Method for preparing structure and performance controllable super nanofiltration membrane

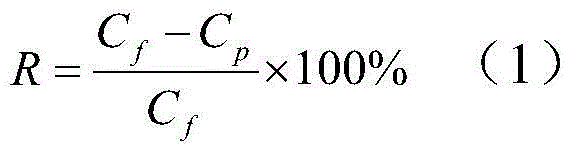

A nanofiltration membrane and ultrafiltration membrane technology, applied in the field of new nanofiltration membrane separation, can solve the problems of inability to achieve anti-pollution and permeation performance, membrane flux decline, desalination layer shedding, etc. Inexpensive and readily available, hydrophilicity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Soak the polysulfone ultrafiltration base membrane in a solution of 1% sodium lauryl sulfate for 4 hours, and then wash it with pure water; prepare a humectant triethylamine with a mass fraction of 0.1% of piperazine and a mass fraction of 0.3% Aqueous solution of amine camphorsulfonate, stirred evenly; prepare 0.08wt% n-hexane solution of polyfunctional acid chloride. Fix the polysulfone ultrafiltration membrane (molecular weight cut off about 68,000) on a glass plate, then pour a certain volume of aqueous phase solution into the surface of the ultrafiltration membrane, leave it for 10 seconds, then pour out the aqueous phase solution, and then pour the The water phase on the surface of the membrane is dried, so that the surface of the porous support is evenly attached to the solute of the amino or hydroxyl compound, and then a certain volume of the oil phase solution is poured into the membrane surface, and after standing for 10 seconds, the oil phase is poured out and...

Embodiment 2

[0036] It is the aqueous phase solution of the humectant triethylamine camphorsulfonate that the massfraction is 0.3% that the piperazine that configuration contains massfraction, the polyester polyol of 0.1% and massfraction are 0.3%, other operation steps are with embodiment 1.

Embodiment 3

[0038] It is the aqueous phase solution of the humectant triethylamine camphorsulfonate that the mass fraction is 0.3% that the piperazine that configuration contains mass fraction is 0.1%, the polyester diol that mass fraction is 0.1% and mass fraction, other operation steps are with embodiment 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com