Ultraviolet-absorbing coating and preparation method thereof

A technology of ultraviolet rays and coatings, applied in the field of ultraviolet absorbing coatings and their preparation, can solve the problems of easy decomposition and volatilization after long-term use, and achieve the effect of excellent ultraviolet absorption performance, not easy to degrade, and excellent ultraviolet absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

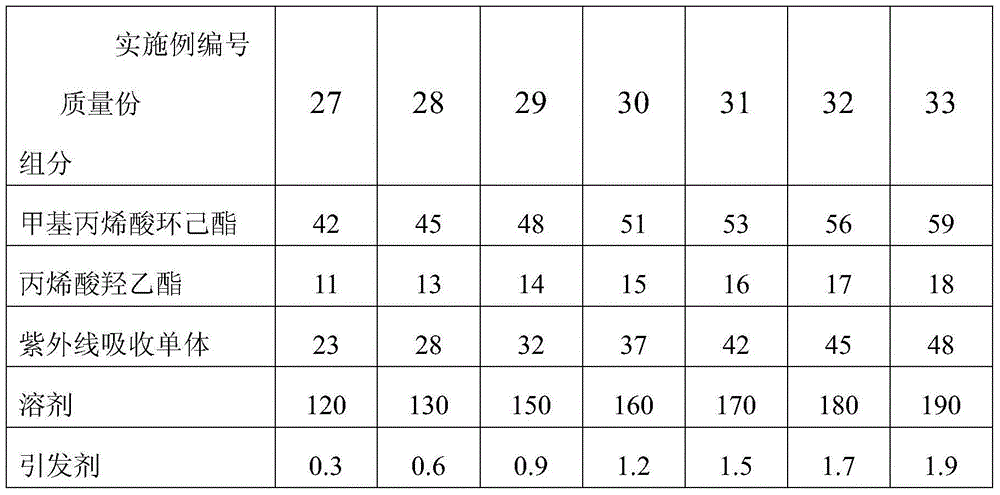

Examples

Embodiment 1

[0021] Mix 40kg of cyclohexyl methacrylate, 10kg of hydroxyethyl acrylate, 25kg of 2-[2-hydroxy-5-[2-(methacryloyloxy)ethyl]phenyl]-2H-benzene at room temperature Add triazole, 100kg of toluene and 0.4kg of azobisisobutylcyanide into the reaction kettle with a condensing reflux device, so that the temperature of the condenser is controlled below 15°C, stirring at a rotation speed of 100-300rpm, and mixing evenly; Under the protection of nitrogen, the temperature was gradually raised to 75° C., the copolymerization reaction was carried out for 4 hours, and the heating was stopped to obtain an ultraviolet absorbing coating. The ultraviolet absorbing paint is a light yellow transparent liquid with a solid content of 26.8% and a viscosity of 22 seconds (coated with 4# cup, 25°C).

Embodiment 2

[0023] Mix 55kg of cyclohexyl methacrylate, 14kg of hydroxyethyl acrylate, 30kg of 2-[2-hydroxy-5-[2-(methacryloyloxy)ethyl]phenyl]-2H-benzene at room temperature Triazole, 160 ㎏ ethyl acetate and 1.7 ㎏ initiator (benzoyl peroxide: azobisisobutylcyanide=1:3 mass ratio) join in the reactor with condensing reflux device, make the condenser The temperature is controlled below 15°C, stirred at a rotation speed of 100-300rpm, and mixed evenly; under the protection of nitrogen, the temperature is gradually raised to 77°C, and the copolymerization reaction is carried out for 6 hours, and the heating is stopped to obtain an ultraviolet absorbing coating. The ultraviolet absorbing paint is a light yellow transparent liquid with a solid content of 37.3% and a viscosity of 33 seconds (coated with 4# cup, 25°C).

Embodiment 3

[0025] Mix 60kg of cyclohexyl methacrylate, 20kg of hydroxyethyl acrylate, 20kg of 2-[2-hydroxy-5-[2-(methacryloyloxy)ethyl]phenyl]-2H-benzene at room temperature Add triazole, 190kg of solvent (ethyl acetate:toluene=2:5 mass ratio) and 2.0kg of benzoyl peroxide into the reaction kettle with condensing reflux device, so that the temperature of the condenser is controlled below 15°C , stirring at a rotation speed of 100-300rpm, and mixing evenly; under the protection of nitrogen, the temperature was gradually raised to 80°C, and the copolymerization reaction was carried out for 5 hours, and the heating was stopped to obtain an ultraviolet absorbing coating. The ultraviolet absorbing paint is a light yellow transparent liquid with a solid content of 33.2% and a viscosity of 25 seconds (coated with 4# cup, 25°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com