Stirred bioreactor convertible in flow direction and for artificial liver

A bioreactor and reactor technology, used in suction equipment, dialysis systems, etc., can solve the problems of difficult to form inherent channels, block the bed, and break the microcapsules, and achieve the purpose of maintaining uniform solid-liquid mixing and avoiding pipeline blockage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Preparation of hepatocyte-loaded microcapsules: suspend hepatocytes and 1.5% sodium alginate at a mass concentration of 1×10 7 ~1×10 8 cells / ml, use a high-voltage electrostatic preparation instrument to drop CaCl with a mass concentration of 1.1% 2 In the solution, the formed calcium alginate beads react with 0.05% polylysine solution to form a film.

[0032] Preparation of cell-free microcapsules: the method is as before, 1.5% sodium alginate, and 1.1% CaCl is dripped with a high-voltage electrostatic preparation device 2 In the solution, the formed calcium alginate beads react with 0.05% polylysine solution to form a film.

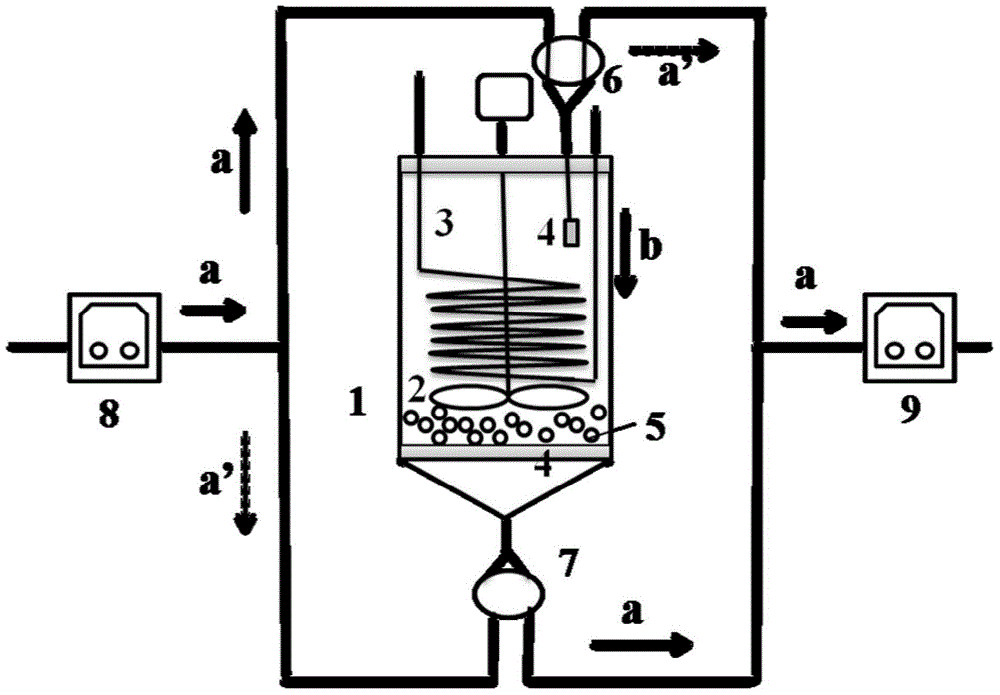

[0033] Main reactor: It is a cylindrical glass reactor, and the inner cavity of the reactor is , The bottom of the reactor is a stainless steel filter with a pore size of 200 mesh.

[0034] Stirring paddle: It is an upper stirring made of polytetrafluoroethylene driven by a motor, and the speed can be adjusted from 0 to 1200rpm. It has two bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com