Multi-stage oxidization treatment technology for sludge

A technology of oxidation treatment and sludge, applied in sludge treatment, oxidation treatment of sludge, water/sludge/sewage treatment, etc. Biochemical enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

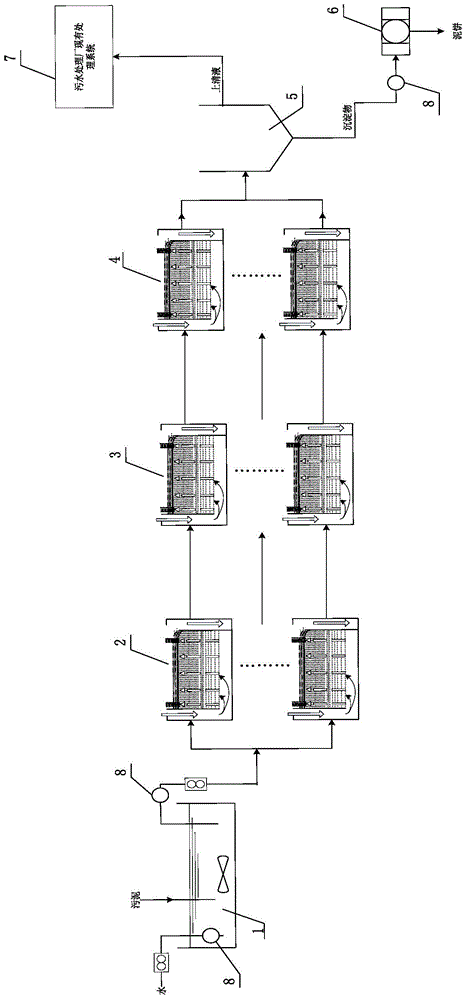

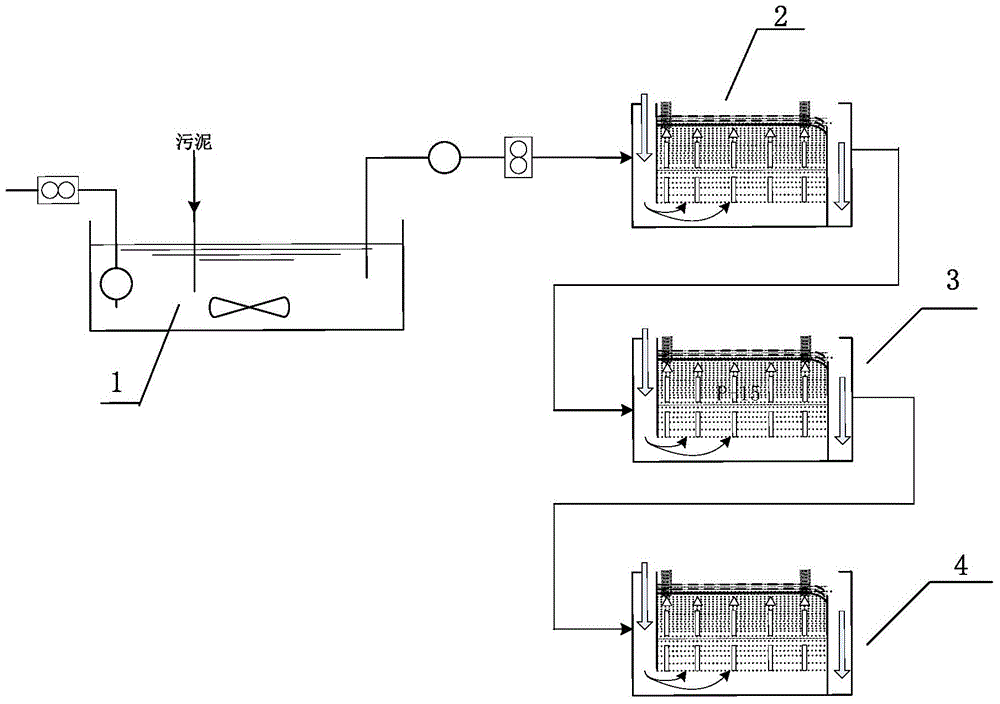

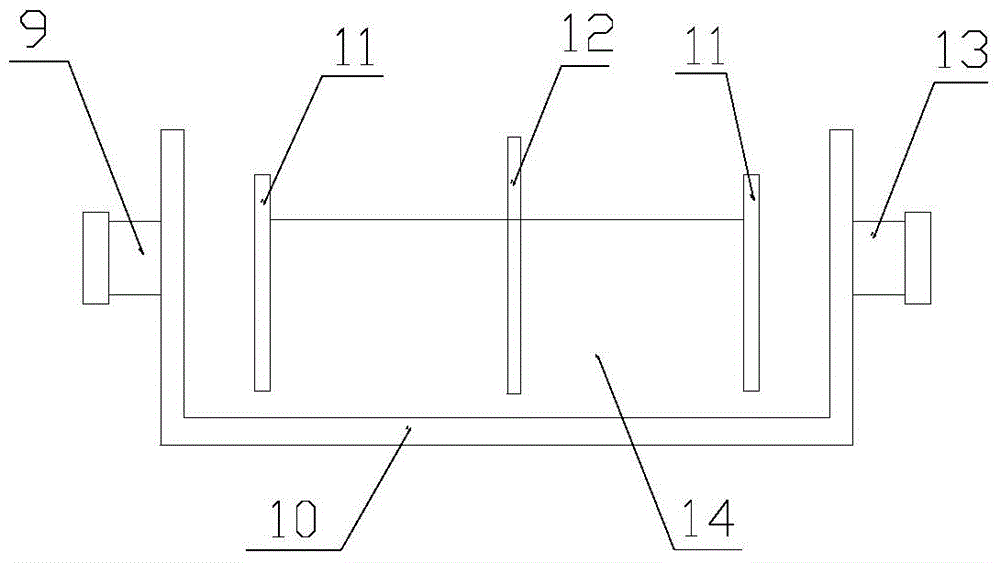

[0028] The volume of the oxidation reaction tank used is 120 liters, and the untreated sludge from the sewage treatment plant is passed into the adjustment tank 1, and reclaimed water is passed into the adjustment tank 1, so that the moisture content of the sludge is adjusted to 99.0%~99.6%; set 15 oxidation reaction pools, of which the primary oxidation reaction pool group 2 contains five oxidation reaction pools, the secondary oxidation reaction pool group 3 contains five oxidation reaction pools, and the third-stage oxidation reaction pool 4 contains five oxidation reaction pools. The final sludge passes through the primary oxidation reaction pool group 2, the secondary oxidation reaction pool group 3 and the tertiary oxidation reaction pool group 4 successively according to the flow rate of 0.6 cubic / hour, and the current density of the micro-current connected in the oxidation reaction pool is 3mA / cm 2After the sludge passes through the oxidation reaction tank groups at va...

Embodiment 2

[0030] The volume of the oxidation reaction tank used is 750 liters, and the untreated sludge from the sewage treatment plant is passed into the regulating tank 1, and reclaimed water is passed into the regulating tank 1, so that the moisture content of the sludge is adjusted to 99.0%~99.6%; set 15 oxidation reaction pools, wherein the primary oxidation reaction pool group 2 contains five oxidation reaction pools, the secondary oxidation reaction pool group 3 contains five oxidation reaction pools, and the tertiary oxidation reaction pool group 4 contains five oxidation reaction pools. The adjusted sludge passes through the primary oxidation reaction pool group 2, the secondary oxidation reaction pool group 3 and the tertiary oxidation reaction pool group 4 sequentially at a flow rate of 2 cubic meters per hour. The current density of the microcurrent connected in the oxidation reaction pool is 3mA / cm 2 , after the sludge passes through the oxidation reaction tank group succes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com