A converter and its application

A converter and furnace body technology, applied in the field of non-ferrous metal smelting, can solve the problems of unrealistic industrialization, high pollution, and high energy consumption of oxygen-enriched molten pool smelting technology, and achieve improved reaction rate and lead recovery rate, uniform temperature distribution, The effect of speeding up the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

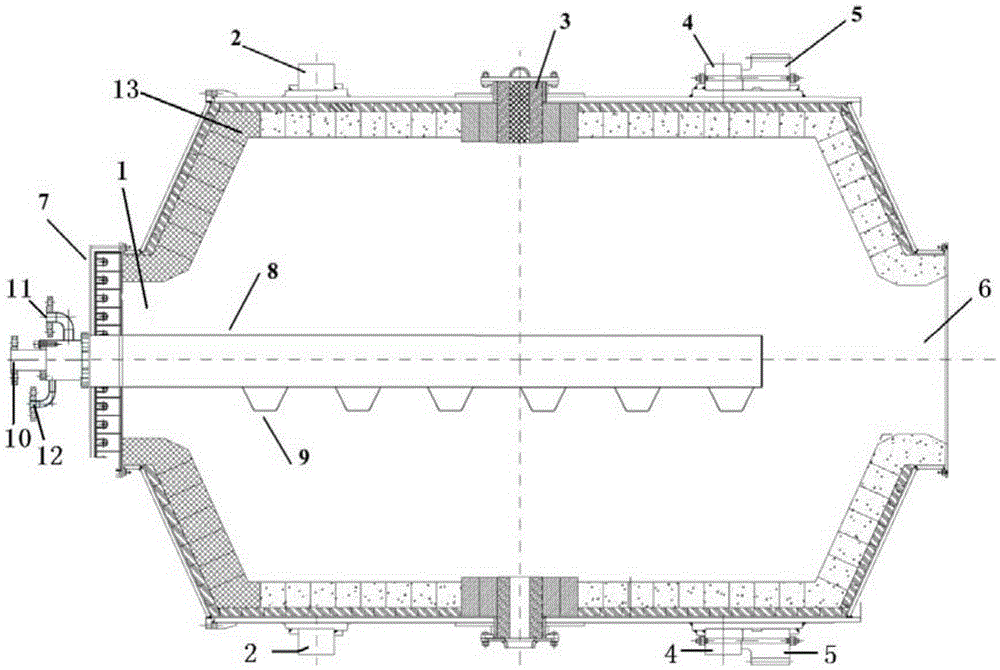

[0048]Design a rotary furnace with a furnace body size of 6300×φ3400mm, a fuel port of φ1300mm, a feed port of φ400mm, a φ300mm feed port, and a smoke exhaust port of φ400mm; the center of the smoke exhaust port (6) is located in the horizontal cylindrical furnace body on the horizontal axis.

[0049] The tests were carried out in the rotary furnace described above.

[0050] Preparation:

[0051] Take lead-containing 68.76% waste storage battery cement and mix lead-containing 93.12% broken grid, the mixed material contains lead 76.31%; the amount of sodium carbonate added is 40% of the relative lead material quality, and the amount of coal particles added is 40% of the relative lead material quality. 10%, add water to the above-mentioned materials in a cylinder granulator until the water content of the materials is 8%, and make pellets with a particle size of 5 mm to 18 mm for later use.

[0052] Smelting:

[0053] Add the above-mentioned pellets into 10t of mixed material ...

Embodiment 2

[0055] The melting furnace is the same as in Example 1.

[0056] Preparation:

[0057] Get lead-containing 68.76% waste storage battery cement mixed with lead-containing 20.14%, Au4g / t sulfide ore raw ore powder, the mixture contains lead 50.12%; the amount of sodium carbonate added is 50% of the relative lead material quality, and the amount of coal particles added is Relative to 10% of the mass of the lead material, add water to the above-mentioned material in a cylinder granulator until the material moisture is 8%, and make pellets with a particle size of 5 mm to 18 mm for use.

[0058] Smelting:

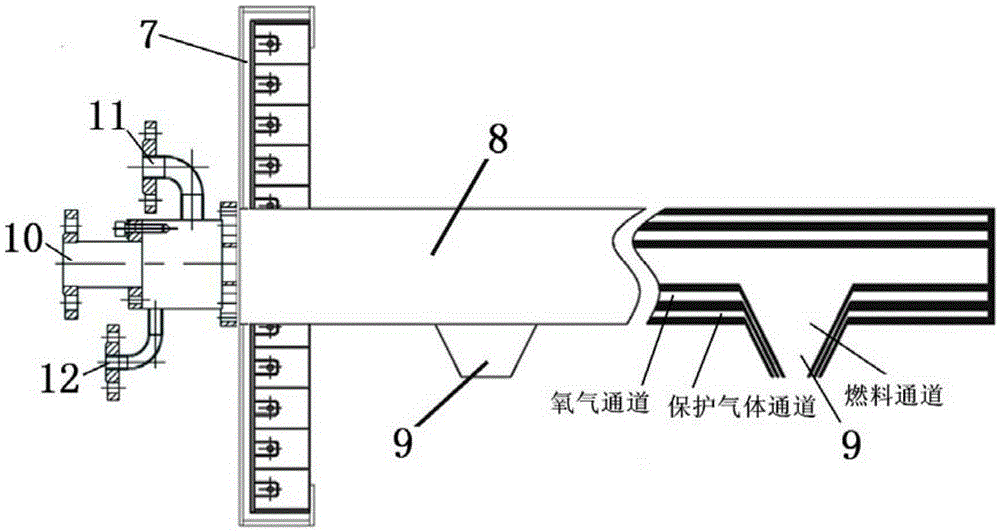

[0059] Add the above-mentioned pellets into 10t of mixed material into the above-mentioned rotary furnace, control the melting temperature between 800-900°C, and the flow rate of natural gas at 3000Nm 3 / h, pure oxygen flow rate is 500Nm 3 / h; protective gas is N 2 , the flow rate is 100Nm 3 / h, reaction time 2h. The lead recovery rate is 93.11%, the crude lead contains 99....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com