Combined hydrate inhibitor

A technology of hydrate inhibitor and composite inhibitor, which is applied in drilling compositions, pipeline systems, chemical instruments and methods, etc., can solve the problems of limited application occasions, limited dispersion performance, hydrate eruption, etc. Friendly, good inhibitory effect, high inhibitory activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

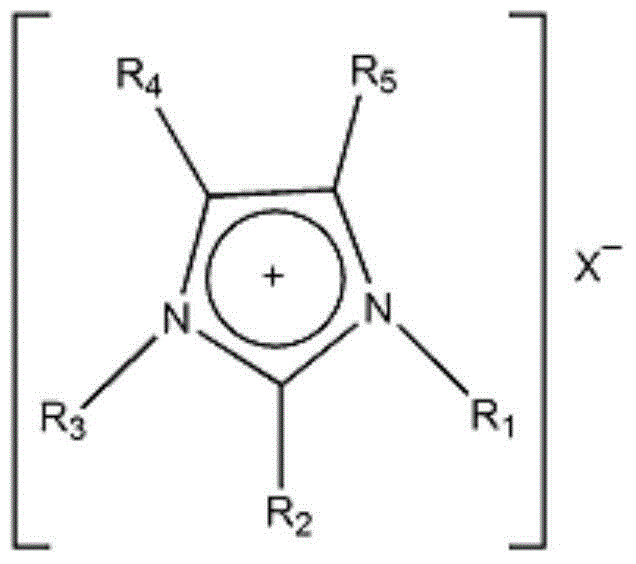

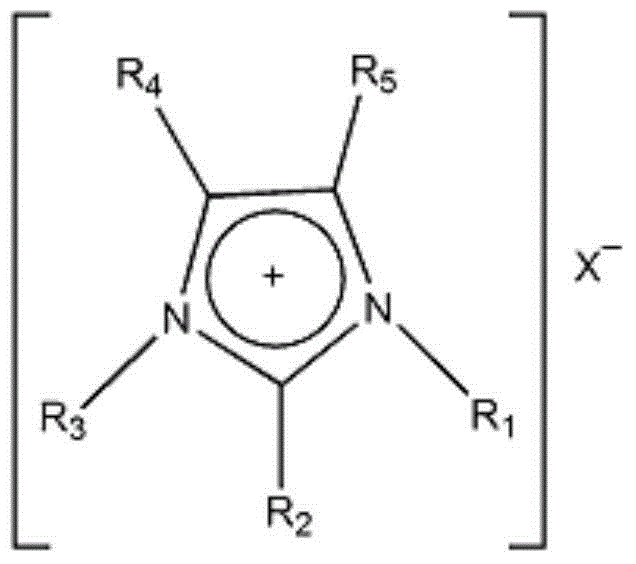

[0039] A combined hydrate inhibitor, comprising 0.05% PVCap with a weight-average molecular weight of 900 to 40,000 and 0.05% 1-ethyl-3-methylimidazolium tetrafluoroborate ([C 2 min]BF 4 ) and water, and the combined hydrate inhibitor was configured as a composite aqueous solution with a mass concentration of 0.1% and added to the reactor. The experimental procedure was the same as above. The results showed that the induction time of hydrate formation under this system was 12 minutes. The reaction completion time is 105 minutes, and the pressure drop in the reaction is 1.39MPa, which has a good inhibitory effect.

Embodiment 2

[0041] A combined hydrate inhibitor, comprising PVCap with a mass concentration of 0.5% weight-average molecular weight of 900 to 40000, 0.05% 1-ethyl-3-methylimidazolium tetrafluoroborate ([C 2 min]BF 4 ) and water, and the combined hydrate inhibitor was configured into a composite aqueous solution with a mass concentration of 0.55% and added to the reactor. The experimental procedure was the same as above. The results showed that the induction time of hydrate formation under this system was 39 minutes. The completion time of the reaction was 151 minutes, and the pressure drop in the reaction was 1.25 MPa, which had a good inhibitory effect.

Embodiment 3

[0043] A combined hydrate inhibitor, comprising 0.5% PVCap with a weight-average molecular weight of 900 to 40,000 and 0.5% 1-ethyl-3-methylimidazolium tetrafluoroborate ([C 2 min]BF 4 ) and water, the combined hydrate inhibitor is configured into a composite aqueous solution with a mass concentration of 1.0% and added to the reactor. The experimental procedure is the same as above. The results show that the induction time of hydrate formation under this system is 88min, and the reaction time is 88 minutes. The completion time is 259min, and the pressure drop in the reaction is 1.0MPa, which has a good inhibitory effect.

[0044] Comparing Example 3 with Comparative Examples 1 and 4, it can be seen that the combined use of the kinetic inhibitor PVCap and imidazolium ionic liquid can reduce the influence of the inhibitor on the degree of supercooling and produce a better inhibitory effect: the induction time of the hydrate is prolonged , the reaction takes longer to complete a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com