Preparation method of graphene and graphene

A graphene and biomass material technology, applied in the field of carbon materials, can solve the problems of graphene surface damage, easy to pollute the environment, difficult to meet large-scale needs, etc., to achieve high electrical conductivity and electrochemical performance, high specific surface area, Good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

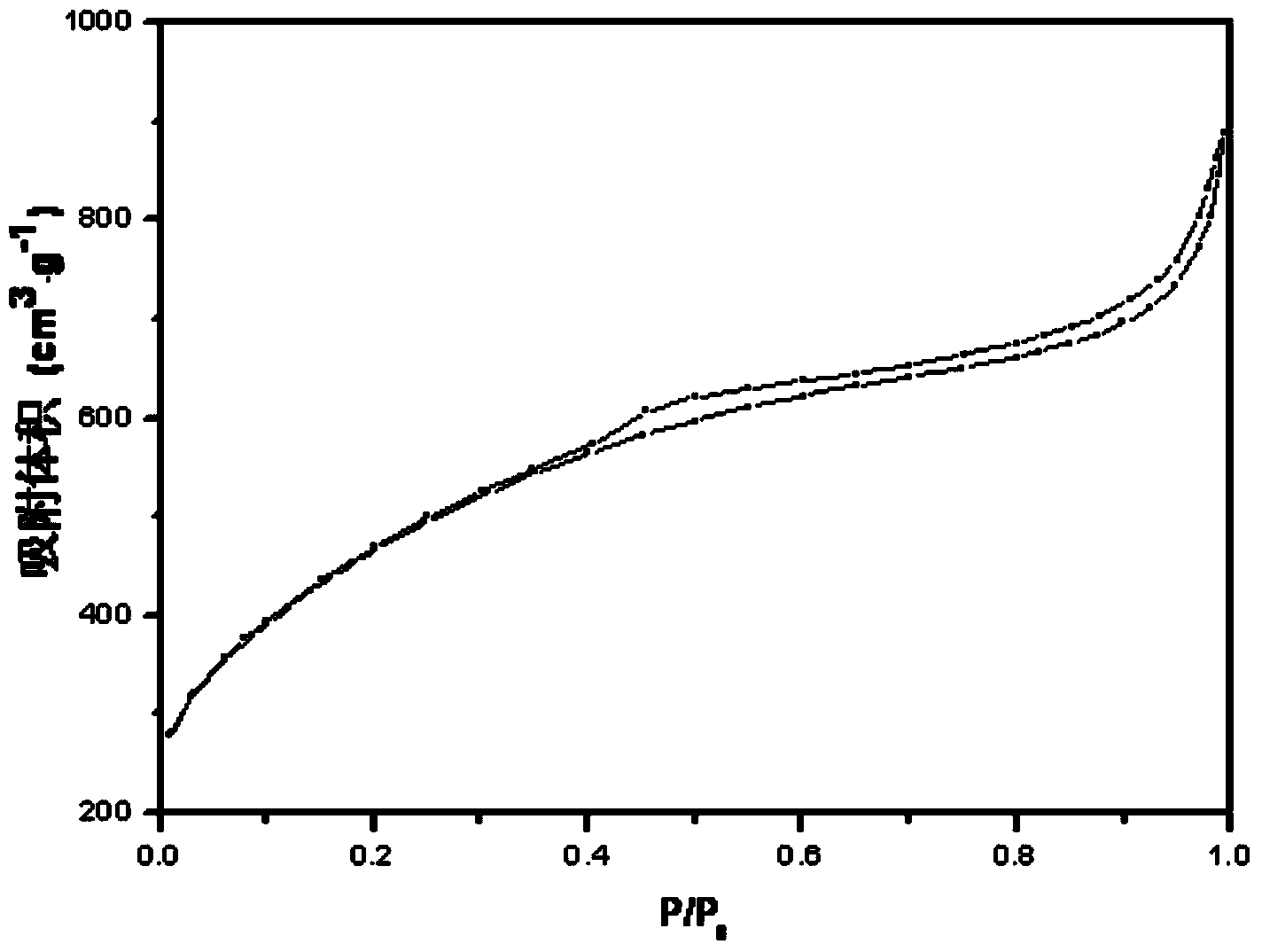

[0035] The invention provides a kind of preparation method of graphene, comprises the following steps:

[0036] A) Pretreating the biomass material to obtain a pretreated biomass material, the biomass material including one or more of agricultural and forestry waste, tea and seaweed plants;

[0037] B) mixing a metal catalyst, a solvent and the pretreated biomass material in the step A) to obtain a catalyst-loaded biomass material;

[0038] C) mixing the pore-forming agent with the catalyst-loaded biomass material obtained in step B), and heating at 700-1200° C. to obtain graphene.

[0039] The preparation method of graphene provided by the invention adopts biomass material as a carbon source, which reduces the cost of graphene and is beneficial to large-scale industrial production of graphene.

[0040] In the invention, the biomass material is pretreated to obtain the pretreated biomass material. The present invention preferably carries out pretreatment to described biomass...

Embodiment 1

[0077] Wash and dry Sargassum and crush it through a 60-mesh sieve, then soak 10g of Sargassum powder in 1000ml of 1mol / L sodium periodate aqueous solution, treat it at 50°C for 2h, and then dissolve the obtained product in 1000ml Concentration is the ethanol solution of the sodium hydroxide of 1mol / L, wash and dry after soaking at room temperature for 1h, obtain the pretreated Sargassum;

[0078] Add 5 g of pretreated Sargassum powder into 100 mL of aqueous solution containing 10 g of nickel acetate, stir for 6 hours, wash with deionized water and dry at 80 ° C to obtain Sargassum loaded with catalyst;

[0079] Mix the catalyst-loaded Sargassum with KOH, the mass ratio of the catalyst-loaded Sargassum to KOH is 2:1, add a small amount of water, let stand for 8 hours, and then blow dry at 120°C for 12 hours to obtain a dry product;

[0080] Then the obtained dried product was placed in a tube furnace, kept at 850° C. for 2 hours under an argon protective atmosphere, and taken ...

Embodiment 2

[0085] Wash and dry Sargassum and crush through a 60-mesh sieve, then soak 50g of Sargassum powder in 1000ml of 1mol / L KMnO 4 The solution was treated in an aqueous solution at 80°C for 2 hours, and then the obtained product was soaked in 1000 ml of ethanol solution of sodium hydroxide with a concentration of 0.8 mol / L at room temperature for 1 hour, then washed and dried to obtain pretreated Sargassum powder;

[0086] Take 10g pretreated Sargassum powder and 500mL containing 50g K 3 [Fe(CN) 6 ] aqueous solution, stirred for 6 hours, washed with deionized water and dried at 80°C to obtain Sargassum powder loaded with catalyst;

[0087] Mix the catalyst-loaded Sargassum powder with KOH, the mass ratio of the catalyst-loaded Sargassum powder to KOH is 5:1, add a small amount of water, let stand for 8 hours, and then blow dry at 100°C for 10 hours to obtain a dry product;

[0088] Then the obtained dried product was placed in a tube furnace, kept at 850° C. for 2 hours under an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com