Crystallized coating

A coating and mass percentage technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of high accuracy of coating formulations, poor quality stability of grain texture coatings, and complicated construction procedures, so as to shorten the baking time, Clear texture and environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

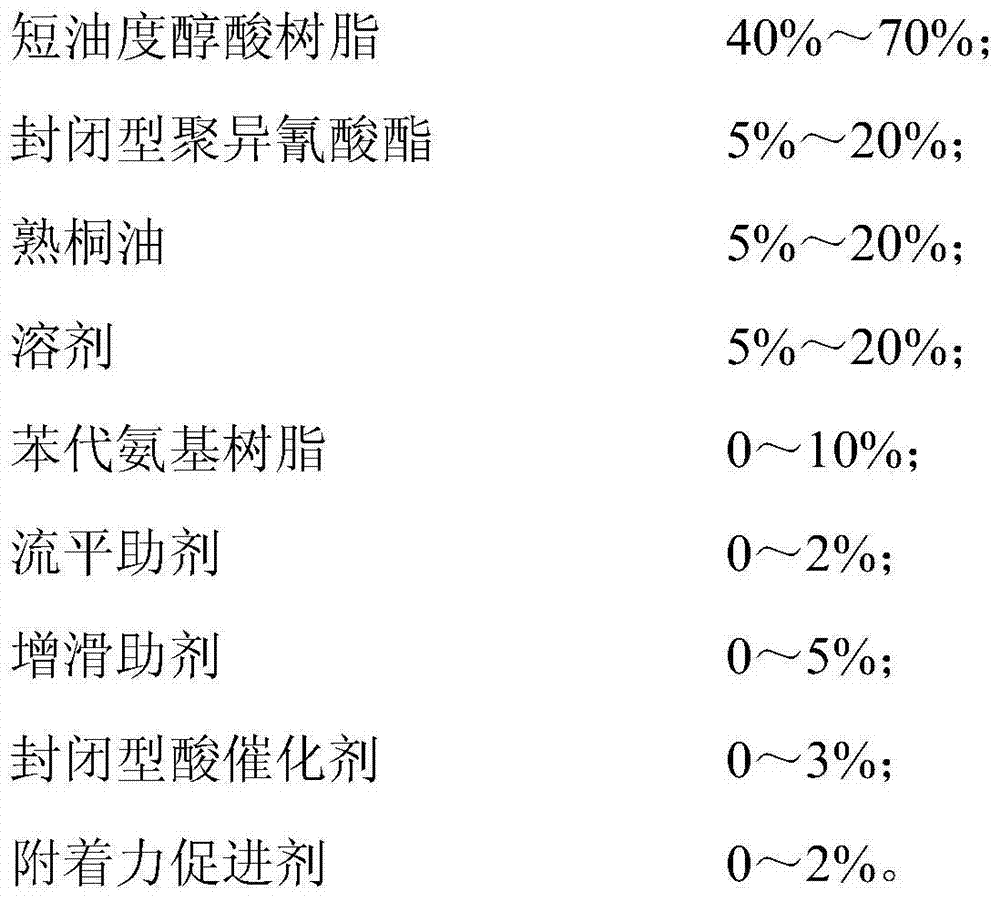

[0035] A kind of crystal texture coating provided by the present embodiment, by mass percentage, comprises the following components:

[0036]

[0037]

[0038] Wherein, the short-oil alkyd resin is formed by condensation polymerization of glycerin, phthalic anhydride and soybean oil, wherein the mass percentage of soybean oil is 35%, and the mass percentage of phthalic anhydride is 30%. Blocked polyisocyanate is a polymer produced by the reaction of polyisocyanate and ethylene glycol monobutyl ether, in which polyisocyanate is composed of toluene diisocyanate, diphenylmethane diisocyanate and 1,6-hexamethylene diisocyanate in a molar ratio of 1:1 : 1 addition comes. The median particle size of the wax slurry was 5 μm. The cooked tung oil is cooked pure tung oil, and its extraction method is to fry the tung seeds and squeeze the oil without artificially adding any chemical components.

Embodiment 2

[0040] A kind of crystal texture coating provided by the present embodiment, by mass percentage, comprises the following components:

[0041]

[0042]

[0043] Among them, the short oil alkyd resin is formed by condensation polymerization of ethylene glycol, phthalic anhydride and oleic acid, wherein the mass percentage of oleic acid is 38%, and the mass percentage of phthalic anhydride is 28%. Blocked polyisocyanate is a polymer produced by the reaction of polyisocyanate and caprolactam, in which polyisocyanate is obtained by adding toluene diisocyanate and 1,6-hexamethylene diisocyanate in a molar ratio of 1:1. The wax powder has a median particle size of 15 μm. The cooked tung oil is cooked pure tung oil, and its extraction method is to fry the tung seeds and squeeze the oil without artificially adding any chemical components.

Embodiment 3

[0045] A kind of crystal texture coating provided by the present embodiment, by mass percentage, comprises the following components:

[0046]

[0047] Wherein, the short oil alkyd resin is formed by condensation polymerization of pentaerythritol, phthalic anhydride and castor oil, wherein the mass percentage of castor oil is 36%, and the mass percentage of phthalic anhydride is 35%. Blocked polyisocyanate is a polymer produced by the reaction of polyisocyanate and imidazole, in which polyisocyanate is obtained by adding diphenylmethane diisocyanate and 1,6-hexamethylene diisocyanate in a molar ratio of 1:1. The wax powder has a median particle size of 500 nm. The cooked tung oil is cooked pure tung oil, and its extraction method is to fry the tung seeds and squeeze the oil without artificially adding any chemical components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com