Method for extracting and preparing tanshinone compounds from dregs of radix salviae miltiorrhizae by virtue of saccharification pretreatment method

A technology for tanshinone and medicinal residues is applied in the field of tanshinone-based components, extraction and preparation of tanshinone-based components, which can solve the problems of inefficient and high-value utilization of danshinone medicinal residues, waste of resources, etc., so as to improve resource utilization efficiency, reduce environmental pollution, The effect of good eco-efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

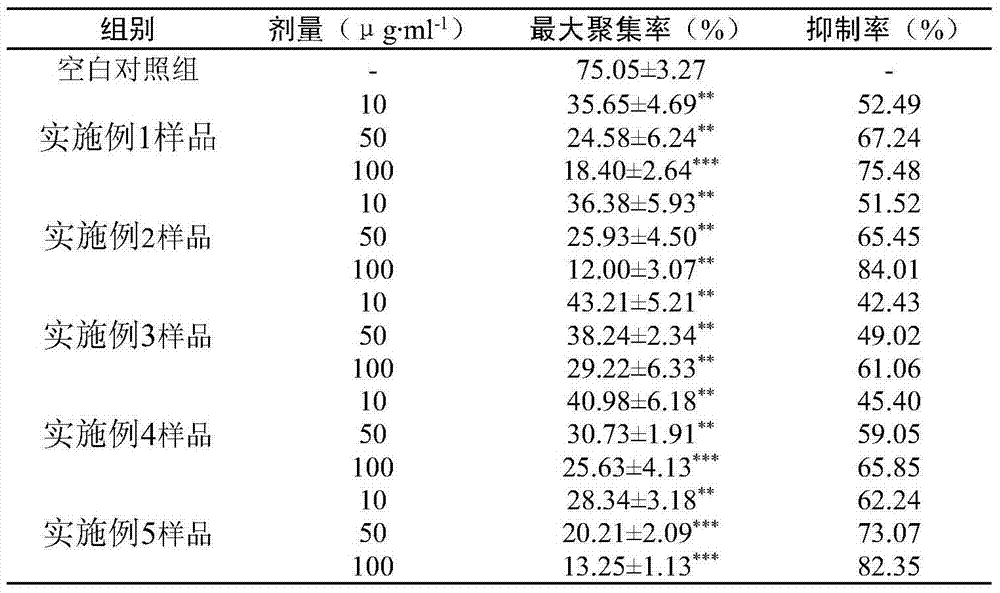

Embodiment 1

[0038] (1) Take 500g of salvia miltiorrhiza, mix it with acetic acid-sodium acetate buffer solution with a pH value of 4.8 according to the mass volume ratio of 1:1, then add cellulase solution, and place it in a constant temperature shaker at 50°C and 200r / min Carry out enzymatic hydrolysis for 24 hours;

[0039] (2) Add 500 ml of ethyl acetate to the enzymolysis solution and extract 3 times, combine the extracts, recover the solvent under reduced pressure, and obtain the concentrate;

[0040](3) Take the concentrate and dissolve it in an appropriate amount of ethanol solution, mix the sample, apply D101 macroporous adsorption resin, use 10%, 30%, 50%, 70%, 90% ethanol to elute, collect 70% ~ 90% ethanol to wash Deliquification, concentration under reduced pressure, spray drying to obtain the total tanshinone extract powder, the HPLC test results show that the total tanshinone purity is 92.3%, wherein the weight percentage of tanshinone IIA is 36.92%, and the weight percentag...

Embodiment 2

[0042] (1) Take 500g of salvia miltiorrhiza dregs, mix it with acetic acid-sodium acetate buffer solution with a pH value of 4.8 according to the mass volume ratio of 1:2, then add cellulase solution, and place it in a constant temperature shaker at 50°C and 200r / min. Enzymolysis for 24 hours;

[0043] (2) Add 8% Na to the enzymolysis solution 2 CO 3 The solution was mixed uniformly, extracted three times with 800 ml of ethyl acetate, combined the extracts, recovered the solvent under reduced pressure, and obtained the concentrate;

[0044] (3) Take the concentrate and dissolve it in an appropriate amount of ethanol solution, mix the sample, apply D101 macroporous adsorption resin, use 15%, 30%, 50%, 70%, 95% ethanol to elute, collect 70% ~ 95% ethanol to wash Deliquification, concentration under reduced pressure, spray drying to obtain the total tanshinone extract powder, the HPLC detection results show that the total tanshinone purity is 90.06%, wherein the tanshinone IIA ...

Embodiment 3

[0046] (1) Take 500 g of Danshen herb dregs, mix them with 10% HCl solution according to the mass volume ratio of 1:2, and put them in a water bath at 50°C for acidolysis for 24 hours;

[0047] (2) Take the hydrolyzed solution to adjust the pH value to neutral, add 500ml of ethyl acetate for solvent extraction 3 times, combine the extracts, recover the solvent under reduced pressure, and obtain the concentrate;

[0048] (3) Dissolve the concentrate in an appropriate amount of ethanol solution, mix the sample, apply AB-8 macroporous adsorption resin, use 10%, 30%, 50%, 70%, 95% ethanol to elute, and collect 70% to 95% The ethanol eluate is concentrated under reduced pressure and spray-dried to obtain the total tanshinone extract powder. The HPLC detection results show that the total tanshinone purity is 70%, wherein the tanshinone IIA weight percent is 22.52%, and the tanshinone I weight percent The content is 21.98%, the weight percentage of cryptotanshinone is 5.27%, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com