Negative plate of lithium ion capacitor and lithium ion capacitor using the negative plate

A lithium ion and capacitor technology, applied in the field of electrochemical energy storage devices, can solve the problems of limited energy density, high production cost, and increased lithium ion diffusion time, so as to achieve improved energy density and power density, low cost, and high current The effect of charging and discharging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

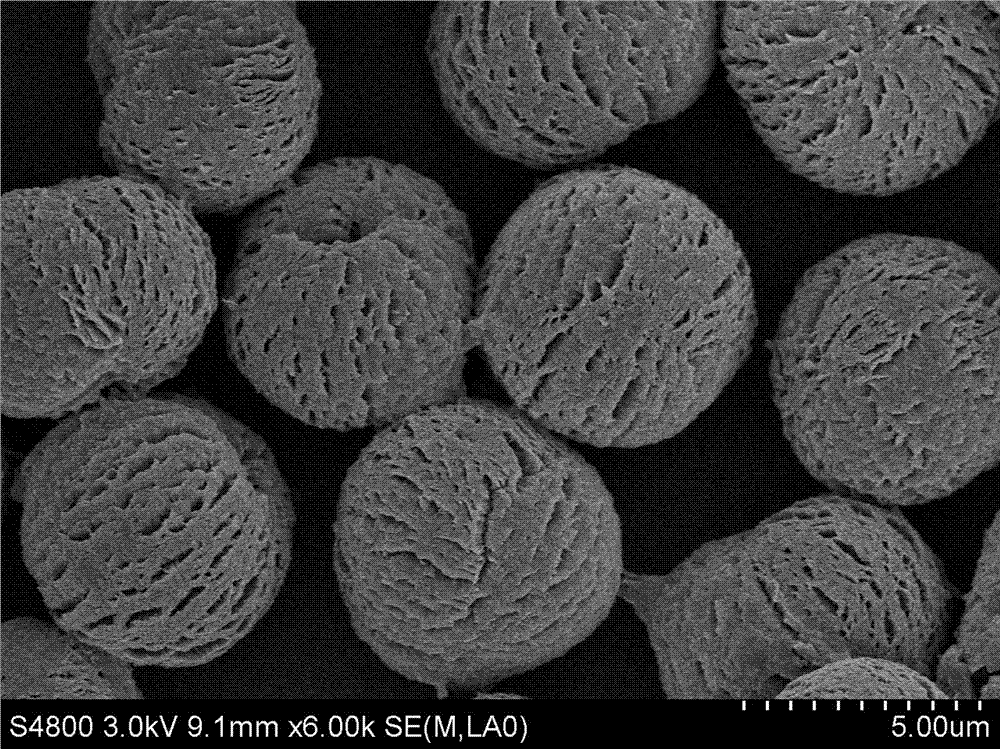

[0025] Preparation of spherical polyimide carbon material: 4,4'-diaminodiphenyl ether was added to a 250ml three-necked flask, and argon gas was introduced to let the entire reaction under the protection of argon gas. Pour in an appropriate amount of N,N'-dimethylformamide and place it in a water bath at 80 degrees Celsius and stir to dissolve. Then add polyvinylpyrrolidone to the solution and stir for 10min to dissolve. After that, pyromellitic anhydride was added to the solution three times, and the interval between each addition was not less than 10 minutes. After all the pyromellitic anhydride is added, pour the remaining N,N'-dimethylformamide and stir at 80°C for 4-6 hours to obtain a polyamic acid solution with a solid content of 10%. Then, the above solution was poured into the reaction kettle and placed in an oven at 180 degrees Celsius for hydrothermal reaction for 8-10 hours. Take out the reaction kettle, pour out the supernatant, take out the precipitate, wash wit...

Embodiment 2

[0036] In Example 1, the carbonization temperature of the spherical polyimide was changed to 700°C to obtain a spherical polyimide carbon material. The particle size of the material was 5-10 nm. The specific surface area of the material was tested by low-temperature nitrogen adsorption. 130 m surface area 2 / g. The rest of the manufacturing process is the same as in Example 1.

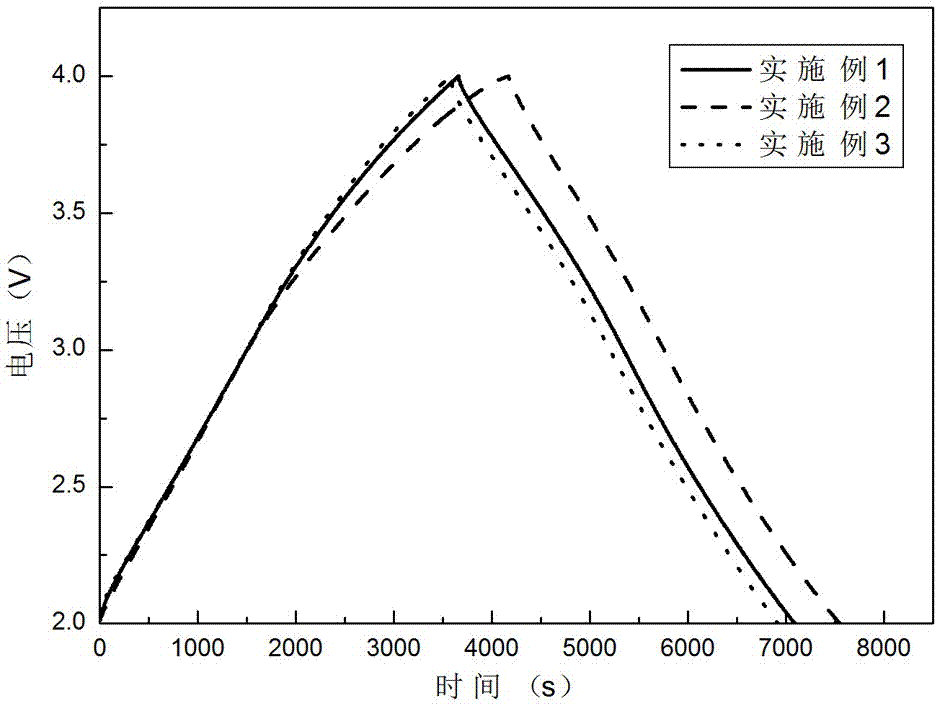

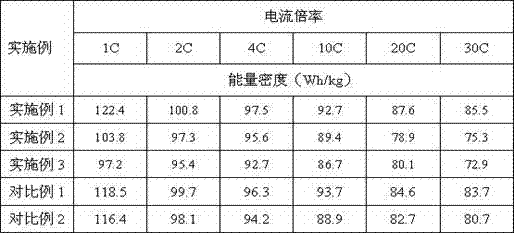

[0037] Lithium-ion capacitor charge and discharge test: After the pre-insertion of lithium is completed, the positive and negative electrodes are formed into a loop, and the 1C rate current is used for charge and discharge. The voltage range is 2~4V. The charge and discharge curves are shown in the attachment. figure 2 , Table 1 shows that the energy density of the lithium-ion capacitor based on the sum of the masses of the two-pole active material is as high as 103.8 Wh / kg under 1C rate current; under 30C rate current, the energy density is 75.3 Wh / kg. After 1500 times of charge and discharge, the ca...

Embodiment 3

[0039] In Example 1, the carbonization temperature of the spherical polyimide was changed to 900°C to obtain a spherical polyimide carbon material. The particle size of the material was 5-10 nm. The specific surface area of the material was tested by low-temperature nitrogen adsorption. Surface area is 135 m 2 / g, the rest of the manufacturing process is the same as in Example 1.

[0040] Lithium-ion capacitor charge and discharge test: After the pre-insertion of lithium is completed, the positive and negative electrodes are formed into a loop, and the 1C rate current is used for charge and discharge. The voltage range is 2~4V. The charge and discharge curves are shown in the attachment. figure 1 , Table 1 shows that the energy density of the lithium ion capacitor based on the sum of the masses of the two-electrode active material is as high as 97.2 Wh / kg under 1C rate current; under 30C rate current, the energy density is 72.9 Wh / kg. After 1500 times of charge and discharge, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com