Antifreezing fluid and preparation method thereof

A technology of antifreeze and antifreeze, applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of not intuitively pointing out antifreeze, not in-depth study of the influence of colorant on the cooling system, etc., to achieve high boiling point, high The effect of reserve alkalinity and stabilize PH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

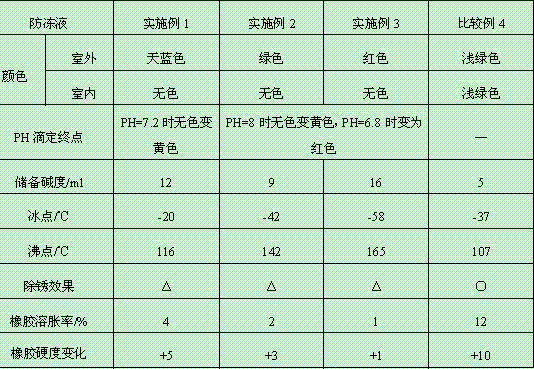

Embodiment 1

[0039] According to the formula weight ratio, add 17 parts of ethylene glycol and 3 parts of triethylene glycol into the reaction tank, and add 78 parts of deionized water, 0.05 parts of DF-830, and 5.0 parts of TF-SNA to compound agent, 1.0 parts of sodium benzoate, 2.4 parts of KRB-3B neutral rust remover and 0.2 parts of p-phenylenediamine anti-aging agent, and then add 0.2 parts of phosphate and 0.3 parts of oxalic acid after the dispersion is uniform. The pH of the system is 8.5. Finally, add 0.02 parts of ultraviolet photochromic powder and 0.1 parts of cresol red, and the antifreeze is prepared after uniform dispersion.

Embodiment 2

[0041]Add 40 parts of ethylene glycol, 6 parts of 1,2-propanediol and 6 parts of tripropylene glycol into the reaction tank according to the weight ratio of the formula. While stirring, add 47 parts of deionized water, 0.1 part of CF-190, 3.5 1 part of TF-SB compound agent, 0.8 part of sodium benzoate, 1.5 part of EVAPO-RUST rust remover and 0.8 part of p-phenylenediamine anti-aging agent, after dispersing evenly, add 0.1 part of sodium hydroxide and 0.5 part of sebacic acid, the system The pH is 8.2, and finally add 0.05 parts of ultraviolet photochromic powder and 0.2 parts of neutral red, and the antifreeze is prepared after uniform dispersion.

Embodiment 3

[0043] Add 65 parts of ethylene glycol, 12 parts of 1,2-propanediol and 15 parts of dipropylene glycol into the reaction tank according to the weight ratio of the formula, add 0 parts of deionized water, 0.2 parts of DF-830, 2 Part of TF-SNA compound agent, 0.5 part of sodium benzoate, 0.3 part of KRB-3B neutral rust remover and 1.0 part of p-phenylenediamine anti-aging agent, and then add 0.3 part of phosphate, 0.4 part of oxalic acid, 0.3 parts of sebacic acid, the pH of the system is 9.0, and finally add 0.1 parts of ultraviolet photochromic powder and 0.2 parts of neutral red, and the anhydrous antifreeze is prepared after uniform dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com