Ionic-liquid-coated lithium ion battery positive plate as well as preparation method thereof and lithium ion battery

A lithium-ion battery and ionic liquid technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of high viscosity of ionic liquid, large amount of electrolyte solution, high cost, etc., to improve specific capacity, production The effect of low cost and high specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

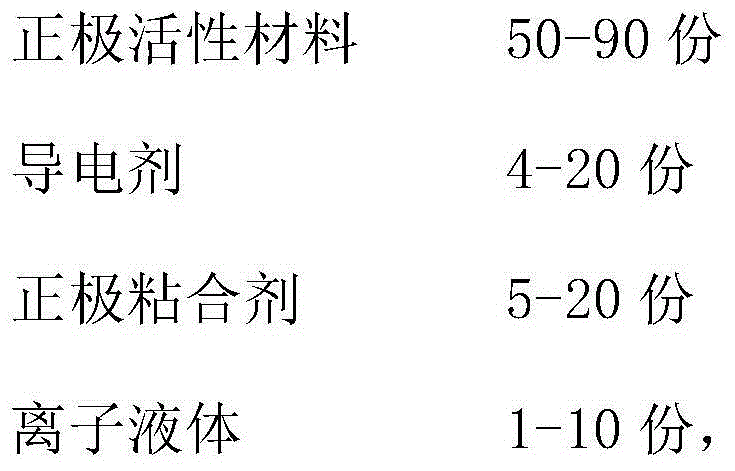

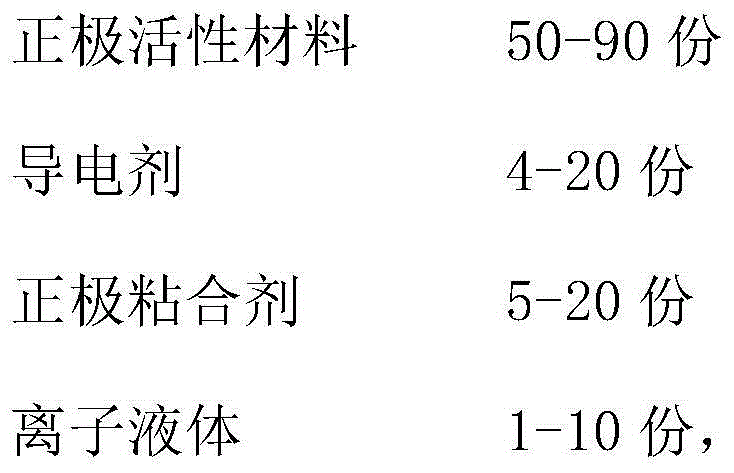

Method used

Image

Examples

Embodiment 1

[0030] An ionic liquid-coated lithium-ion battery positive electrode sheet, including: 85 parts of lithium iron phosphate, 6 parts of acetylene black, 8 parts of polyvinylidene fluoride, ionic liquid 1-ethyl-3-methylimidazolium tetrafluoroborate 1 part and 100 parts of solvent N-methylpyrrolidone.

[0031] A preparation method of a lithium-ion battery positive plate coated with an ionic liquid, comprising the following steps:

[0032] Mix and grind 85 parts of lithium iron phosphate, 6 parts of acetylene black, 8 parts of polyvinylidene fluoride, and 1 part of ionic liquid 1-ethyl-3-methylimidazolium tetrafluoroborate, and then add solvent N- Stir 100 parts of methylpyrrolidone to make a positive electrode slurry, apply the slurry to both sides of an aluminum foil, dry it at 110°C, and roll it to obtain a positive electrode sheet.

[0033] A kind of lithium ion battery, its preparation process is:

[0034] 92.5 parts of graphite, 3.5 parts of sodium carboxymethyl cellulose, ...

Embodiment 2

[0036] An ionic liquid-coated lithium-ion battery positive electrode sheet, comprising: 83.8 parts of lithium cobaltate, 7 parts of acetylene black, 8 parts of polytetrafluoroethylene, ionic liquid 1-butyl-3-methylimidazole trifluoromethanesulfonic acid 1.2 parts of salt and 100 parts of solvent dimethylamide.

[0037] A preparation method of a lithium-ion battery positive plate coated with an ionic liquid, comprising the following steps:

[0038] 83.8 parts of lithium cobaltate, 7 parts of acetylene black, 8 parts of polytetrafluoroethylene, and 1.2 parts of ionic liquid 1-butyl-3-methylimidazolium trifluoromethanesulfonate are mixed and ground, dried, and then the solvent dimethyl 100 parts of the amide were stirred to make a positive electrode slurry, and the slurry was coated on both sides of an aluminum foil, dried at 110° C., and rolled to obtain a positive electrode sheet.

[0039] A kind of lithium ion battery, its preparation process is:

[0040] 87 parts of graphit...

Embodiment 3

[0042]An ionic liquid-coated lithium ion battery positive electrode sheet, comprising: 82.5 parts of lithium manganate, 7 parts of acetylene black, 9 parts of polyvinylidene fluoride, 1.5 parts of ionic liquid N-butylpyridine tetrafluoroborate and solvent two 90 parts of methylamide.

[0043] A preparation method of a lithium-ion battery positive plate coated with an ionic liquid, comprising the following steps:

[0044] Mix 82.5 parts of lithium manganate, 7 parts of acetylene black, 9 parts of polyvinylidene fluoride, and 1.5 parts of ionic liquid N-butylpyridine tetrafluoroborate, mix and grind, dry, and then add 90% of solvent dimethylamide to carry out Stir to make a positive electrode slurry, apply the slurry to both sides of the aluminum foil, dry at 110°C, and roll to obtain a positive electrode sheet.

[0045] A kind of lithium ion battery, its preparation process is:

[0046] 88 parts of graphite, 6.5 parts of sodium carboxymethyl cellulose, 5.5 parts of negative e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com