Organosilane crosslinked polyethylene wood-plastic composite material and preparation method thereof

A wood-plastic composite material and silane crosslinking technology, which is applied in the field of wood-plastic composite material and its preparation, can solve problems such as strength, toughness, and creep resistance performance degradation, achieve low water expansion rate, prolong service life, and improve compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

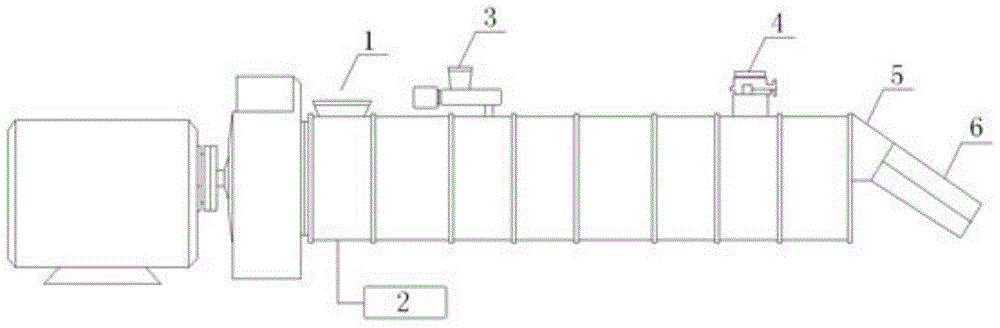

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: This embodiment is a silane crosslinked polyethylene wood-plastic composite material in parts by weight consisting of 100 parts of polyethylene, 40 to 100 parts of plant fiber, 2 to 5 parts of lubricant, 1 to 5 parts It is prepared from 0.1-0.5 parts of silane coupling agent, 0.1-0.5 parts of initiator, 0.005-0.05 parts of catalyst and 0.1-0.25 parts of antioxidant.

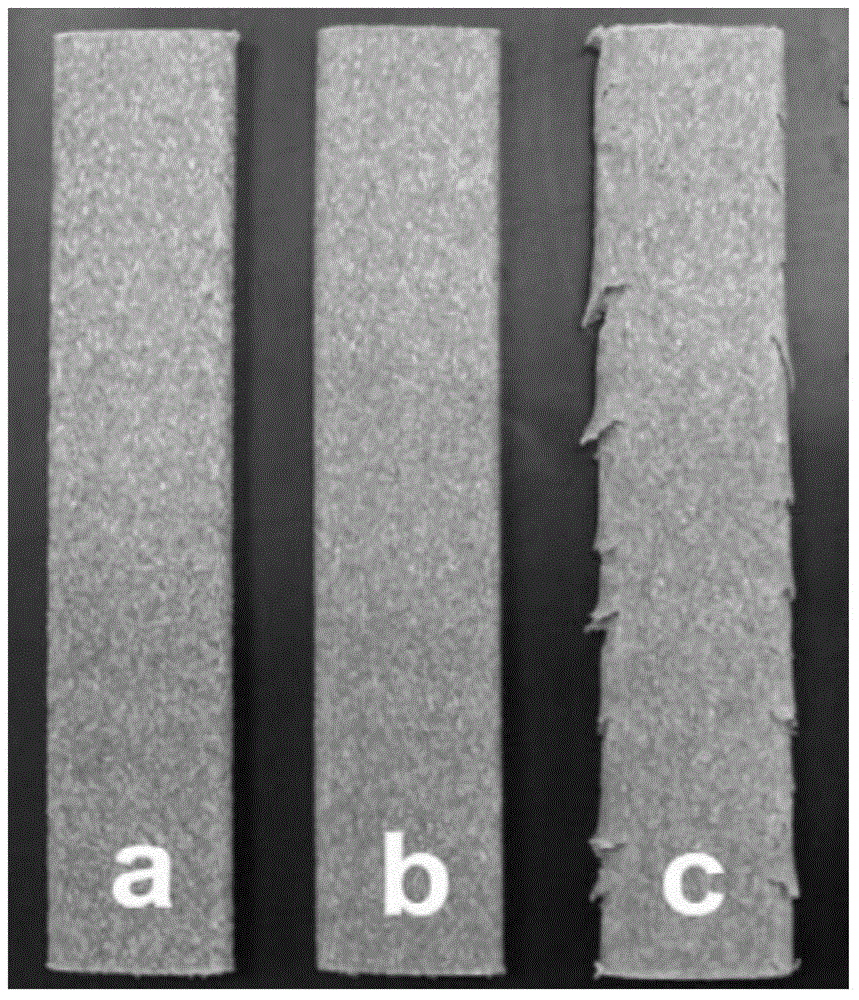

[0020] The silane cross-linked wood-plastic composite material prepared in this embodiment is to solve the problem that the strength, toughness, creep resistance and other properties of the PE wood-plastic composite material are reduced due to water absorption during long-term outdoor use. By adding peroxide initiator and silane coupling agent in the compounding process, the composite material forms a polyethylene matrix network cross-linked structure, and at the same time strengthens the interfacial adhesion of the cross-linked polyethylene wood-plastic composite. The principle of...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the polyethylene is one of high-density polyethylene, low-density polyethylene and linear low-density polyethylene or a mixture of several of them; The plant fiber is wood powder, straw powder, bamboo powder or chaff powder. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and one of the specific embodiments one or two is that the lubricant is one of stearic acid, zinc stearate, calcium stearate and polyethylene wax or A mixture of several of them; the silane coupling agent is vinyl silane. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com