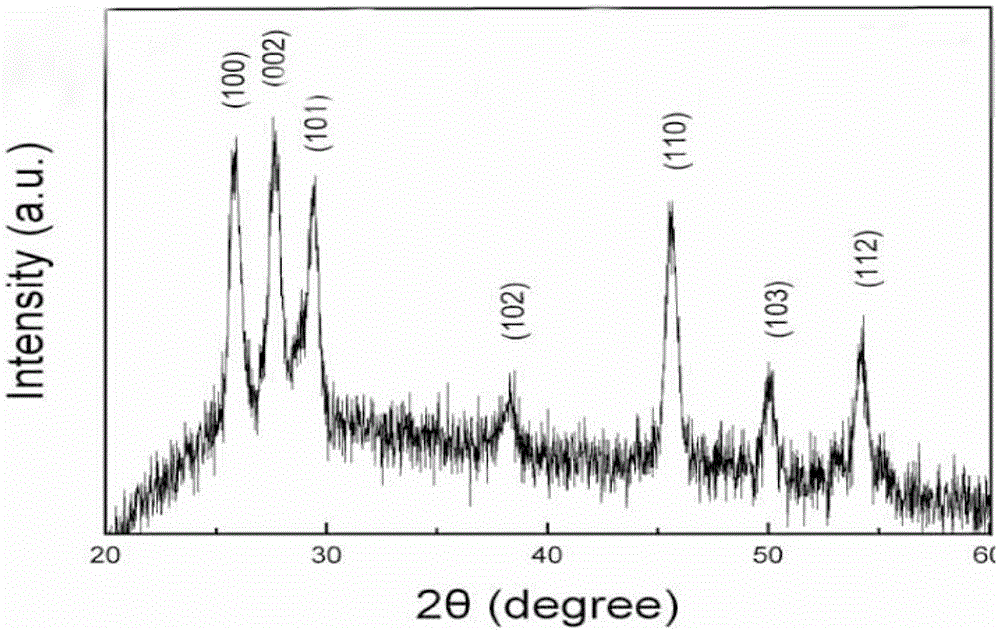

Image

Examples

Embodiment 1

[0035] (1) 3000KG of manganese carbonate ore powder with a total manganese content of 12%, add 1500KG30% industrial hydrochloric acid and 500KG water for acid hydrolysis reaction, and the terminal pH value is controlled at 4.0;

[0036] (2) plate and frame filtration, obtain manganese chloride acid solution;

[0037](3) Add an appropriate amount of industrial grade sodium sulfide crystals, adjust the pH value to 5.5, and keep the temperature at 75°C, react for 120 minutes, and filter to obtain the primary manganese salt solution;

[0038] (4) prepare 25% sodium sulfide solution, stand-by;

[0039] (5) 1500KG of the primary manganese salt solution obtained in step (3) is pumped into the reactor, the stirring is started, and the temperature rises to 45° C.; the sodium sulfide solution prepared in step (4) is slowly added until the pH is stable at 8.5, and the If the manganese element is not detected, the manganese precipitation on the surface is complete; the temperature is rai...

Embodiment 2

[0050] (1) Electrolytic metal manganese 500KG, add 1800KG50% dilute sulfuric acid to carry out acidolysis reaction, the terminal pH value is controlled at 3.0;

[0051] (2) plate and frame filtration, obtain manganese sulfate acid hydrolysis solution;

[0052] (3) prepare 25% sodium sulfide solution, stand-by;

[0053] (4) Add an appropriate amount of industrial-grade 25% sodium sulfide solution, adjust the pH value to 5.0, and keep the temperature at 68° C., react for 120 minutes, and filter to obtain the primary manganese salt solution;

[0054] (5) Pump 2200KG of the primary manganese salt solution obtained in step (3) into the reactor, start stirring, and the temperature rises to 50° C.; slowly add the sodium sulfide solution prepared in step (3) until the pH is stable at 7.0; Rise to 80°C and keep it, continue to react for 4 hours, press filter to obtain manganese sulfide filter cake;

[0055] (6) The filter cake is fully washed three times with pure water at 60° C. to ...

Embodiment 3

[0065] (1) Industrial grade manganese sulfate 1500KG, add 1500KG pure water and heat up properly to fully dissolve;

[0066] (2) plate and frame filtration, obtain manganese sulfate solution;

[0067] (3) Add an appropriate amount of industrial grade sodium sulfide crystals, adjust the pH value to 5.3, and keep the temperature at 55°C, react for 120 minutes, and filter to obtain the primary manganese salt solution;

[0068] (4) prepare 25% sodium sulfide solution, stand-by;

[0069] (5) Pump 2500KG of the primary manganese salt solution obtained in step (3) into the reactor, start stirring, and the temperature rises to 55°C; slowly add the sodium sulfide solution prepared in step (4), until the pH is stable at 6.8; the temperature rises to Keep at 65°C, continue to react for 4 hours, press filter to obtain manganese sulfide filter cake;

[0070] (6) The filter cake is fully washed three times with pure water at 60°C to obtain a high-purity battery-grade manganese source-mang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com