Preparation method for ultraviolet curable linear urea formaldehyde resin

A technology of urea-formaldehyde resin and ultraviolet light, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problem of less urea-formaldehyde resin, achieve fast curing speed, excellent comprehensive performance, and facilitate automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

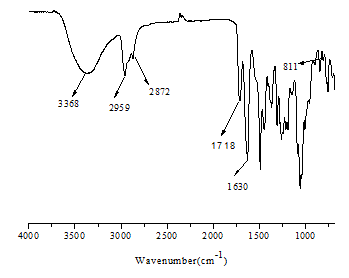

Image

Examples

Embodiment 1

[0031] In parts by mass, the following examples are the same.

[0032] 1) Modification of urea-formaldehyde resin: Dissolve an appropriate amount of urea-formaldehyde resin (molecular weight: 2750) in methanol, add sodium borohydride at -30°C for reduction, and react for 16 hrs, then remove the solvent by rotary evaporation to obtain Hydroxyl urea-formaldehyde resin (45% solids).

[0033] 2) A four-necked flask, a mechanical stirrer, a constant pressure funnel, a condenser and a thermometer are installed on the oil bath, and 11 parts of isophorone diisocyanate (IPDI) passed through nitrogen, the amount of modified urea-formaldehyde with hydroxyl 0.04% of the total mass of resin and IPDI was added to a four-necked flask, and slowly added 80 parts of modified urea-formaldehyde resin with hydroxyl groups at a temperature of 40 ° C. After 40 minutes, the dropwise addition was completed, and the temperature was raised. To 55°C, react at this temperature for 2 hrs, and the reaction...

Embodiment 2

[0036] 1) Modification of urea-formaldehyde resin: Dissolve an appropriate amount of urea-formaldehyde resin (molecular weight: 2750) in methanol, add sodium borohydride at -30°C for reduction, and react for 16 hrs, then remove the solvent by rotary evaporation to obtain Hydroxyl urea-formaldehyde resin (45% solids).

[0037] 2) A four-necked flask, a mechanical stirrer, a constant pressure funnel, a condenser and a thermometer are installed on the oil bath, and 9 parts of dicyclohexylmethane diisocyanate (HMDI) passed through nitrogen, the amount of which is modified with hydroxyl 0.05% of the total mass of urea-formaldehyde resin and HMDI was added to a four-necked flask, and 82 parts of modified urea-formaldehyde resin with hydroxyl groups were slowly added dropwise at a temperature of 40°C. After 30 minutes, the dropwise addition was completed and the temperature was raised To 55°C, react at this temperature for 2 hrs, and the reaction is always carried out under the prote...

Embodiment 3

[0040] 1) Modification of urea-formaldehyde resin: Dissolve an appropriate amount of urea-formaldehyde resin (molecular weight: 2750) in methanol, add sodium borohydride at -30°C for reduction, and react for 14 hrs, then remove the solvent by rotary evaporation to obtain Hydroxyl urea-formaldehyde resin (45% solids).

[0041] 2) A four-necked flask, a mechanical stirrer, a constant pressure funnel, a condenser and a thermometer are installed on the oil bath, and 10 parts of toluene diisocyanate (TDI) passed through nitrogen, the amount of which is the modified urea-formaldehyde resin with hydroxyl and Add 0.04% of the total mass of TDI dibutyltin dilaurate into a four-necked flask, and slowly add 83 parts of modified urea-formaldehyde resin with hydroxyl groups dropwise at a temperature of 50 ° C. After 40 min, the dropwise addition is completed, and the temperature is raised to 55 °C. °C, react at this temperature for 3 hrs, and the reaction is always carried out under the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com