Processing method for improving gelation ability of shrimp flesh balls

A processing method and technology of shrimp meatballs, applied in the field of food processing, can solve the problems of insufficient gel strength of shrimp meatballs, lack of inherent umami taste of aquatic products, insufficient hardness and elasticity, etc., so as to achieve easy control of process parameters and shorten thawing time , The effect of increasing the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: (preparation of shrimp head protein hydrolyzate)

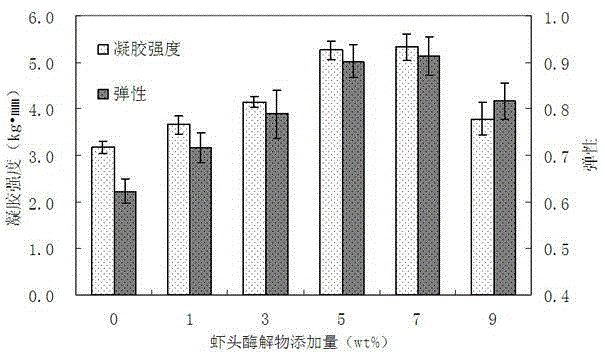

[0027] Fresh or frozen shrimp heads, boiled at 90°C for 30 minutes, crushed with a tissue grinder, homogenized with water, adjusted to pH 8.0 and preheated to 50°C, added Alcalase protease (enzyme activity 100kU / g, Novozymes, Denmark) ) 0.3% (w / w) enzymatic hydrolysis at 50°C for 2h, and then inactivate the enzyme at 90°C for 30min, then lower the temperature to 60°C and adjust the pH to 7.5, add Flavourzyme protease (500MG, Novozymes, Denmark) 0.1% (w / w) Enzyme hydrolysis at 60°C for 4 hours, and then inactivate the enzyme at 90°C for 30 minutes; the hydrolyzate was centrifuged at 6000rpm to remove the precipitate, the supernatant was incubated at 80°C for 10min, and then the fat layer was removed by centrifugation at 8000rpm, followed by electrodialysis to remove salt, Ultrafiltration membrane ultrafiltration (molecular weight cut-off: 30kDa), concentrated by rotary evaporator and then freeze-dried, the ...

Embodiment 2

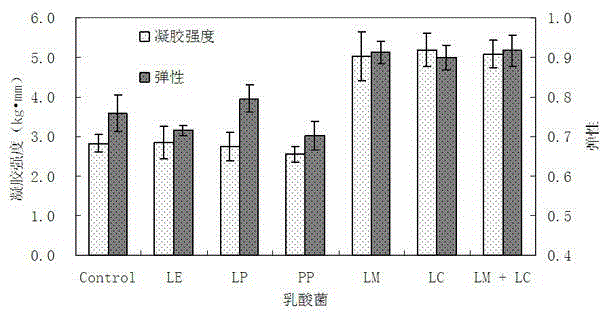

[0029] Put frozen shrimps into plastic cages (cage height ≤ 20cm), the height of the material should not exceed the cage, and then place the cage in a continuous radio frequency thawing machine (the distance between the two electrode plates of the radio frequency thawing machine is 24.5cm, the radio frequency is 27.12MHz, On the conveyor belt with a working power of 7.5kW, turn on the radio frequency thawing machine and thaw for 12~15min. Take 10kg of thawed shrimp, put it in a meat grinder and chop and mix for 1~2min, then add 200g of salt, 300g of glucose and 700g of shrimp head protein hydrolyzate, continue chopping and mixing for 3~5min until the shrimp meat is milky white and sticky. Entering Leuconostoc enterica into the minced shrimp ( Leuconostoc mesenteroides , ATCC 8086) bacterial suspension (with 10 8 ~10 9 CFU / mL), the inoculum size was 2%, mixed evenly, put into a closed stainless steel container and evacuated, and anaerobically fermented at 6°C for 24h. The fe...

Embodiment 3

[0031] Put frozen shrimps into plastic cages (cage height ≤ 20cm), the height of the material should not exceed the cage, and then place the cage in a continuous radio frequency thawing machine (the distance between the two electrode plates of the radio frequency thawing machine is 24.5cm, the radio frequency is 27.12MHz, On the conveyor belt with a working power of 7.5kW, turn on the radio frequency thawing machine and thaw for 12~15min. Take 10kg of thawed shrimp, put it in a meat grinder and chop and mix for 1~2min, then add 300g of salt, 500g of glucose and 500g of shrimp head protein hydrolyzate in turn, continue chopping and mixing for 3~5min until the minced shrimp is milky white and sticky. Introduce Lactobacillus flexus ( Lactobacillus curvatus , ATCC 51436) bacterial suspension (with 10 8 ~10 9 CFU / mL), the inoculum size was 3.5%, mixed evenly, placed in a closed stainless steel container to vacuumize, and anaerobically fermented at 8°C for 18h. The fermented slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com