A kind of preparation method of low-viscosity, high-purity yeast mannan

A yeast mannan, high-purity technology, applied in the field of yeast mannan preparation, can solve the problems of unsuitable aqueous phase system, high protein removal rate, low price, etc., to reduce the time required for enzymatic hydrolysis, protein removal High removal rate and improved functional properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

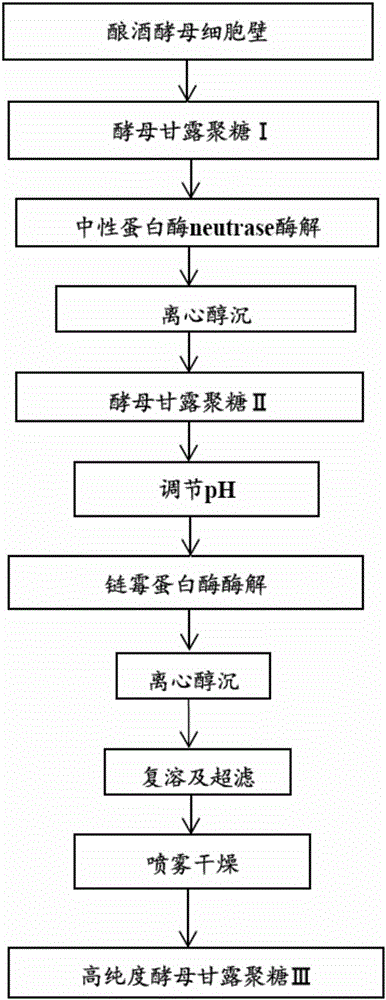

[0047] A preparation method of high-purity yeast mannan, through the following process steps (such as figure 1 shown):

[0048] (1) Using the cell wall of Saccharomyces cerevisiae as raw material, the crude yeast mannan I (purity: 76.60%) was prepared by water extraction and alcohol precipitation;

[0049] (2) adding deionized water to dissolve the crude yeast mannan obtained in step (1), and stirring until uniformly dispersed, so that the final concentration of the crude yeast mannan solution is 15% (w / v);

[0050] (3) enzymatically treat the solution obtained in step (2) with neutral protease neutrase, the consumption of neutral protease neutrase is 0.05% of the protein content in the crude product yeast mannan obtained in step (1), enzymolysis temperature and time Respectively 45 ℃, 2h;

[0051] (4) centrifuging the enzymolysis solution obtained in step (3), the centrifugal speed and time are respectively 4000rpm and 10min;

[0052] (5) Take the supernatant obtained in s...

Embodiment 2

[0061] A preparation method of high-purity yeast mannan, through the following process steps (such as figure 1 shown):

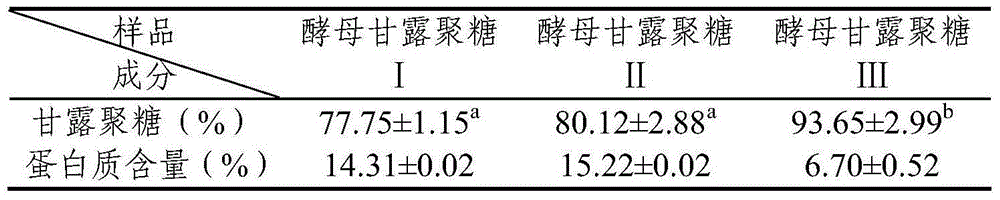

[0062] (1) Using the cell wall of Saccharomyces cerevisiae as raw material, the crude yeast mannan I (purity: 77.75%) was prepared by water extraction and alcohol precipitation;

[0063] (2) adding deionized water to dissolve the crude yeast mannan obtained in step (1), and stirring until uniformly dispersed, so that the final concentration of the crude yeast mannan solution is 15% (w / v);

[0064] (3) enzymatically treat the solution obtained in step (2) with neutral protease neutrase, the consumption of neutral protease neutrase is 0.05% of the protein content in the crude product yeast mannan obtained in step (1), enzymolysis temperature and time Respectively 45 ℃, 2h;

[0065] (4) Centrifuge the enzymolysis solution obtained in step (3), the centrifugal speed and time are respectively 5000rpm, 5min;

[0066] (5) Take the supernatant obtained in step (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com