Recycling and Utilization Method of Purification and Refining Crystallization Mother Liquor of Long Carbon Chain Dibasic Acid

A long carbon chain dibasic acid and crystallization mother liquor technology, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of hydroxyl compounds, etc., can solve the problem of low recovery rate of long carbon chain dibasic acids and the quality of recycled products Poor, high processing costs and other issues, to achieve the effect of promoting the growth of crystal nuclei, increasing product yield, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

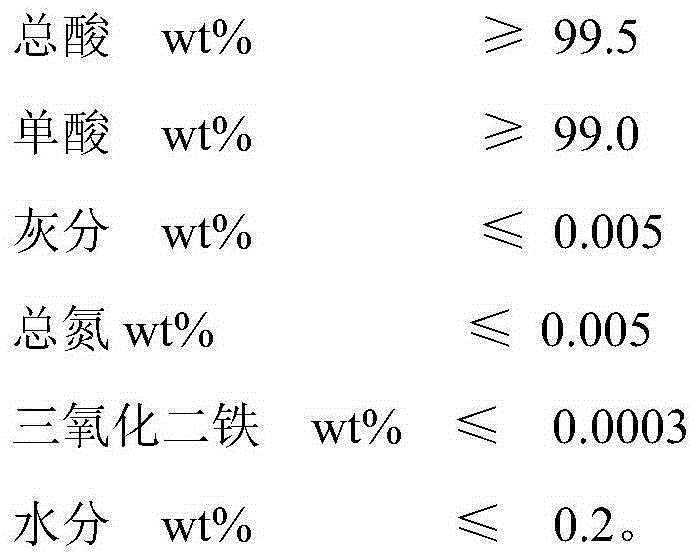

Embodiment 1

[0066] A kind of recycling method of dodecane dibasic acid purification crystallization mother liquor of the present invention comprises the following steps:

[0067] ①. Recycling solvent methanol

[0068] Be that 2000 liters of crystallization mother liquors of 30 grams per liter of dodecane dibasic acid content, drop into the methanol reclaiming distillation still, under stirring, at first add the industrial liquid caustic soda of 30wt%, dodecane dibasic acid: NaOH (mol ratio) =1:2.5, then, heat up distillation, collect and recover methanol, and recycle it for the recrystallization purification process; in the whole process of recovering solvent methanol, use industrial liquid caustic soda to adjust the pH value of the material in the methanol recovery still, and keep the pH ≥8.

[0069] ②. The residual material at the bottom of the distillation tank is dissolved and diluted

[0070] After the recovery of methanol, add water to dissolve the residual material at the bottom ...

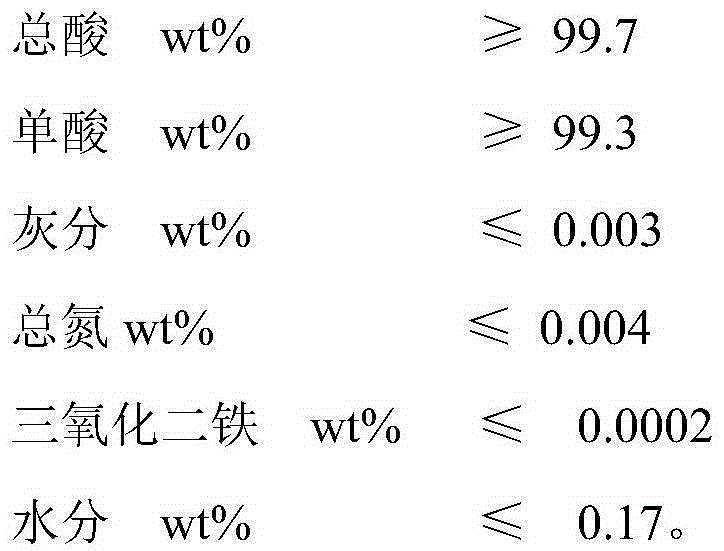

Embodiment 2

[0080] A kind of recycling method of tridecane dibasic acid purification crystallization mother liquor of the present invention comprises the following operation steps:

[0081] ①. Recycling solvent methanol

[0082] Be 2000 liters of crystallization mother liquor with tridecane dibasic acid content of 40 g / liter, drop into methanol and reclaim still kettle, under stirring, at first add the industrial liquid caustic soda of 30wt%, tridecane dibasic acid: NaOH (molar ratio) =1:2.6, then, heat up distillation, collect and recover methanol, and recycle it for the recrystallization purification process; in the whole process of recovering solvent methanol, use industrial liquid alkali to adjust the pH value of the material in the methanol recovery still, and keep the pH ≥8.

[0083] ②. The residual material at the bottom of the distillation tank is dissolved and diluted

[0084] After the recovery of methanol, add water to dissolve the residual material at the bottom of the disti...

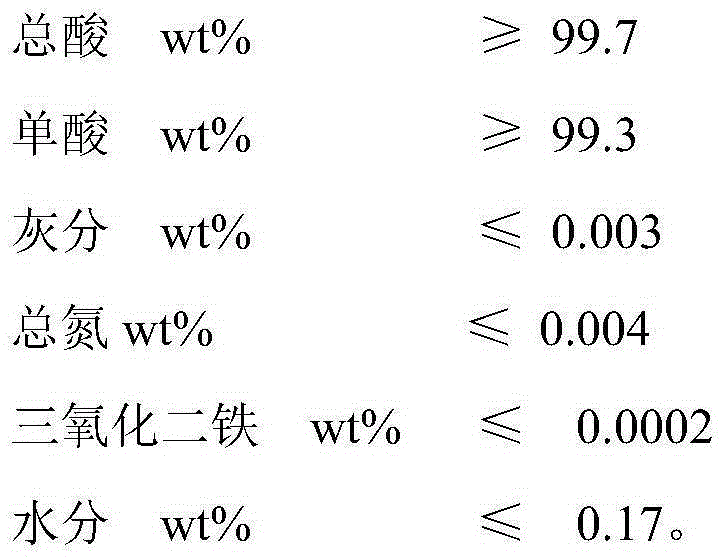

Embodiment 3

[0094] A method for recycling tetradecanedioic acid purification and refining crystallization mother liquor of the present invention comprises the following steps:

[0095] ①. Recycling solvent methanol

[0096] Be 2000 liters of crystallization mother liquors with tetradecane dibasic acid content of 50 grams per liter, drop into methanol reclaiming distillation still, under stirring, at first add the industrial liquid caustic soda of 30wt%, tetradecane dibasic acid: NaOH (molar ratio) =1:2.7, then, heat up distillation, collect and recover methanol, and recycle it for the recrystallization purification process; in the whole process of recovering solvent methanol, use industrial liquid caustic soda to adjust the pH value of the material in the methanol recovery distillation kettle, and always maintain the pH ≥8.

[0097] ②. The residual material at the bottom of the distillation tank is dissolved and diluted

[0098] After the recovery of methanol, water is added to dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com