High-temperature resistant rubber conveyer belt and preparation method thereof

A conveyor belt and high-temperature-resistant technology, which is applied in the field of high-temperature-resistant rubber conveyor belts and its preparation, can solve the problems of unmentioned bonding method between covering rubber and skeleton materials, poor co-vulcanization performance of silicone rubber and EPDM rubber, etc. , to achieve the effects of simple structure, improved service life, and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

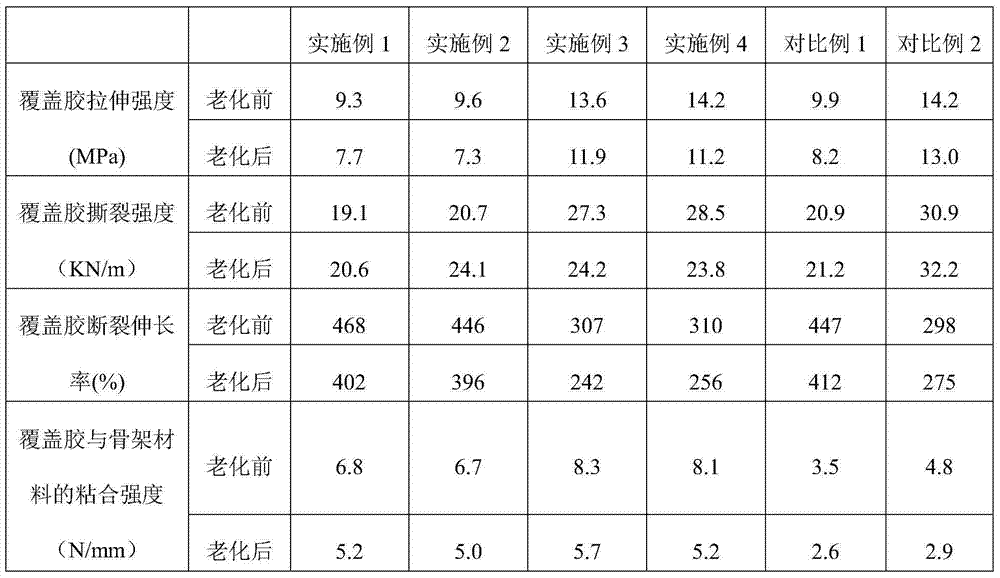

Examples

Embodiment 1

[0017] On the double-roll mill, add 100 parts of silicone rubber, control the roller temperature of the mill at 30-50°C, add 40 parts of fumed white carbon black, 15 parts of activated magnesium oxide (commercially available), N, N'- 8 parts of m-phenylene bismaleimide, 1.5 parts of adhesive RA, 1.5 parts of adhesive RS, and finally add 0.3 parts of crosslinking agent di-tert-butyl peroxide and 5 parts of triallyl cyanurate . Control the roller temperature of the mill between 45-70°C, mix evenly on the mill, then adjust the roller distance of the mill to 0.5-1 mm, roll temperature 40-50°C, thin pass more than 5 times to obtain the final rubber stand-by. Put the above final blended rubber into the open mill for re-milling, and then put it in the calender for calendering to release the sheet for use. The thickness of the film is controlled at 3-12mm when calendering the sheet. The film is tightly bonded with untreated polyester canvas on a forming machine (model DCY-1800, Wuxi...

Embodiment 2

[0019] On the double-roll mill, add 100 parts of silicone rubber, control the roller temperature of the mill at 30-50°C, add 40 parts of fumed white carbon black, 3 parts of nano-zinc oxide, N,N'-m-phenylene bis 12 parts of maleimide, 1.5 parts of adhesive A, 1.5 parts of adhesive RE, and finally 1.5 parts of crosslinking agent dicumyl peroxide (DCP) and 2.5 parts of triallyl cyanurate . Control the roller temperature of the mill between 45-70°C, mix evenly on the mill, then adjust the roller distance of the mill to 0.5-1 mm, roll temperature 40-50°C, thin pass more than 5 times to obtain the final rubber stand-by. Put the above final blended rubber into the open mill for re-milling, and then put it in the calender for calendering to release the sheet for use. The thickness of the film is controlled at 3-12mm when calendering the sheet. On the forming machine, the film is tightly bonded with the untreated aramid canvas to form a blank for a high-temperature resistant conveyo...

Embodiment 3

[0021] On the double-roll mill, add 100 parts of fluororubber, control the temperature of the rollers of the mill at 30-50°C, add 5 parts of nano-calcium oxide, 40 parts of thermal carbon black N990, N,N'-4,4' - 2.5 parts of diphenylmethane bismaleimide (BMI), 1.25 parts of adhesive RA, 1.25 parts of adhesive RK, and finally add cross-linking agent and cross-linking auxiliary agent: dicumyl peroxide (DCP) 3 parts, 2 parts of triallyl isocyanurate (TAIC). Control the roller temperature of the mill between 45-70°C, mix evenly on the mill, then adjust the roller distance of the mill to 0.5-1 mm, roll temperature 40-50°C, thin pass more than 5 times to obtain the final rubber stand-by. Put the above final blended rubber into the screw extruder or open mill for re-milling, and then put it in the calender for calendering to release the sheet for use. When calendering the sheet, the thickness of the film is controlled at 3-12mm. On the forming machine, the film is closely bonded wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com