Treatment method for smelting waste water containing sulfuric acid and heavy metal

A treatment method and technology for heavy metals, applied in metallurgical wastewater treatment, neutralized water/sewage treatment, multi-stage water treatment, etc., can solve problems such as difficult to achieve successfully, and achieve lower treatment costs, less sludge, and less pollution to the environment. the effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

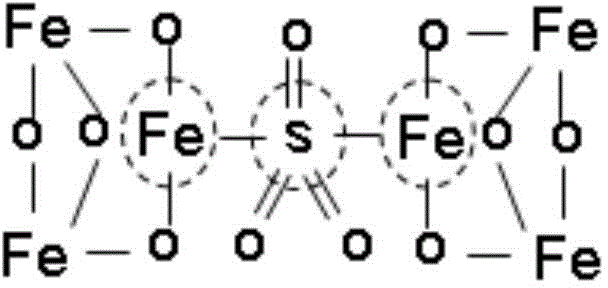

Method used

Image

Examples

Embodiment 1

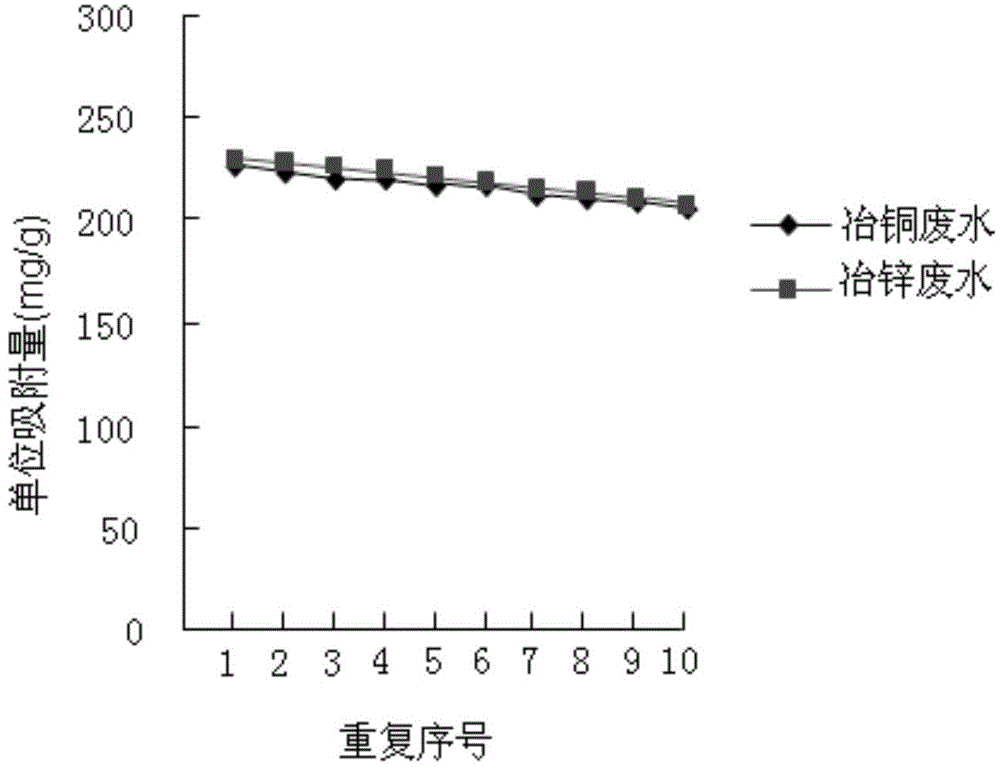

[0032] Embodiment one: use MMP adsorbent to process sulfuric acid and heavy metal smelting wastewater: (1) source of wastewater: copper smelting and zinc smelting wastewater of a certain smelter in Yunnan; experimental method: prepare 2 2-liter beakers, add 1500 ml of Copper smelting or zinc smelting wastewater, and then add MMP adsorbent respectively, the amount added is the ratio of solid content of adsorbent to sulfuric acid content 3:1. Stir for 5 minutes, check the pH, if the pH does not reach 5.5, continue to add the adsorbent until the pH reaches 5.5. Then use a suction filter bottle to filter it. The adsorbent cake and filtrate were collected separately. When collecting the adsorbent filter cake, use 15 ml of tap water to wash as much of the adsorbent particles remaining on the filter paper as possible and pour it into the adsorbent collection. The filtrate was sampled and tested for pH, sulfate, arsenate, and heavy metals such as copper, zinc, and cadmium. The resul...

Embodiment 2

[0035] Embodiment two: prepare 2 2 liters of beakers, get 1200 milliliters in the beakers respectively from two kinds of waste water filtrates collected in the experiment of embodiment one, be its pH with milk of lime of 5% with calcium hydroxide concentration respectively Adjust to 9, fully stir for 5 minutes, then add a small amount of polyacrylamide (PAM) to a concentration of 5ppm, filter with an ultrafiltration bottle and collect the filtrate, and then take samples from the filtrate to test, pH, sulfuric acid root, arsenate, and heavy metals such as copper, zinc, and cadmium. The results are shown in Table 2.

[0036] Table 2 shows the changes in the contents of sulfuric acid, arsenic acid and heavy metals in wastewater after chemical coagulation and precipitation on the basis of adsorption.

[0037]

Embodiment 3

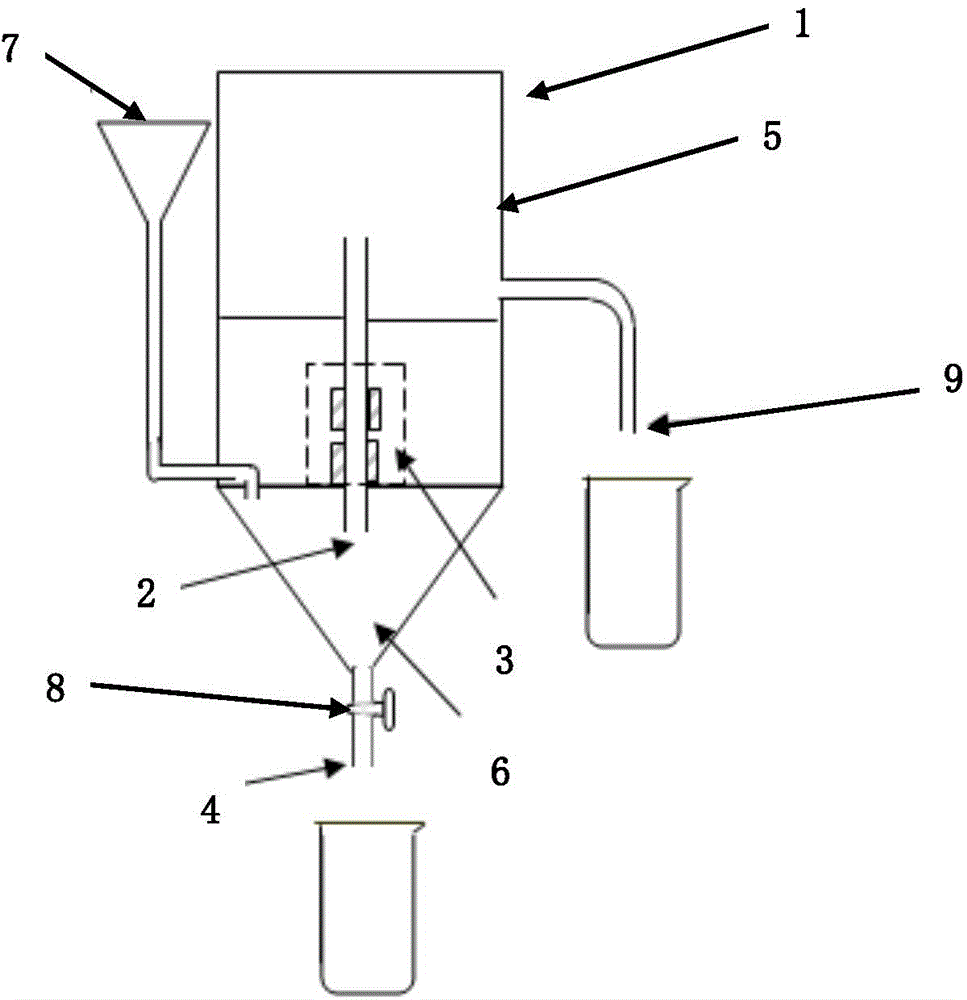

[0038] Embodiment three: prepare 2 beakers of 1000 milliliters, get 1000 milliliters in the beaker respectively from the filtrate of two kinds of waste waters that collect in the experiment of embodiment two, by the ratio of 1:1000, the adsorption that content is 20% The agent was added to 2 beakers and stirred for 2 minutes, then added to such as figure 1 A simulated setup of the heavy metal purifier is shown. Collect clean water from the clean water outlet and take samples to test the pH, sulfate, arsenate, and heavy metals such as copper, zinc, and cadmium. The results are shown in Table 3.

[0039] Table 3 is the change of sulfuric acid, arsenic acid and heavy metal content in wastewater after heavy metal purification treatment on the basis of adsorption and coagulation precipitation.

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com