Nickel iridium-oxide composite catalyst and preparation method thereof

A composite catalyst and oxide technology, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. It can solve the problems of poor purity of nickel-iridium alloy and influence on catalytic effect, etc. , to achieve the effect of low cost, uniform distribution of components, and controllable catalyst components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

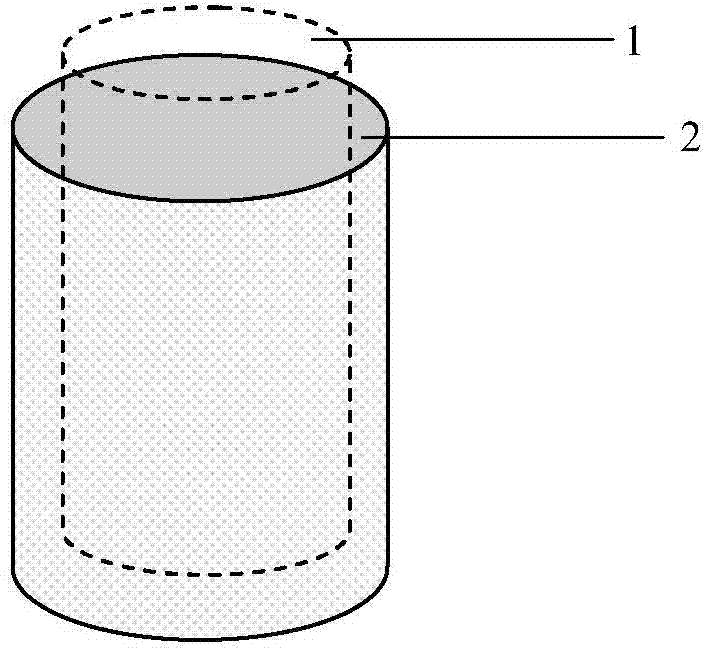

[0023] Such as figure 1 As shown, a circular 304 stainless steel wire mesh with a mesh diameter of 5 microns is used, and its diameter is 1.5 cm. figure 2 In 1 is a stainless steel frame, 2 is an electrochemically deposited nickel-iridium oxide catalyst film layer. First configure 50mL electroplating solution of iridium trichloride 0.010mol / L, nickel sulfate 0.045mol / L, nickel sulfamate 0.05mol / L, citric acid 0.225mol / L, cerium oxide 15g / L, saccharin 0.008mol / L, The weighed medicine is introduced into a 50mL glass container. First add about 25mL of ionized water to stir and dissolve; then add dropwise sodium hydroxide solution to adjust the pH to around 4.0, then add deionized water to 50mL, measure the pH of the plating solution with a pH meter, and then add a small amount Sodium hydroxide fine-tune the pH to 5.0. The workpiece uses stainless steel wire mesh, and the surface is cleaned with detergent first, then pickled for 2 minutes, and then cleaned with acetone ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com