Surfactant assisted in situ co-precipitation method for preparing core-shell structure nano powder

A surfactant, in-situ co-precipitation technology, applied in the chemical industry, can solve the problems of low interface bonding strength, large extrinsic loss, uneven distribution, etc., and achieve the effects of low cost, uniform particle size and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Dissolve a portion of 0.05mol of barium nitrate, 0.05mol of strontium nitrate and 0.1mol of magnesium nitrate in 200ml of deionized water, stir well to obtain a solution containing Ba, Sr and Mg;

[0026] 2) Dissolve 0.2mol oxalic acid in 200ml ethanol and stir evenly to obtain an oxalic acid-ethanol solution;

[0027] 3) Dissolve a portion of 0.1mol butyl titanate in the above oxalic acid-ethanol solution and stir evenly to obtain a titanium oxalate solution;

[0028] 4) Dissolve a portion of 0.0263mol (10ml) oleic acid in 50ml ethanol solution, and stir evenly at a temperature of 60°C to obtain a surfactant solution;

[0029] 5) Mix and stir the solution containing Ba, Sr, Mg obtained above, the solution containing Ti, and the surfactant solution, and then slowly add ammonia water to adjust its pH=2 to obtain oleic acid-modified Ba 0.5 Sr 0.5 TiO 3 MgO precursor solution;

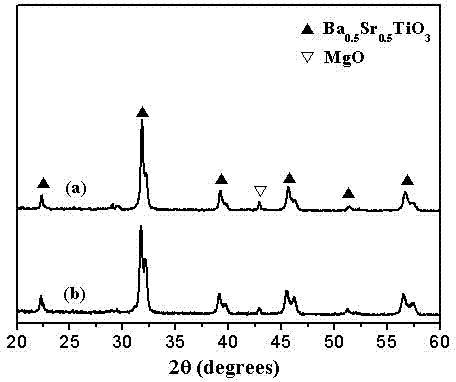

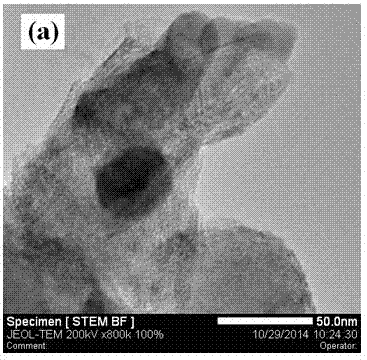

[0030] 6) Add the above Ba 0.5 Sr 0.5 TiO 3 The MgO precursor solution was subjected ...

Embodiment 2

[0034] 1) Dissolve a portion of 0.05mol of barium nitrate, 0.05mol of strontium nitrate and 0.1mol of magnesium nitrate in 200ml of deionized water, stir well to obtain a solution containing Ba, Sr and Mg;

[0035] 2) Dissolve 0.2mol oxalic acid in 200ml ethanol and stir evenly to obtain an oxalic acid-ethanol solution;

[0036] 3) Dissolve a portion of 0.1mol butyl titanate in the above oxalic acid-ethanol solution and stir evenly to obtain a titanium oxalate solution;

[0037] 4) Dissolve a portion of 0.0367mol (10g) sodium dodecylsulfonate in 50ml of deionized water, and stir evenly at a temperature of 60°C to obtain a surfactant solution;

[0038] 5) Mix and stir the solution containing Ba, Sr, Mg obtained above, the solution containing Ti, and the surfactant solution, and then slowly add ammonia water to adjust its pH=2 to obtain oleic acid-modified Ba 0.5 Sr 0.5 TiO 3 MgO precursor solution;

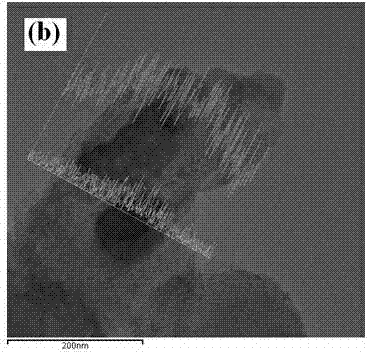

[0039] 6) Add the above Ba 0.5 Sr0.5 TiO 3 The MgO precursor solution wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com