Carbon fluoride composite positive electrode and preparation method thereof

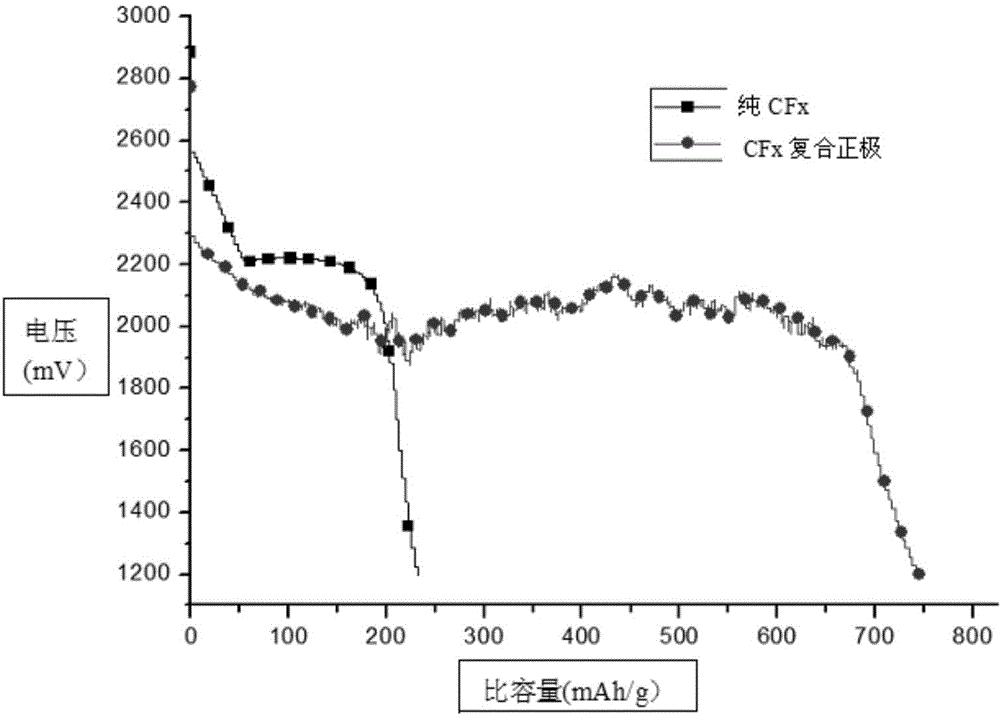

A composite positive electrode, carbon fluoride technology, applied in the direction of primary battery electrodes, battery electrodes, electrical components, etc., can solve the problems of not significantly improving the discharge platform of lithium fluoride carbon batteries, uneven dispersion of CFx, etc., to reduce hydrophilicity and hydrophilicity. The effect of poor oiliness, high current efficiency and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

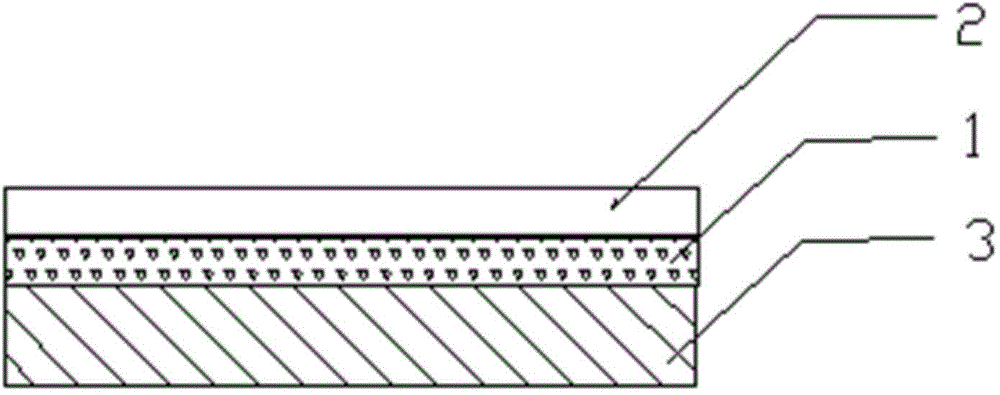

[0049] Pure aluminum foil with a thickness of 0.01 mm is used as the substrate, fluorinated graphite with a fluorocarbon atomic ratio of 1.03 and a particle size of 5-10 μm is used as the raw material, carbon nanotubes are used as the carbon conductive agent, and polyvinylidene fluoride is used as the binder. The integrated carbon fluoride positive electrode is prepared by the following process:

[0050] (1) Clean fluorocarbon and carbon conductive agent

[0051]Add fluorinated graphite and carbon conductive agent to the mixed solution of ethanol and water with a volume ratio of 1:1, and wash under the condition of temperature of 40°C and stirring speed of 200 rpm, with the oscillating frequency of 30kHz ultrasonic wave 10min;

[0052] (2) Preparation of composite coating

[0053] After the fluorinated graphite and carbon conductive agent washed in step (1) are uniformly mixed with the binder, they are added to N-methylpyrrolidone (NMP) and stirred for 6 hours at a stirring ...

Embodiment 2

[0068] Pure aluminum foil with a thickness of 0.02mm is used as the substrate, fluorinated carbon nanotubes with a fluorocarbon ratio of 0.85 and a particle size of 10-15 μm are used as raw materials, acetylene black is used as a carbon conductive agent, and polyvinylidene fluoride is used as a binder. The integrated carbon fluoride positive electrode is prepared by the following process:

[0069] (1) Clean fluorocarbon and carbon conductive agent

[0070] Add fluorinated carbon nanotubes and carbon conductive agent to the mixed solution of ethanol and water with a volume ratio of 1:2. Under the condition of temperature of 40°C and stirring speed of 200 rpm, the ultrasonic wave was assisted by an oscillation frequency of 30kHz. Wash for 10 minutes;

[0071] (2) Preparation of composite coating

[0072] After mixing the fluorinated carbon nanotubes and carbon conductive agent and the binder after step (1) washing, they were added to N-methylpyrrolidone (NMP) and stirred for 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com