Method for reactivating used hydrogenation treatment titania catalyst, and regenerated hydrogenation treatment titania catalyst

A titanium dioxide and catalyst technology, which is applied in the field of regenerating titanium dioxide catalysts for hydroprocessing, can solve problems such as unfavorable economic aspects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

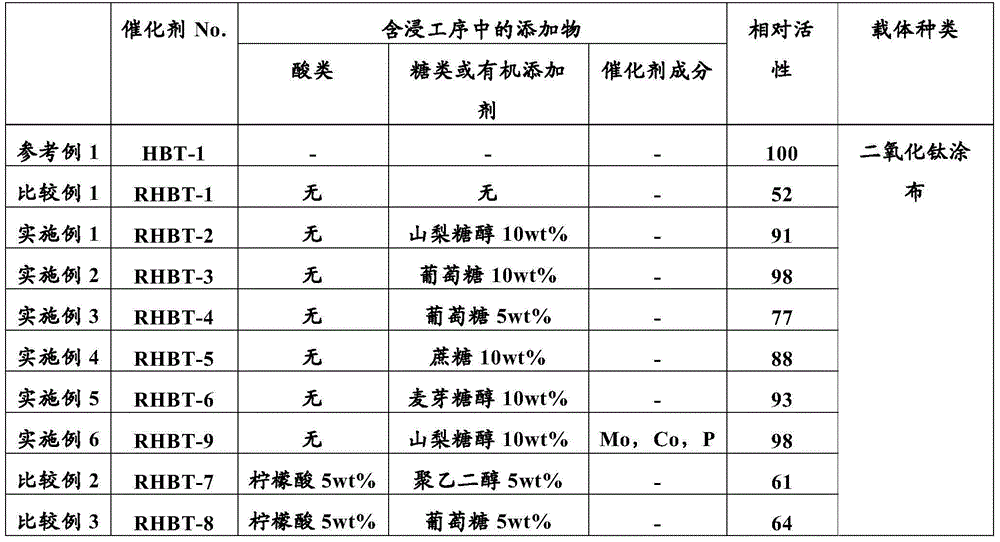

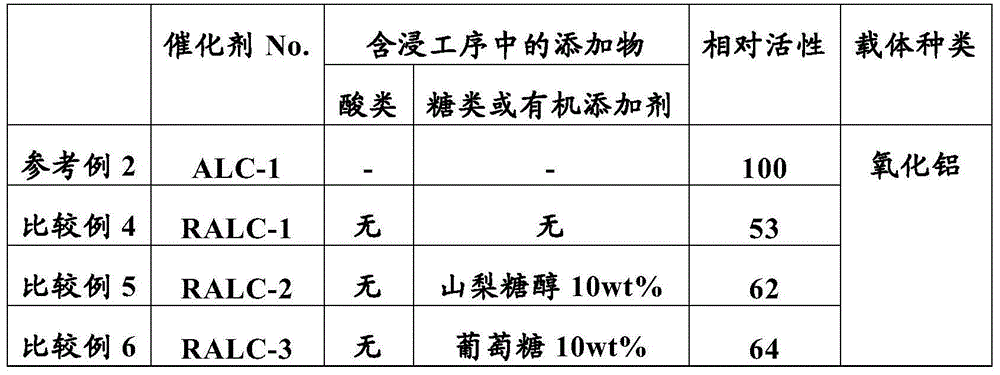

Examples

preparation example Construction

[0082] [Preparation of Titanium Dioxide Catalyst for Hydrotreating]

[0083]

[0084] Prepare the whole amount of raw material liquid required for the operation of the following instructions respectively: A liquid formed by adding water in a ratio of 1030g to 970g of aluminum chloride hexahydrate; The B liquid that is formed, is 16.6 mass % at Ti concentration, and Cl concentration is 32.3 mass % titanium tetrachloride solution 198g, add water to make 1.8 liters (L) of C liquid, and add water to 14% ammonia water 231g 1.8 L of liquid D was prepared, and liquid E was obtained by adding 733 g of hydrochloric acid and 13 g of water to 1520 g of a titanium tetrachloride solution having a Ti concentration of 16.7% by mass and a Cl concentration of 32.6% by mass.

reference example 1

[0086]

[0087] (a) Put 14 liters of water in a 19 L enamel container, and heat to 80° C. while stirring. 850 g of liquid A was added to this enamel container and kept for 5 minutes. The pH of the liquid at this time (hereinafter referred to as "synthesis solution") was 2.5. Next, liquid B in an amount to bring the pH of the synthesis solution to 7.5 was added to the enamel container and kept for 5 minutes (the number of pH swings was the first time).

[0088] (b) Then, add 850 g of A solution, adjust the pH of the synthetic solution to 3.0 and keep it for 5 minutes, then add the B solution that makes the pH of the synthetic solution reach 7.5, and keep it for 5 minutes (the second time of pH swing).

[0089] (c) Next, chloride ions and ammonium ions which are inclusions are washed and removed to obtain alumina hydrate particles with a pH swing of 2 times.

[0090]

[0091] 122 g of the above-obtained alumina hydrate particles were collected on an oxide basis, and stirre...

Embodiment 1

[0102] The used hydrotreating titanium dioxide catalyst HBT-1 recovered from the gas oil hydrodesulfurization unit operated for about one year was cleaned with toluene solvent, and then dried at 120° C. for 10 hours in an air atmosphere to remove the solvent. The catalyst at this time contained 14.7 wt% of carbon components and 8.5 wt% of sulfur components.

[0103] While rotating the dried catalyst in the rotary kiln, the low oxygen concentration gas with the oxygen concentration adjusted to 2.0% was circulated in the furnace by diluting the air with nitrogen, and at the same time, the temperature in the furnace was kept at 350° C. After maintaining for 3 hours, the temperature was gradually increased, and the temperature was maintained at 500° C. for 3 hours to perform a coke removal treatment (coke removal step). The calcined catalyst contained 0.87% of carbon components and 0.62% of sulfur components. The catalyst after the coke removal treatment was referred to as RHBT-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com