Preparation method of graphite oxide alkene materials in dissymmetrical structure

An asymmetric structure and graphene technology, applied in the field of materials, can solve the problems of high ionization degree of carboxyl groups and reduce the stability of Pickering emulsion, etc., and achieve the effect of low cost, good emulsion stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

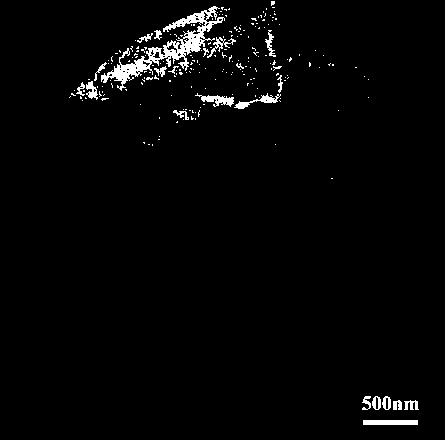

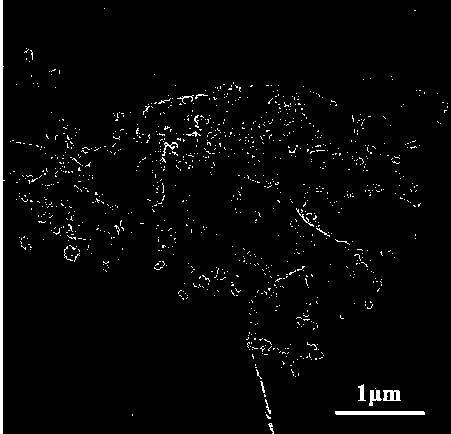

Image

Examples

Embodiment 1

[0025] 1. Add 1 part of graphene oxide to 100 parts of water, add 0.07 parts of hydrochloric acid and 2 parts of sodium chloride to the aqueous dispersion of graphene oxide, and disperse evenly by ultrasonication for 10 minutes. Add 50 parts of paraffin to the mixture, heat it in a water bath at 70°C for 10 min, keep the water bath, and homogenize at a speed of 20000 r / min for 10 min. After cooling to room temperature, centrifuge at 10,000 r / min for 3 min, and remove the water phase to obtain graphene oxide-coated paraffin microspheres.

[0026] 2. Dissolve the paraffin microspheres prepared above in 100 parts of 50% alcohol aqueous solution, add 2 parts of dodecylamine to it, and stir at room temperature for 12 h.

[0027] 3. After the reaction, wash with 50 parts of ethanol and centrifuge at 10000 r / min for 3 min. Then add 500 parts of chloroform, centrifuge at 10,000 r / min for 3 min, repeat three times to remove paraffin, and finally use 50 parts of ethanol to wash by cent...

Embodiment 2

[0029] 1. Experimental device and operation are the same as embodiment 1, change the graphene oxide in example 1 into 2 parts; Hydrochloric acid is changed into sulfuric acid, and its quality is 0.1 part; Sodium chloride is changed into magnesium chloride, and its quality is 5 parts; Paraffin wax quality Change it to 120 parts; change the water bath temperature to 65 °C; change the homogenization speed to 15000 r / min, and change the homogenization time to 15 min.

[0030] 2. Experimental device and operation are the same as embodiment 1, change the alcoholic aqueous solution in the example 1 into ethanol quality and be 80% of water quality; Change dodecylamine into octyldiamine, and its quality is 3 parts; Change the stirring time into 15 h.

[0031] 3. The experimental device and operation are the same as in Example 1, and the chloroform in Example 1 is changed to cyclohexane, and its mass is 1400 parts.

Embodiment 3

[0033] 1. Experimental device and operation are the same as embodiment 1, change the graphene oxide in the example 1 into 0.5 part; Hydrochloric acid is changed into acetic acid, and its quality is 0.1 part; Sodium chloride is changed into potassium chloride, and its quality is 1 part; The quality of paraffin was changed to 30 parts; the temperature of the water bath was changed to 60 °C; the homogenization was changed to ultrasonic, the ultrasonic power was 300W, and the ultrasonic time was 15min.

[0034] 2. The experimental device and operation are the same as in Example 1, changing the alcoholic aqueous solution in Example 1 into 90% of the water quality in ethanol quality; changing dodecylamine into 3-aminopropyltriethoxysilane, and its quality is 0.5 parts; change the stirring time to 20 h.

[0035] 3. The experimental device and operation are the same as in Example 1, except that the chloroform in Example 1 is changed to n-nonane, and its mass is 400 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com