Technical method for simultaneously preparing premna microphylla pectin and premna microphylla sodium copper chlorophyll from premna microphylla

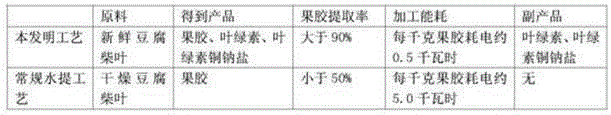

A copper chlorophyllin sodium salt and process technology, which is applied in the field of extraction and preparation of biological products, can solve the problems of inability to realize pectin and chlorophyll processed products, high moisture content of tofu wood, and decreased pectin yield, and achieve gel effect Good, the investment in production equipment can be large or small, and the effect of energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The specific operation steps for simultaneously preparing tofu chai pectin and tofu chai copper chlorophyllin sodium salt from doufuchai are as follows:

[0023] 1、 Tofu Chai Beating

[0024] Mix 1 kg of fresh tofu chai with 200 ml of beating agent (the mixing ratio is 1:0.2 by weight to volume), then beat with an electric beater, pass through a 20-mesh sieve, and remove the fibrous tissue that is difficult to sieve to obtain tofu chai pulp. The beating agent is prepared from water, methanol and acetone in a volume ratio of 0.1:0.1:0.1;

[0025] 2、 Preparation of chlorophyll extract

[0026] Centrifuge the bean curd pulp for 10 minutes at a speed of 10,000 rpm to obtain 500 milliliters of centrifuged supernatant and 400 grams of centrifuged sediment. Add 40 milliliters of chlorophyll extractant to this precipitate, the weight-to-volume ratio of material to liquid is 1:0.1, filter after mixing for 1 minute, obtain 40 milliliters of filtrate, combine filtrate and cent...

Embodiment 2

[0038] The specific operation steps for simultaneously preparing tofu chai pectin and tofu chai copper chlorophyllin sodium salt from doufuchai are as follows:

[0039] 1. Tofu chai beating

[0040] Mix 1 kg of fresh tofu chai with 1000 ml of beating agent (weight to volume ratio 1.0:1.0), then beat with an electric beater, and pass through a 100-mesh sieve to remove fibrous tissue that is difficult to sift through. The beating agent is composed of water, ethanol and acetone in a volume ratio of 1:2:1;

[0041] 2. Preparation of chlorophyll extract

[0042] The bean curd pulp was filtered under reduced pressure to obtain 1500 ml of filtrate and 300 g of filter residue. Add 180 ml of chlorophyll extractant (the weight-to-volume ratio of material to liquid is 1:0.6) to the filter residue, mix for 30 minutes, and then filter to obtain 180 ml of filtrate. Combine the two filtrates to obtain a total of 1680 ml of chlorophyll extract; Residue 300 grams. The chlorophyll extractan...

Embodiment 3

[0054] The specific operation steps for simultaneously preparing tofu chai pectin and tofu chai copper chlorophyllin sodium salt from doufuchai are as follows:

[0055] 1. Tofu chai beating

[0056] Mix 1 kg of fresh tofu chai with 500 ml of beating agent (weight to volume ratio: 1:0.5), beat with an electric beater, and pass through a 60-mesh sieve to obtain tofu chai pulp. The beating agent is made by mixing water, ethanol (or methanol) and acetone at a volume ratio of 0.5:1.0:0.5;

[0057] 2. Chlorophyll extraction

[0058] The bean curd pulp was filtered under reduced pressure to obtain 900 ml of filtrate and 400 g of filter residue. Add 120 ml of chlorophyll extractant (the weight-to-volume ratio of solid to liquid is 1:0.3) to the filter residue, mix for 15 minutes and then filter to obtain 120 ml of filtrate. Combine the two filtrates to obtain a total of 1020 ml of chlorophyll extract and filter residue 400 grams. The chlorophyll extractant is prepared from ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com