Liquid plastic mulch and preparation method thereof

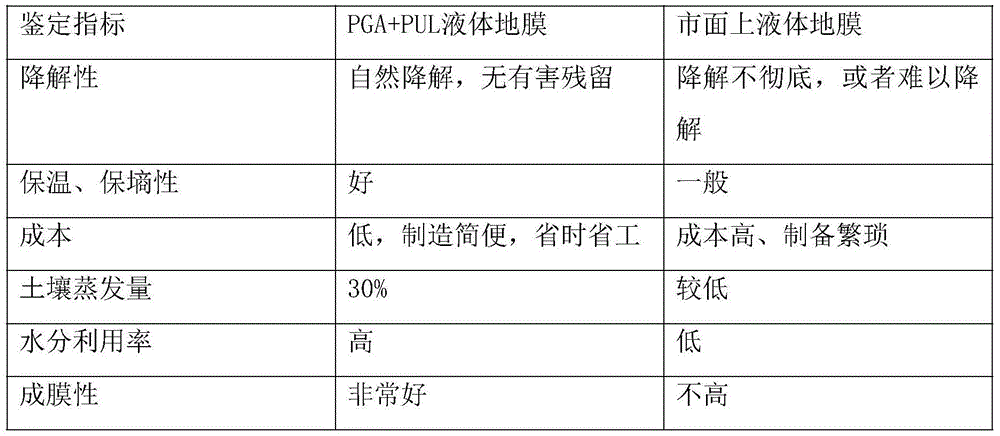

A liquid mulch and seed technology, applied in the agricultural field, can solve the problems of poor biodegradability of liquid mulch, poor soil water and fertilizer retention, and lower soil pH, so as to achieve excellent physical and chemical properties of soil, increase crop yield, and improve soil Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A liquid mulching film, the weight percentage of each component is: pullulan 5%, polyglutamic acid 5%, and the balance is water.

[0038] The pullulan polysaccharide is prepared by the following method: fermentation medium composition (1L): sucrose 150g, peptone 5g, sodium chloride 3g, dipotassium hydrogen phosphate 7g, magnesium sulfate 0.4g, ferrous sulfate 0.5g, all the other are distilled water , initial pH5.5.

[0039] The CGMCC.NO.7055 strain was inoculated into the seed medium in an amount of 3% (v / v) for shake flask activation, the rotation speed was 200 rpm, the temperature was 28° C., and the incubation time was 32 hours. The activated seed culture solution was transferred to a new seed shake flask in an amount of 3% (v / v) for expanded cultivation, the rotation speed was 200 rpm, the temperature was 28° C., and the cultivation time was 18 hours to obtain a seed solution. The composition of the seed medium (100 mL): 10 g of sucrose, 0.3 g of yeast extract powd...

Embodiment 2

[0048] The weight percent content of each component of the liquid film is: 5% of pullulan, 5% of polyglutamic acid and the balance of water.

[0049] The preparation method of the liquid film comprises the following steps: dispersing 5% pullulan and 5% polyglutamic acid in water at 32-36° C., stirring for 5 minutes, and mixing uniformly to obtain the liquid film.

[0050] Described polyglutamic acid is prepared by following method:

[0051] Activation of bacterial classification: inoculate with the amount of 5% (v / v) on the slant of nutrient-rich solid medium, cultivate at 37 ℃ for 16 hours, prepare mature slant seeds, the composition of solid medium comprises (1L): Peptone 10g, yeast powder 5g, sodium chloride 10g, agar 20g, pH7.2;

[0052] Preparation of seed solution: transfer one ring of the above seeds into a triangular flask containing nutrient-rich liquid medium, cultivate at 37°C and 220rpm for 16 hours to logarithmic growth phase; prepare seed medium according to the...

Embodiment 3

[0056] A liquid mulching film, the weight percentage of each component is: 1% of pullulan, 1% of polyglutamic acid, and the balance is water.

[0057] Described pullulan is prepared by the following method: fermentation medium composition (1L): sucrose 100g, peptone 10g, sodium chloride 5g, dipotassium hydrogen phosphate 10g, magnesium sulfate 0.6g, ferrous sulfate 1g, all the other are distilled water , initial pH6.5.

[0058] The CGMCC.NO.7055 strain was inoculated into the seed medium for shake flask activation, the rotation speed was 150 rpm, the temperature was 28°C, and the culture time was 30 hours. The activated seed culture solution was transferred to a new seed shake flask in an amount of 2% (v / v) for expanded cultivation, the rotation speed was 150 rpm, the temperature was 28° C., and the cultivation time was 20 hours. The composition of the seed medium (100 mL): 10 g of sucrose, 0.3 g of yeast extract powder, 0.25 g of sodium chloride, 0.2 g of dipotassium hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com