A method for preparing nano-copper/pamps composite microspheres assisted by ultrasound

An ultrasonic-assisted, composite microsphere technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of uncontrollable, broken, and uneven particle size of microspheres, and achieve controllable size, prevent agglomeration, and uniform particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

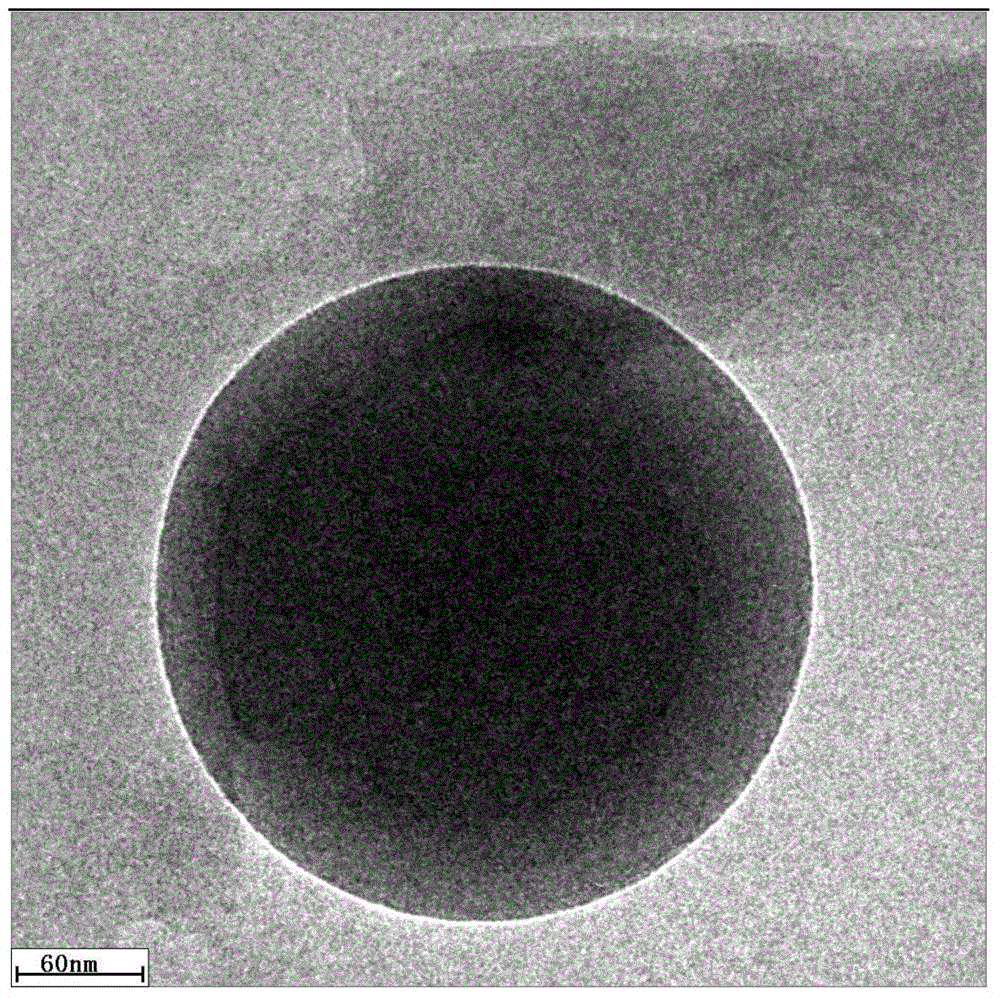

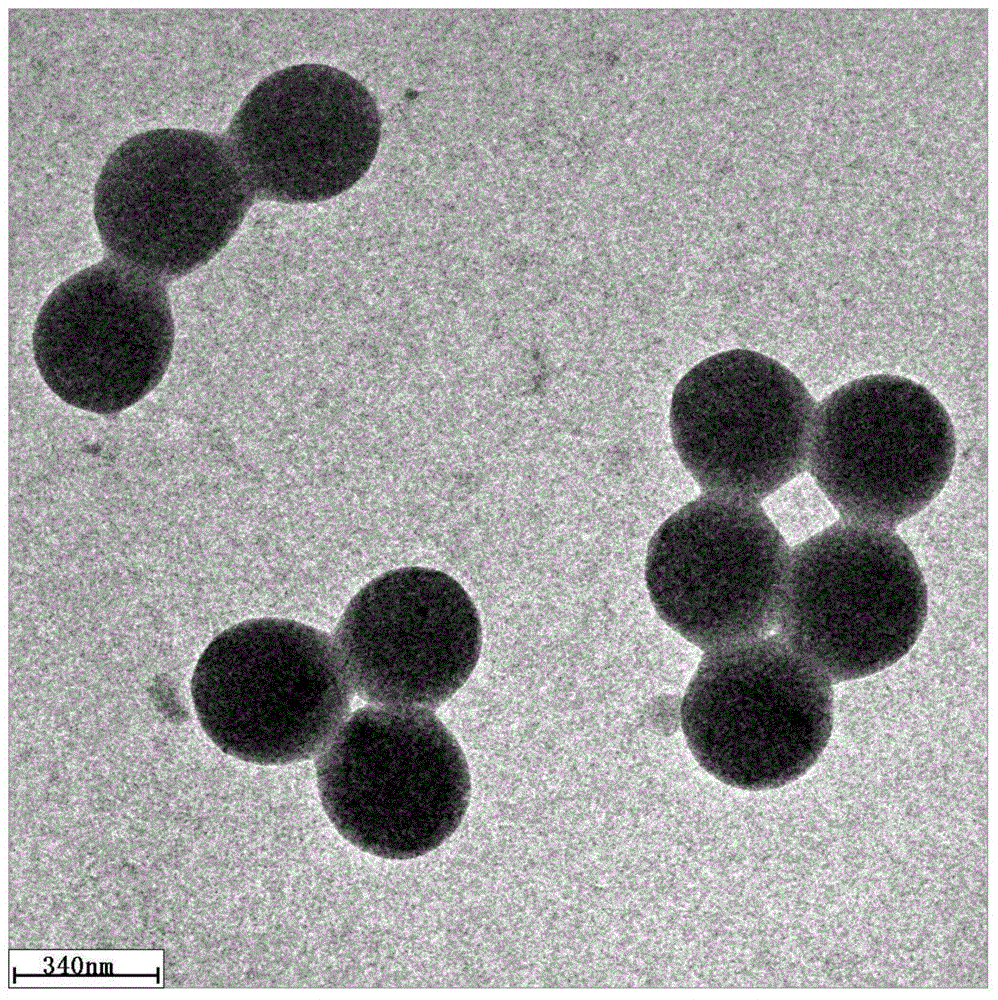

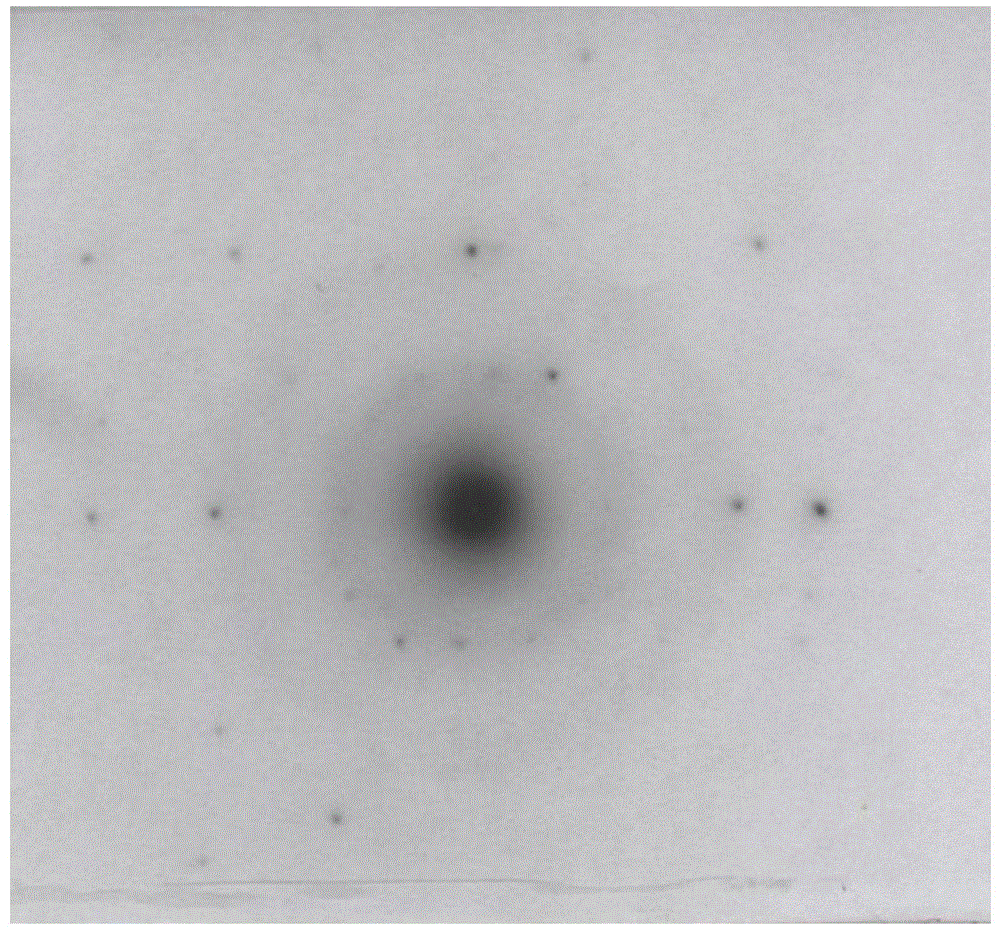

Image

Examples

Embodiment 1

[0031] An ultrasound-assisted method for preparing nano-copper / PAMPS composite microspheres, the operation steps are as follows: (1) 3g copper acetate, 0.01g vitamin C, 0.05g potassium persulfate, 2.50g 2-acrylamido 2-methyl Propanesulfonic acid and 50g of water are mixed uniformly to form a uniformly dispersed mixed solution. The mixed solution is irradiated ultrasonically under nitrogen protection. The temperature of the reaction system is controlled by circulating water to 35°C. The ultrasonic constant is set: ultrasonic 1s, gap 1s, ultrasonic time 5min, the ultrasonic power is 1000W, the ultrasonic frequency is 22kHz, and the reaction solution is obtained; (2) The mixed solution dispersion system after the reaction is placed in a vacuum drying oven for 5 days, and the temperature is controlled at 60°C and the pressure is 0.055MPa; (3) The vacuum drying oven is closed Power supply and return to normal pressure. After the reaction system is cooled together with the drying box,...

Embodiment 2

[0034] An ultrasound-assisted method for preparing nano-copper / PAMPS composite microspheres, the operation steps are as follows: (1) Combine 5g copper acetate, 0.08g vitamin C, 0.18g potassium persulfate, 5.50g 2-acrylamido 2-methyl Propanesulfonic acid and 70g water are mixed uniformly to form a uniformly dispersed mixed solution. The mixed solution is irradiated ultrasonically under nitrogen protection. The temperature of the reaction system is controlled by circulating water at 45°C. The ultrasonic constant is set: ultrasonic 1s, gap 1s, ultrasonic time 10min, ultrasonic power of 1000W, ultrasonic frequency of 22kHz, the reaction solution is obtained; (2) The mixed solution dispersion system after the reaction is placed in a vacuum drying oven for 7 days, and the temperature is controlled at 80°C and the pressure is 0.095MPa; (3) The vacuum drying oven is closed Power supply and return to normal pressure. After the reaction system is cooled together with the drying box, the p...

Embodiment 3

[0037] An ultrasound-assisted method for preparing nano-copper / PAMPS composite microspheres, the operation steps are as follows: (1) 4g copper acetate, 0.04g vitamin C, 0.11g potassium persulfate, 4.00g 2-acrylamido 2-methyl Propanesulfonic acid and 60g of water are mixed uniformly to form a uniformly dispersed mixed solution. The mixed solution is irradiated ultrasonically under nitrogen protection. The temperature of the reaction system is controlled by circulating water to 40℃. The ultrasonic constant is set: ultrasonic 1s, gap 1s, ultrasonic time 8min, ultrasonic power of 1000W, ultrasonic frequency of 22kHz, the reaction solution is obtained; (2) The mixed solution dispersion system after the reaction is placed in a vacuum drying oven for 6 days, and the temperature is controlled at 70°C and the pressure is 0.075MPa; (3) The vacuum drying oven is closed Power supply and return to normal pressure. After the reaction system is cooled together with the drying box, the product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com