Copper-doped lattice strain quantum dots and preparation method thereof

A lattice strain, quantum dot technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of large particle size quantum dots that are not very practical, and the fluorescence emission wavelength can be adjusted to a small extent. To achieve the effect of simple method, good monodispersity and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

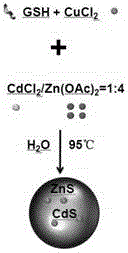

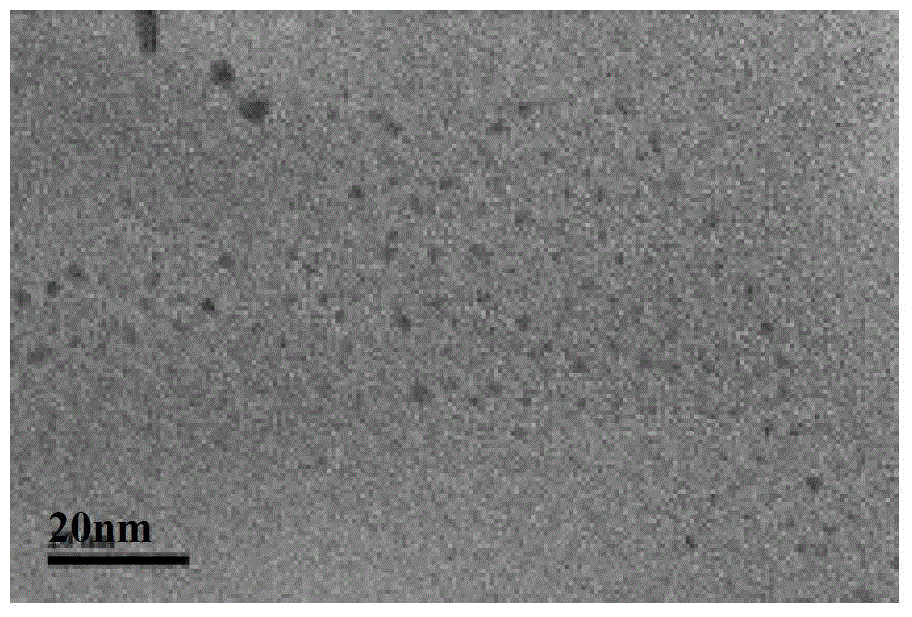

[0029] In this embodiment, a method for preparing copper-doped lattice-strained quantum dots comprises the following steps:

[0030] (1) Precursor stock solution A: Weigh 0.183g of anhydrous cadmium chloride and dissolve it in 10ml of ultrapure water;

[0031] (2) Precursor stock solution B: Weigh 0.183g of anhydrous zinc acetate and dissolve it in 10ml of ultrapure water;

[0032] (3) Precursor stock solution C: Weigh 0.175g of copper chloride dihydrate and dissolve in 10ml of ultrapure water;

[0033] (4) Precursor stock solution D: Weigh 0.123g of reduced glutathione and dissolve it in 10ml of ultrapure water;

[0034] (5) Take 0.4ml of precursor stock solution A, add 0.6ml of precursor stock solution B correspondingly, add 0.01ml of precursor stock solution C, 5ml of precursor stock solution D, and dilute to 100ml (anhydrous cadmium chloride, The molar ratio of anhydrous zinc acetate, copper chloride dihydrate and glutathione is 1:1.5:0.025:5);

[0035] (6) Adjust the p...

Embodiment 2

[0040] In this embodiment, a method for preparing copper-doped lattice-strained quantum dots comprises the following steps:

[0041] (1) Precursor stock solution A: Weigh 0.183g of anhydrous cadmium chloride and dissolve it in 10ml of ultrapure water;

[0042] (2) Precursor stock solution B: Weigh 0.183g of anhydrous zinc acetate and dissolve it in 10ml of ultrapure water;

[0043] (3) Precursor stock solution C: Weigh 0.175g of copper chloride dihydrate and dissolve in 10ml of ultrapure water;

[0044] (4) Precursor stock solution D: Weigh 0.123g of reduced glutathione and dissolve it in 10ml of ultrapure water;

[0045] (5) Take 0.2ml of precursor stock solution A, add 0.8ml of precursor stock solution B correspondingly, add 0.01ml of precursor stock solution C, 5ml of precursor stock solution D, and dilute to 100ml (anhydrous cadmium chloride, The molar ratio of anhydrous zinc acetate, copper chloride dihydrate and glutathione is 1:4:0.05:10);

[0046] (6) Adjust the pH ...

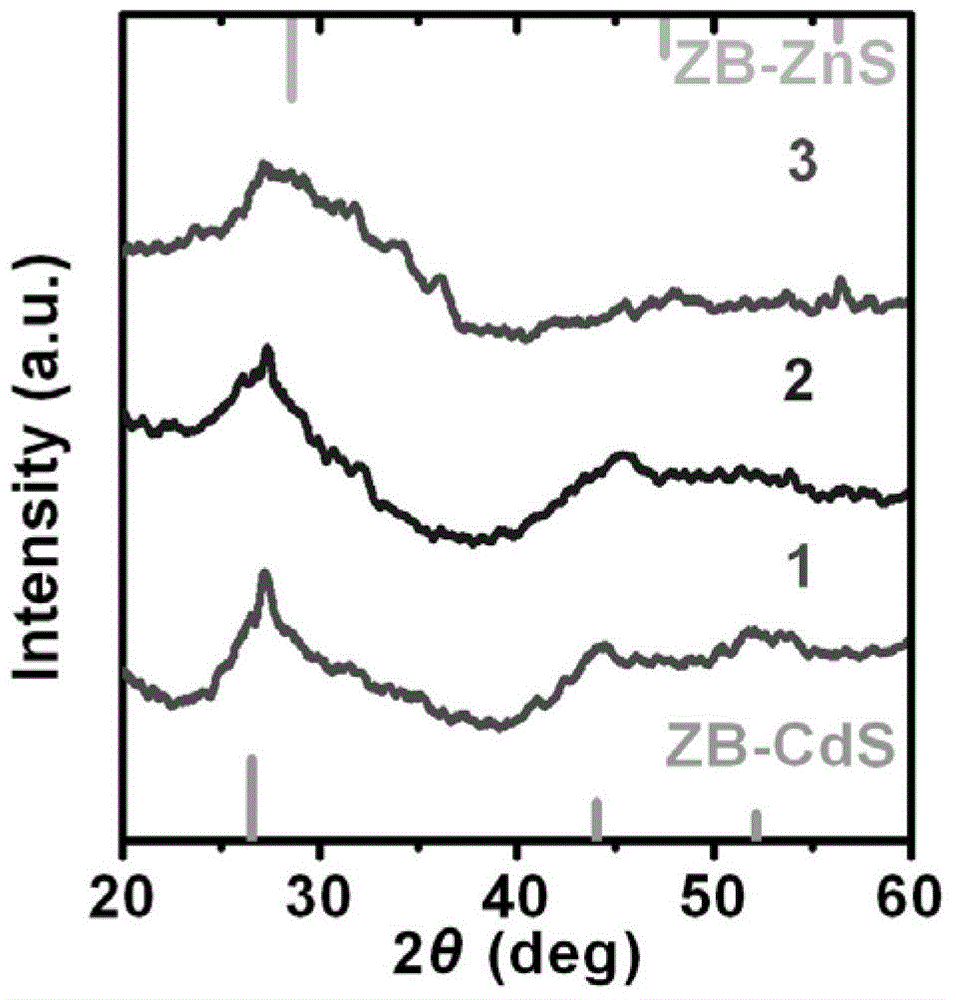

Embodiment 3

[0051] In this embodiment, a method for preparing copper-doped lattice-strained quantum dots comprises the following steps:

[0052] (1) Precursor stock solution A: Weigh 0.183g of anhydrous cadmium chloride and dissolve it in 10ml of ultrapure water;

[0053] (2) Precursor stock solution B: Weigh 0.183g of anhydrous zinc acetate and dissolve it in 10ml of ultrapure water;

[0054] (3) Precursor stock solution C: Weigh 0.175g of copper chloride dihydrate and dissolve in 10ml of ultrapure water;

[0055] (4) Precursor stock solution D: Weigh 0.123g of reduced glutathione and dissolve it in 10ml of ultrapure water;

[0056] (5) Take 0.2ml of precursor stock solution A, add 0.8ml of precursor stock solution B correspondingly, add 0.01ml of precursor stock solution C, 5ml of precursor stock solution D, and dilute to 100ml (anhydrous cadmium chloride, The molar ratio of anhydrous zinc acetate, copper chloride dihydrate and glutathione is 1:4:0.05:10);

[0057](6) Adjust the pH v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com