Physical and chemical wall dissolving method for ganoderma lucidum spore powder

A technology of Ganoderma lucidum spore powder and physical chemistry, which is applied in food science, medical formula, plant raw materials, etc. It can solve the problems of long wall breaking time, low wall breaking rate, and difficulty in removal, and achieves shortened processing time and simple operation method , promote the effect of human body absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

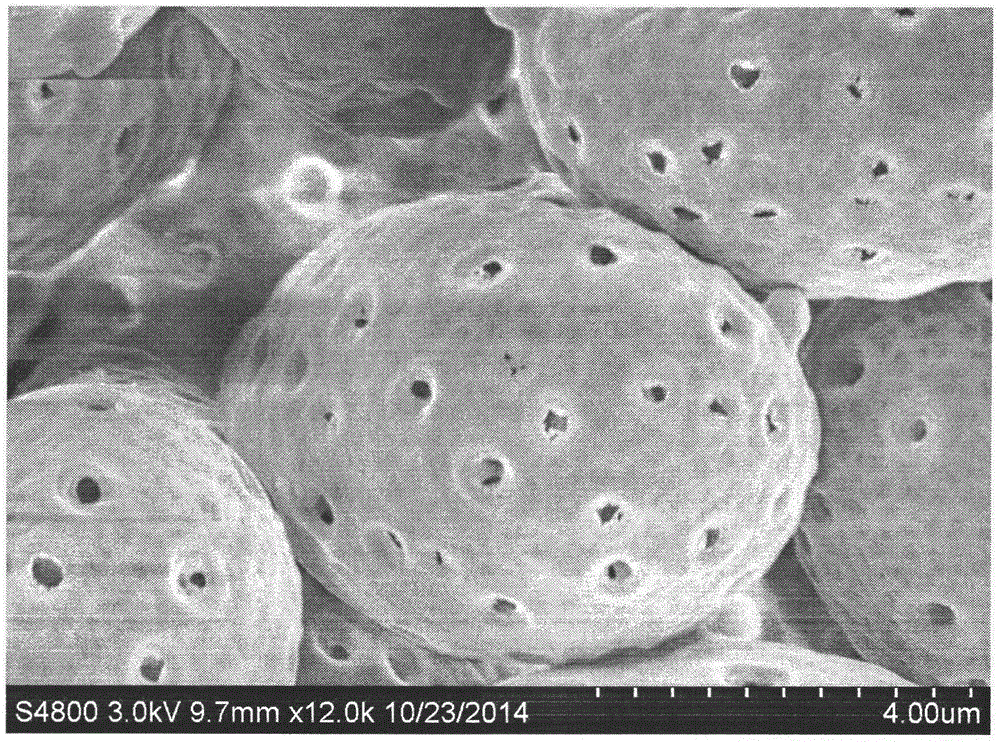

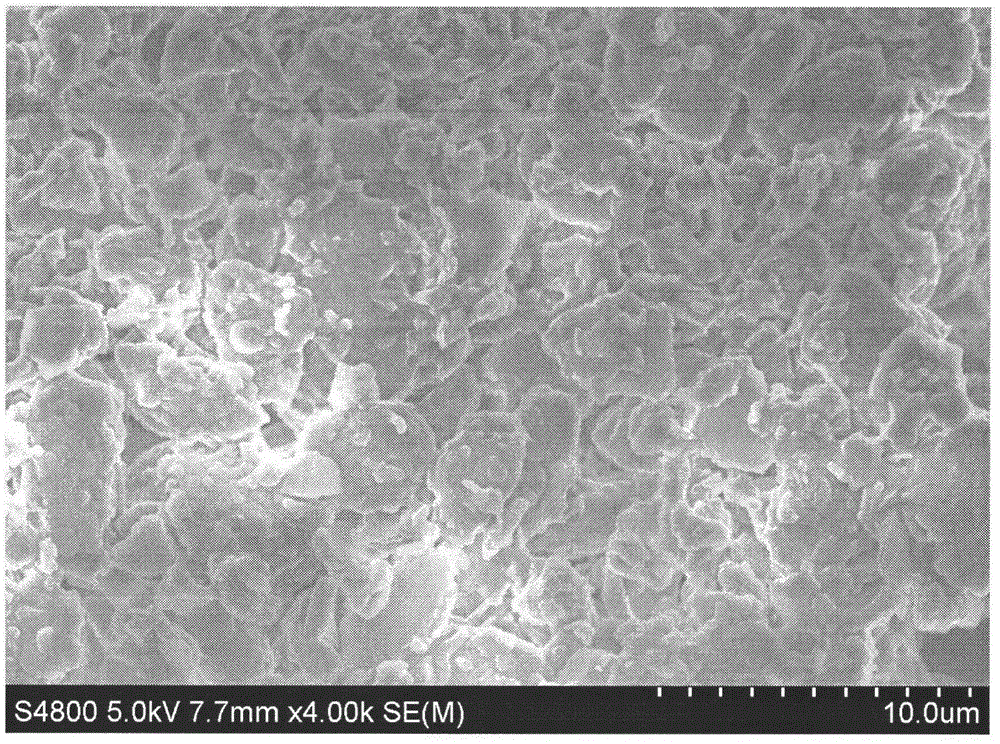

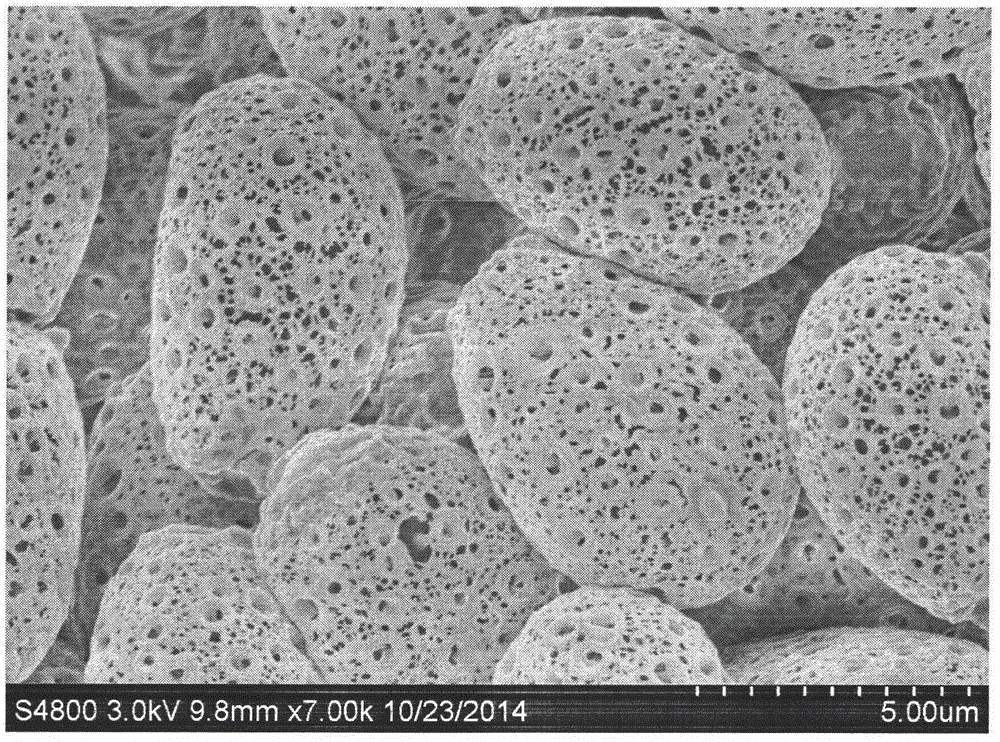

Image

Examples

Embodiment 1

[0024] Weigh 0.5g Ganoderma lucidum spore powder, add 5ml 30% urea solution, sonicate for 20min, freeze at -10°C for 2h, take it out and sonicate again for 10min, add 2.0ml 20% ethanol solution, react at room temperature for 2h, freeze again at -10°C React for 2 hours, then sonicate for 10 minutes, centrifuge to separate the solution, add 1ml 2% ascorbic acid and 1.5ml protective agent solution (containing 0.1% xanthan gum and 6% cyclodextrin) to the obtained solid, stir evenly, and dry to obtain the product.

Embodiment 2

[0026] Weigh 0.5g Ganoderma lucidum spore powder, add 2ml 30% urea solution and 3ml 5% NaCl solution, sonicate for 20min, freeze at -10°C for 2h, then sonicate for 20min, add 5ml 20% ethanol solution, react at room temperature for 1h, -10 Refrigerate and react at ℃ for 1 hour, then sonicate for 20 minutes, centrifuge to separate the solution, add 1ml 2% ascorbic acid and 1.5ml protective agent solution (containing 0.2% guar gum and 5% cyclodextrin) to the obtained solid, stir evenly, Dry the product.

Embodiment 3

[0028] Weigh 0.5g Ganoderma lucidum spore powder, add 5ml 1% sodium hydroxide solution, sonicate for 10min, freeze at -10°C for 2h, take it out and sonicate again for 10min, add 5ml of 20% ethanol solution, freeze for 2h at -10°C, Then sonicate for 10min, add 5ml 30% urea solution, freeze again at -10°C for 2h, sonicate for 10min, centrifuge to separate the solution, add 1.5ml 2% ascorbic acid and 1.5ml protective agent solution (containing 0.1% yellow raw gum and 8% cyclodextrin), stirred evenly, and dried to obtain the product.

[0029] The above percentages are percentages by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com