A kind of preparation method of immobilized enzyme

A technology of immobilizing enzymes and methyl acrylate, applied in directions such as being immobilized on/in an organic carrier, can solve the problems of difficulty in large-scale production and application, cumbersome processes, etc., to reduce non-specific interactions and simplify the process. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for immobilized enzyme, comprising the following steps:

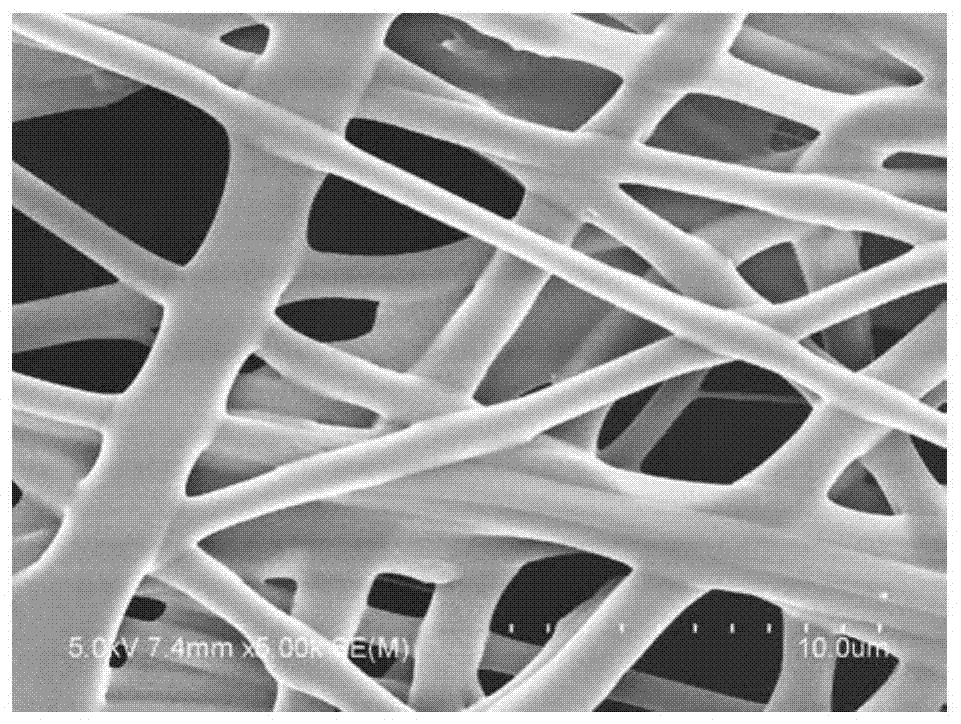

[0030] (1), the mass ratio of keratin and poly(methyl acrylate-acrylic acid) is added into N,N-dimethylformamide solvent according to 1:19 to form a solution with a total mass fraction of 30%, and magnetically stirred at room temperature until Completely dissolve to obtain a uniform spinning solution, inject it into the electrospinning device, and electrospin under the conditions of a voltage of 18kV, a spinning flow rate of 0.2ml / h, and a receiving distance of 20cm to obtain a diameter of 600nm. Poly(methyl acrylate-acrylic acid) composite nanofiber membrane, the composite nanofiber membrane was dried in a vacuum oven at 25°C for 5 hours to obtain a composite nanofiber membrane of keratin and poly(methyl acrylate-acrylic acid), Observe the morphology and structure of composite nanofibers, such as figure 1 shown.

[0031] Wherein, the mass ratio of methyl acrylate to acrylic acid of the pol...

Embodiment 2

[0035] A preparation method for immobilized enzyme, comprising the following steps:

[0036](1), the mass ratio of keratin and poly(methyl acrylate-acrylic acid) is added into N,N-dimethylformamide solvent according to 1:4 to form a solution with a total mass fraction of 26%, and magnetically stir at room temperature until Completely dissolve to obtain a uniform spinning solution, inject it into the electrospinning device, and electrospin under the conditions of a voltage of 16kV, a spinning flow rate of 0.6ml / h, and a receiving distance of 15cm to obtain a diameter of 300nm. The poly(methyl acrylate-acrylic acid) composite nanofiber membrane is dried in a vacuum oven at 40° C. for 10 hours to obtain a composite nanofiber membrane of keratin and poly(methyl acrylate-acrylic acid).

[0037] The mass ratio of methyl acrylate to acrylic acid of the poly(methyl acrylate-acrylic acid) is 9:1.

[0038] (2) Weigh 5 mg of keratin and poly(methyl acrylate-acrylic acid) composite nanof...

Embodiment 3

[0043] A preparation method for immobilized enzyme, comprising the following steps:

[0044] (1), the mass ratio of keratin and poly(methyl acrylate-acrylic acid) was added into N,N-dimethylformamide solvent to form a 28% solution at a mass ratio of 1:9, and magnetically stirred at room temperature until it was completely dissolved. Obtain uniform spinning liquid, inject in the electrospinning device, be 18kV at the voltage, the spinning flow rate is 0.6ml / h, under the condition that receiving distance is 20cm, obtain the 400nm diameter keratin and poly(acrylic acid) methyl ester-acrylic acid) composite nanofiber membrane, the composite nanofiber membrane was dried in a vacuum oven at 25°C for 5 hours to obtain a composite nanofiber membrane of keratin and poly(methyl acrylate-acrylic acid). The mass ratio of methyl acrylate to acrylic acid of the poly(methyl acrylate-acrylic acid) is 19:1.

[0045] (2) Weigh 5 mg of keratin and poly(methyl acrylate-acrylic acid) composite na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com