Lubricant composition for adiabatic gasoline engine

A lubricant composition and gasoline engine technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems such as the lack of unified gasoline engine oil quality specifications, achieve good high-temperature oxidation stability, and inhibit polar substances such as sludge Formation, good effect of low temperature startability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] It is formed by blending the following components in mass percentage:

[0021] components

Embodiment 2

[0023] It is formed by blending the following components in mass percentage:

[0024] components

Embodiment 3

[0026] It is formed by blending the following components in mass percentage:

[0027] components

Content (mass percentage)

Combination of 45% polyperfluoroalkyl ether and 55% oil-soluble polyether by mass

71.492%

Composite of 45% low base value synthetic calcium sulfonate and 55% high base value synthetic calcium sulfonate

7.0%

Compound of 45% polyisobutylene bis-succinimide and 55% dienyl succinimide by mass

7.0%

Phosphobisoctyl basic zinc salt

0.9%

2-Mercaptobenzimidazole compounded with 55% N-phenyl-α-aniline with a mass ratio of 45%

1.0%

Benzotriazole derivatives

1.2%

Sulfated calcium alkylphenate

2.5%

0.008%

Alkyl phosphite

2.5%

Compound of 45% benzotriazole and 55% sodium petroleum sulfonate by mass

1.5%

Copper dialkyldithiocarbamate

0.9%

4.0%

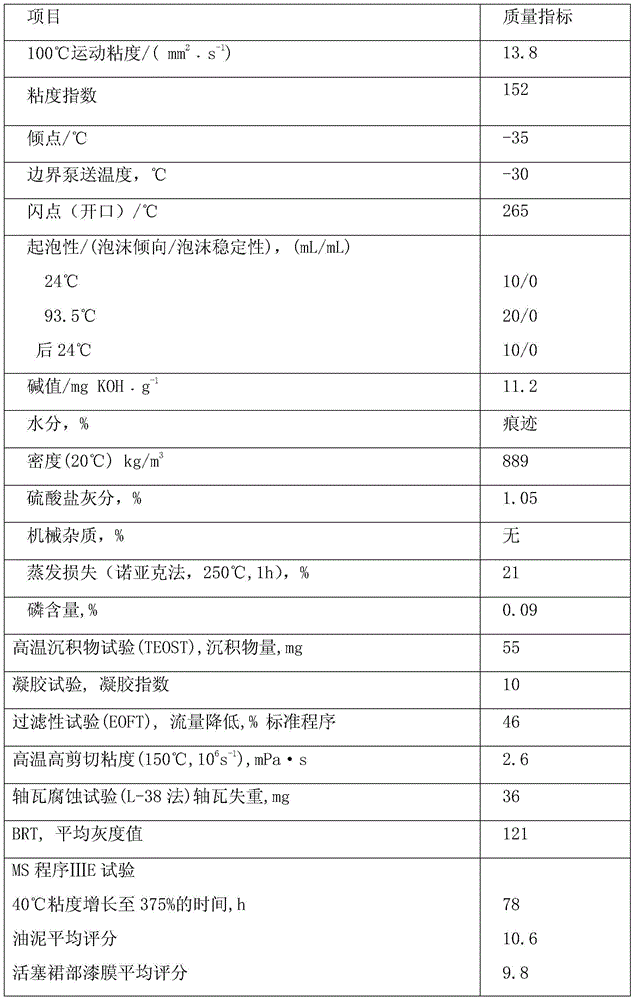

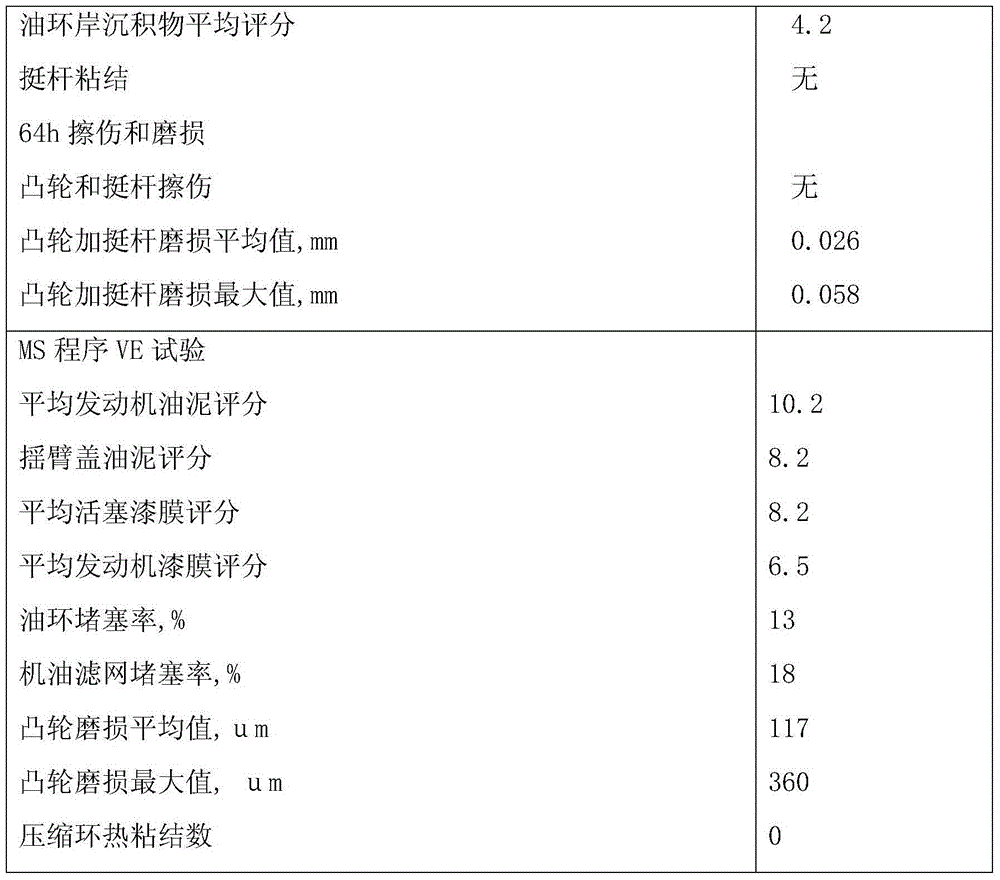

[0028] The main technical index of embodiment 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com