Nitrogen-sulfur double-doped mesoporous carbon electrode material as well as preparation method and application thereof

An electrode material and mesoporous carbon technology, which is applied in the field of preparation and application of supercapacitor electrode materials, can solve the problems of ineffective utilization of electrolyte ions, limit specific capacitance and electrochemical charge-discharge performance, etc., and achieve improved electron transfer. properties, improve cycle stability, and reduce resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

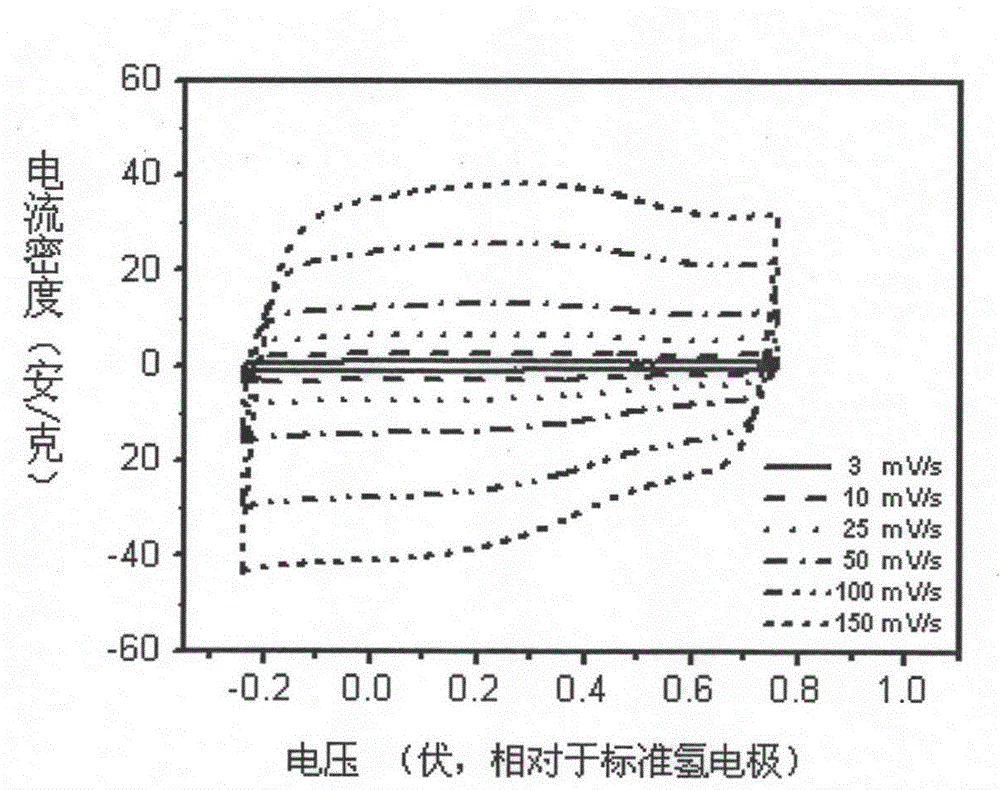

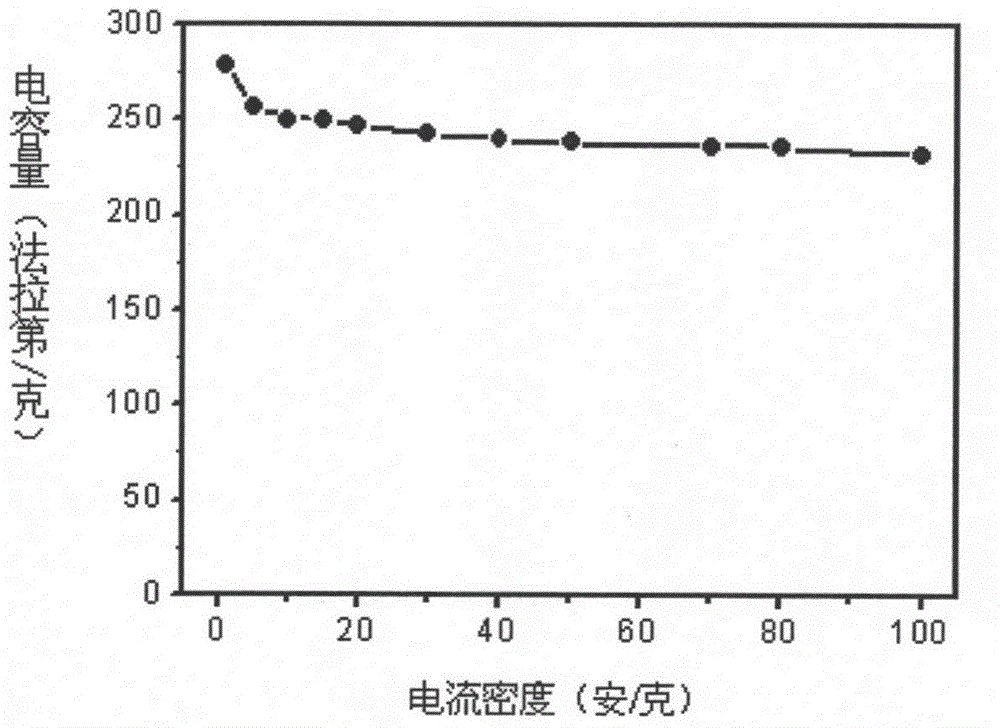

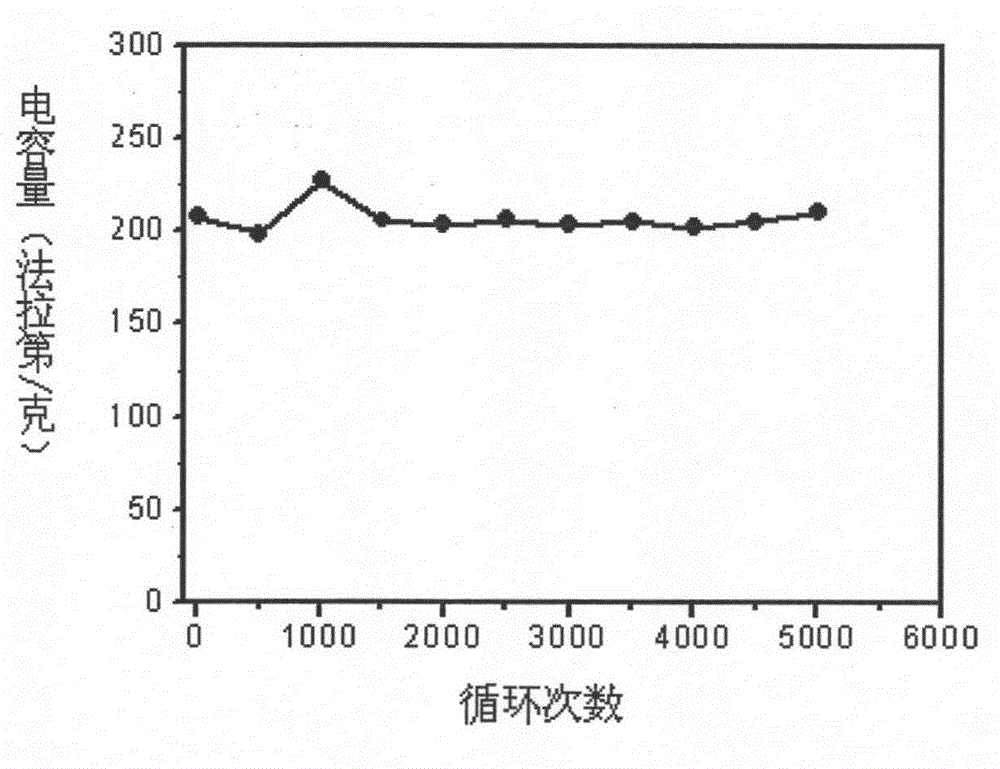

[0033] A kind of nitrogen-sulfur double-doped electrode material, its precursor comprises that the template agent diameter of 46% is the silicon dioxide of 15nm, the nitrogen-containing compound PEI (polyethyleneimine, Sigma-Aldrich ( Shanghai) Trading Co., Ltd., 408700-250ML, Mw=2000) and transition metal salt heptahydrate ferrous sulfate with a mass content of 34% (the above mass content is based on the total mass of the precursor).

[0034] The preparation method of the above-mentioned nitrogen-sulfur double-doped electrode material is as follows: polyethyleneimine and silicon dioxide are formulated into 50% PEI aqueous solution and 20% SiO 2 Aqueous solution, weigh 0.7448g FeSO 4 ·7H 2 O and 0.9 g of 50% PEI in water and combined it with 5 g of 20% SiO 2 The aqueous solution was mixed uniformly under the condition of stirring, and then dried overnight in an oven at 85° C. after ultrasonication for 8 hours, and ground into powder to obtain the precursor. Put the above pr...

Embodiment 2

[0037]A kind of nitrogen-sulfur double-doped electrode material, its precursor comprises that the template agent diameter of 46% is the silicon dioxide of 15nm, the nitrogen-containing compound PEI (polyethyleneimine, Sigma-Aldrich ( Shanghai) Trading Co., Ltd., 408700-250ML, Mw=2000) and transition metal salt heptahydrate ferrous sulfate with a mass content of 34% (the above mass content is based on the total mass of the precursor).

[0038] The preparation method of the above-mentioned nitrogen-sulfur double-doped electrode material is as follows: polyethyleneimine and silicon dioxide are formulated into 50% PEI aqueous solution and 20% SiO 2 Aqueous solution, weigh 0.7448g FeSO 4 ·7H 2 O and 0.9 g of 50% PEI in water and combined it with 5 g of 20% SiO 2 The aqueous solution was mixed uniformly under the condition of stirring, and then dried overnight in an oven at 85° C. after ultrasonication for 8 hours, and ground into powder to obtain the precursor. Put the above pre...

Embodiment 3

[0041] A kind of nitrogen-sulfur double-doped electrode material, its precursor comprises that the template agent diameter of 46% is the silicon dioxide of 15nm, the nitrogen-containing compound PEI (polyethyleneimine, Sigma-Aldrich ( Shanghai) Trading Co., Ltd., 408700-250ML, Mw=2000) and transition metal salt heptahydrate ferrous sulfate with a mass content of 34%. (The above mass content is based on the total mass of the precursor)

[0042] The preparation method of the above-mentioned nitrogen-sulfur double-doped electrode material is as follows: polyethyleneimine and silicon dioxide are formulated into 50% PEI aqueous solution and 20% SiO 2 Aqueous solution, weigh 0.7448g FeSO 4 ·7H 2 O and 0.9 g of 50% PEI in water and combined it with 5 g of 20% SiO 2 The aqueous solution was mixed uniformly under the condition of stirring, and then dried overnight in an oven at 85° C. after ultrasonication for 8 hours, and ground into powder to obtain the precursor. Put the above p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com